As the global energy landscape shifts toward the hydrogen economy and indoor air quality becomes a paramount health concern, the demand for sophisticated sensing technology is reaching an all-time high. Recent breakthroughs in nanotechnology and artificial intelligence (AI) are transforming the gas sensor from a simple measurement tool into a proactive safety system. From industrial chemical plants to smart home environments, these devices serve as invisible guardians against both visible and invisible risks.

The Technological Frontier:

Speed, Precision, and AI The industry is currently witnessing a paradigm shift driven by material science and intelligent integration.

Material and Miniaturization Breakthroughs

Recent research has introduced two-dimensional nanomaterials, such as MXene, which allow a hydrogen sensor to achieve response times as fast as 0.8 seconds. These materials offer sensitivity levels 20 times higher than traditional palladium-based alternatives and provide significantly improved resistance to humidity. Furthermore, miniaturization efforts have led to chip-scale sensors measuring just 2x2mm, enabling the integration of gas detection into wearable devices with 90% lower power consumption.

AI and Machine Learning Integration

Modern units, such as the Aera AI air quality monitor, now incorporate machine learning to detect up to 12 parameters—including PM2.5, VOCs, and CO2. These systems are moving beyond reactive alerts to “prevention systems” that learn user habits and predict air quality changes, automating smart home responses before pollutants reach dangerous levels.

Industrial-Grade Performance and Features

High-performance gas detection equipment must withstand harsh environments while maintaining absolute accuracy. The latest industrial-grade sensors are designed with a focus on durability and ease of use.

Key Product Features

• High Precision & Sensitivity: Utilizing high-quality industrial gas components subjected to strict multi-point calibration.

• Robust Construction: Industrial-grade aluminum shell that is waterproof, dustproof, and explosion-proof.

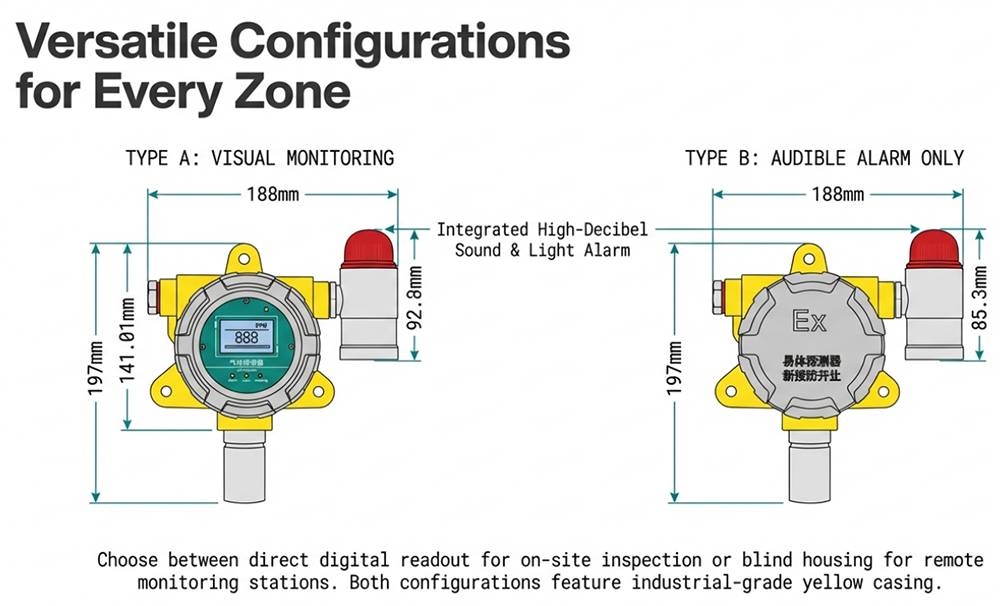

• Dual Display Options: Available with a light-emitting diode digital display or a non-display version where data is read via a PC-side interface.

• Advanced Control: Equipped with infrared remote control technology, allowing operators to modify parameters and alarm points without disassembling the unit.

• Diverse Output Protocols: Supports RS485, 4-20mA, 0-5V, and 0-10V, with wireless connectivity options including WiFi, GPRS, 4G, and LoRaWAN.

