1. Introduction: The Direct Answer for High-Performance Ammonia Monitoring

The best industrial ammonia sensors for 2026 combine high accuracy with a focus on long-term cost-effectiveness. Top-tier models feature a replaceable membrane head to significantly reduce total lifecycle costs, and incorporate a built-in reference electrode with temperature compensation for consistently precise measurements. This modern design breaks the old model of complete unit replacement, thereby maximizing uptime and minimizing operational expenses. This guide details the critical features, technical specifications, and application scenarios of high-performance industrial water ammonia sensors, helping you make an informed purchasing decision.

2. The Hidden Costs and Inaccuracies of Traditional Ammonium Sensors

Project managers and facility operators often face significant recurring expenses with traditional ammonium sensors. These older models typically have a short service life, often around three months. Their core flaw lies in the design: when the critical sensitive membrane head is damaged or fails, the entire sensor unit must be discarded and fully replaced. This frequent full-unit replacement cycle leads to unexpectedly high maintenance costs and operational downtime, impacting both budgets and data consistency.

Understanding Sensor Lifespan and Maintenance Costs

The need to replace the entire sensor every quarter is a common financial pitfall in water quality monitoring projects. This outdated model makes long-term continuous monitoring a costly investment.

3. Core Features of an Upgraded Industrial Ammonia Sensor

Modern industrial ammonia sensors are engineered to eliminate the high-cost maintenance cycles and data inaccuracies of traditional models. They integrate key design upgrades focused on extending service life, improving measurement accuracy, and ensuring reliable performance in demanding field environments.

3.1. Revolutionary Cost Savings: The Replaceable Membrane Head

The most significant upgrade for reducing Total Cost of Ownership (TCO) is the replaceable membrane head. Unlike traditional sensors that are a single, disposable unit, this modern design allows for the replacement of only the membrane head. When the membrane is damaged or reaches end-of-life, the sensor’s core body and electronics remain in use. This feature dramatically lowers the sensor’s lifecycle cost by turning a major capital expenditure into a minor maintenance task.

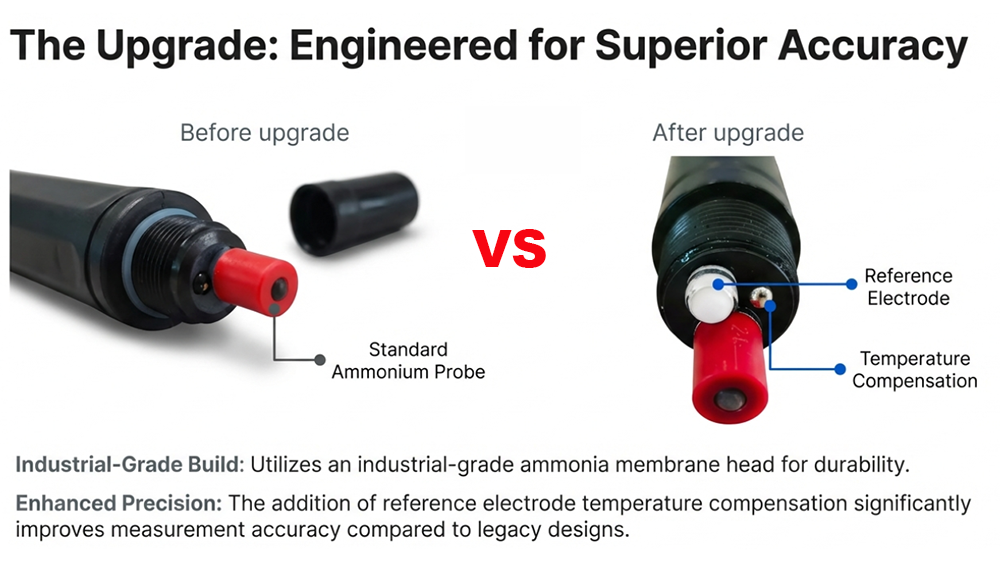

3.2. Unmatched Accuracy: Industrial-Grade Design with Temperature Compensation

To ensure reliable and precise data, the upgraded sensor utilizes an industrial-grade ammonia-sensitive membrane head. Crucially, its upgraded design integrates two components absent in older models: a reference electrode and a temperature compensation element. This integrated approach corrects for environmental variables in real-time, significantly enhancing measurement accuracy compared to simple ammonium ion electrodes.

