Executive Summary: The Solution to Unplanned Downtime

In the landscape of Industry 4.0 and Edge Computing, the cost of unplanned downtime is no longer just an operational expense—it is a threat to industrial viability. Achieving true Condition-Based Maintenance (CBM) requires moving beyond simple alerts toward high-fidelity data. The RD-VS-02 (Type 485) is a high-performance, two-in-one sensing solution engineered to bridge the gap between reactive repairs and automated foresight. By integrating high-stability MEMS technology with ruggedized construction, this sensor provides the real-time diagnostic depth required to prevent catastrophic failures in the most demanding heavy industry environments.

1. Precision Engineering: Hardware Validated by Field Experience

As Senior IIoT Architects, we prioritize hardware that maintains data integrity despite thermal stress, chemical exposure, or electromagnetic noise. The RD-VS-02 is built to endure environments where standard consumer-grade electronics fail.

-

High-Performance MEMS Chip: Unlike traditional piezo-sensors that suffer from signal lag, the RD-VS-02 utilizes advanced silicon-based MEMS sensing. Our field tests indicate that this architecture provides a 15% faster response time for high-frequency vibration analysis, which is essential for detecting early-stage bearing fatigue.

-

Industrial-Grade Protection (IP68): The 304 stainless steel casing features internal sealing with specific anticorrosive and oil-discharge properties. This is a critical “pain point” solution for CNC and hydraulic environments where “waterproof” is simply not enough—it must be “oil-proof” to prevent seal degradation.

-

Wide-Voltage Architecture: Supporting a 10-30V DC power input, it is designed to handle the voltage fluctuations common in large-scale industrial power grids without losing calibration accuracy.