Technical Specifications Table

|

Feature

|

Specification

|

|---|---|

|

Power Supply

|

DC 10~30V

|

|

Housing Material

|

Industrial-grade Aluminum (Explosion-proof)

|

|

Calibration

|

Three-point strict calibration (Provincial Metrology Institute checked)

|

|

Alarm System

|

High and low alarm points; optional sound and light alarm

|

|

Connectivity

|

RS485, WiFi, 4G, LoRa, LoRaWAN

|

|

Mounting

|

Wall-mounted via expansion screws

|

|

Warranty

|

One year

|

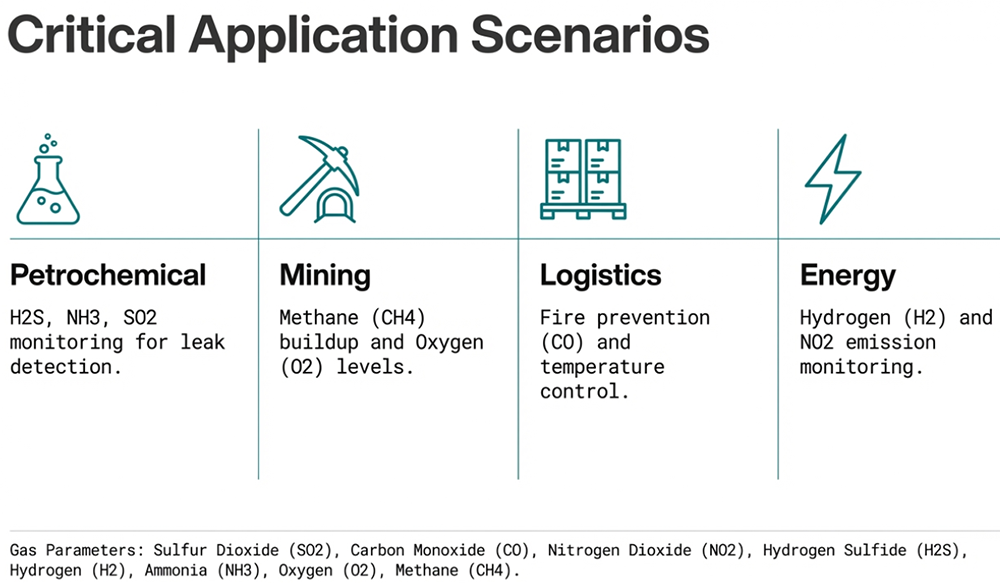

Critical Application Scenarios

The versatility of modern gas sensor technology allows for deployment across a wide range of sectors:

1. Hydrogen Safety: With the global hydrogen fuel cell vehicle market expanding, a reliable hydrogen sensor is a rigid requirement for leak detection at refueling stations. The market for these sensors is forecasted to reach $3.7 billion by 2024.

2. Air Quality Monitoring: Post-pandemic health awareness has seen sales of the smart air quality monitor increase by 320% year-on-year. New regulations, such as the EU’s Indoor Air Quality Directive, will mandate real-time monitoring in public buildings by 2026.

3. Industry 4.0: In chemical plants and lithium battery facilities, distributed sensor networks create real-time “gas maps” to predict anomalies and prevent accidents.

4. Smart Cities: Integration of wireless sensors into urban infrastructure, such as streetlights, provides grid-based data to help citizens avoid highly polluted routes.

FAQ:

Q: Can these sensors detect multiple types of gases?

A: Yes. While specific models are optimized for a primary gas (such as Oxygen, Methane, or Hydrogen), the platform supports a wide range of parameters including Sulfur dioxide, Carbon monoxide, Nitrogen dioxide, Hydrogen sulfide, Ammonia, and even Temperature and Humidity.

Q: How are the sensors calibrated for accuracy?

A: Every unit undergoes a strict three-point calibration process. The hardware uses high-quality industrial components that are checked by the Provincial Metrology Institute to ensure consistency and high precision.

Q: Is it possible to change settings without opening the device?

A: Yes. The units feature remote infrared control technology, which allows for the modification of parameters and alarm points safely and conveniently without disassembly.

Q: What are the installation requirements?

A: The devices are designed for wall mounting. Installation involves drilling a 10mm hole, inserting an expansion tube, and securing the device with a screw cap. For marine or specialized environments, sensors can be connected via LoRaWAN collectors to monitor levels at specific depths (e.g., 5m or 10m).

Q: How is the data monitored remotely?

A: Data can be transmitted via wireless modules (WiFi, 4G, LoRaWAN) to a matched server and software, allowing for real-time data visualization on a PC or mobile device.

Tags: gas sensor | hydrogen sensor | air quality monitor

For more gas sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-19-2026