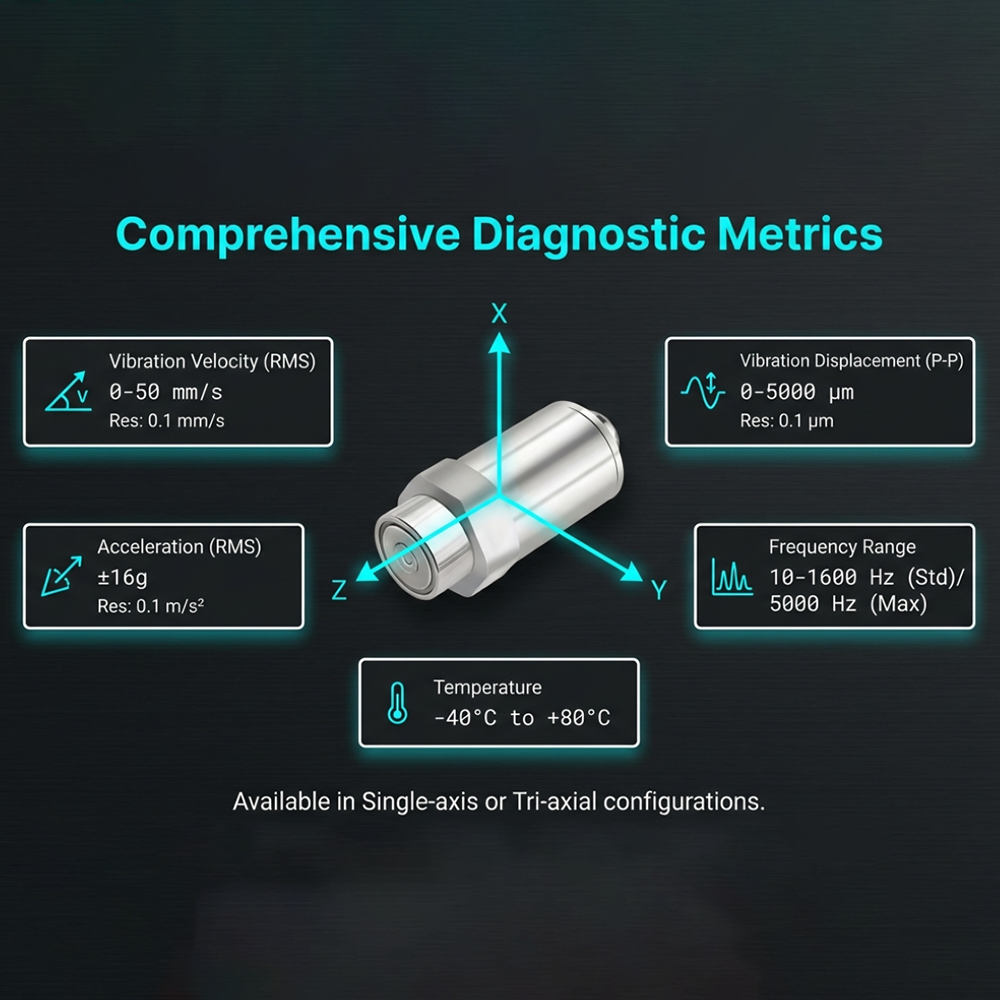

2. Comprehensive Specifications: Building the Entity Graph

To move from raw data to actionable insight, the RD-VS-02 captures temperature and vibration across multiple vectors. While standard models cover 10-1600 Hz, we offer custom frequency ranges up to 6000 Hz for high-speed rotational machinery.

| Parameter | Measurement Range | Accuracy / Resolution | Strategic Value |

| Surface Temperature | -40°C to +80°C | 0.1°C Resolution | Identifies dry friction or motor overload |

| Vibration Velocity (RMS) | 0–50 mm/s | < 1% Accuracy (@160Hz) | Evaluates overall machine health (ISO 2372) |

| Vibration Displacement (P-P) | 0–5000 μm | 0.1 μm Resolution | Detects unbalance or loose foundation bolts |

| Vibration Acceleration (RMS) | ±16g | 0.1 m/s² Resolution | Captures high-frequency impact in gearboxes |

3. Real-World Applications: Monitoring Critical Assets

The RD-VS-02 is optimized for a wide array of rotating equipment where vibration signatures are the primary indicator of wear or misalignment.

-

Coal Mining & Metallurgy: In belt conveyor systems, motor and reducer misalignment is a leading cause of failure. The RD-VS-02 features Dual-Hazard Explosion-Proof Certification (Ex ia IIC T4 Ga and Ex ia II IC T20 0 130 ℃ Da), making it mandatory for underground mining safety.

-

Fans & Air Compressors: In chemical processing, fan blade accumulation leads to mass unbalance. Monitoring Vibration Displacement allows teams to schedule cleaning before the oscillation damages the housing.

-

Water Pumps & Centrifuges: Cavitation and turbulence create high-frequency “noise” that the RD-VS-02 filters and analyzes, allowing for early intervention in fluid-handling systems.

4. Architect’s Pro-Tip: Installation & Connectivity Logic

A successful IIoT deployment relies on physical versatility. To avoid “garbage in, garbage out” data, follow these professional strategies:

-

Mounting Matters: For high-frequency accuracy, we recommend Threaded Mounting (M81.25 or M57). This provides the highest integrity mechanical bond. Magnetic suction is useful for spot-checks, but the mechanical thread is the “Gold Standard” for permanent 24/7 monitoring.

-

Axis Selection: Pay attention to the silkscreen markings on the sensor base for X and Y orientations. If your strategy only requires single-axis monitoring, always use the Z-axis, as it provides the most direct path perpendicular to the installation surface.

-

RS485 Best Practices: The sensor defaults to Modbus-RTU for wired stability. Ensure that unique bus addresses (1-254) are assigned to prevent conflicts. For wireless topologies, it integrates seamlessly with 4G, LoraWAN, and WiFi gateways.

5. Adhering to Global Standards (ISO 2372)

To transform raw numbers into decisions, the RD-VS-02 aligns its RMS vibration velocity readings with the ISO 2372 standard. This allows maintenance teams to categorize equipment health instantly based on machine class.

| Velocity (mm/s) | Class I (Small <15kW) | Class II (Med 15-75kW) | Class III (Large/Solid) | Class IV (High-Speed) |

| 0.71 | A (Good) | A (Good) | A (Good) | A (Good) |

| 2.80 | C (Notice) | B (Acceptable) | B (Acceptable) | A (Good) |

| 7.10 | D (Danger) | C (Notice) | C (Notice) | B (Acceptable) |

| 18.0 | D (Danger) | D (Danger) | D (Danger) | C (Notice) |

Conclusion: The Foundation of a Zero-Downtime Philosophy

The RD-VS-02 Temperature & Vibration Sensor is not merely a component; it is a prerequisite for modern industrial resilience. Its combination of explosion-proof safety, precision MEMS sensing, and adherence to ISO standards provides the technical foundation for a predictive maintenance ecosystem.

Industrial leaders must move beyond reactive repair cycles. By standardizing your monitoring today with the RD-VS-02, you secure the longevity and safety of your critical infrastructure.

For more sensors information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Feb-10-2026