3.3. Built for Demanding Environments: Durability and Signal Integrity

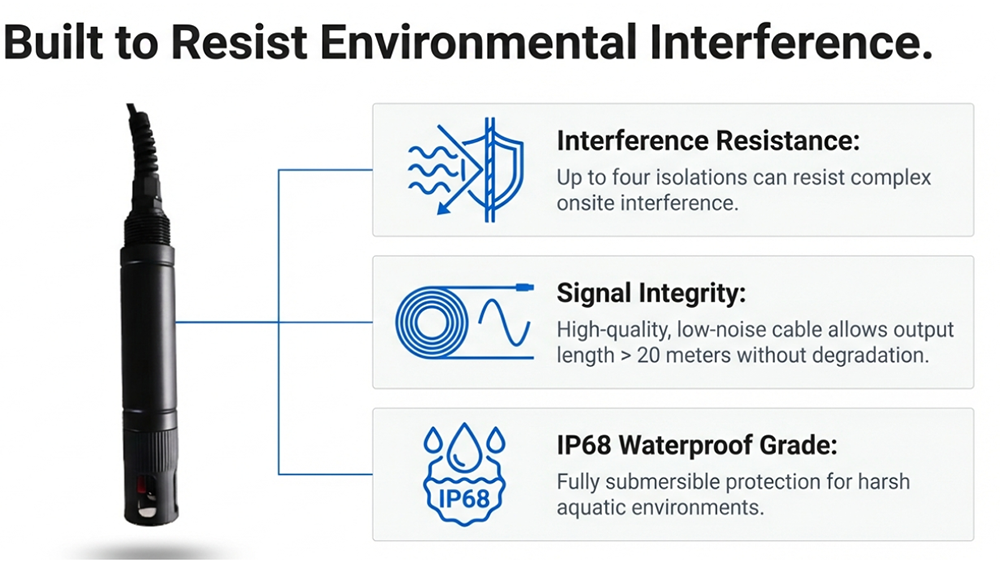

This sensor is designed for robust operation in complex industrial and environmental settings.

- IP68 Waterproof Rating: The housing is fully protected against dust ingress and prolonged immersion, ensuring reliability in submerged applications.

- Resistance to Complex Interference: The design incorporates up to four layers of isolation to resist complex electromagnetic interference common at industrial sites, protecting signal integrity.

- Long-Distance Signal Transmission: Standard high-quality, low-noise cable supports signal output over 20 meters. For long-distance industrial installations, the RS485 communication protocol supports lead lengths up to 1000 meters, ensuring reliable data transmission across large sites.

- Overall Performance: The sensor is characterized by good stability, high integration in a compact size, low power consumption, and a long overall service life.

4. Technical Specifications at a Glance: A Clear Data Table

| Parameter | Specification Value |

|---|---|

| Measurement Range (Water Ammonia) | 0.1 – 1000 ppm |

| Resolution (Water Ammonia) | 0.01 ppm |

| Accuracy (Water Ammonia) | ±0.5% FS |

| Measurement Range (Water Temp) | 0 – 60 °C |

| Resolution (Water Temp) | 0.1 °C |

| Accuracy (Water Temp) | ±0.3 °C |

| Measuring Principle | Electrochemical Method |

| Digital Output | RS485, MODBUS Protocol |

| Analog Output | 4-20mA |

| Housing Material | ABS |

| Operating Environment Temp | 0 ~ 60 °C |

| Protection Level | IP68 |

5. Key Application Scenarios for Real-Time Ammonia Monitoring

Combining robust design, precise measurement, and remote monitoring capabilities, this industrial ammonia sensor is ideal for the following critical B2B applications:

- Aquaculture & Fish Farming: Continuous monitoring of ammonia levels is essential to prevent toxic conditions and ensure the health and productivity of aquatic stocks.

- Environmental Water Monitoring: Used by agencies and researchers to track pollutants and assess the health of rivers, lakes, and groundwater systems in real-time.

- Industrial Wastewater Treatment: Crucial for process control within treatment plants and for ensuring discharged effluent complies with stringent environmental regulations.

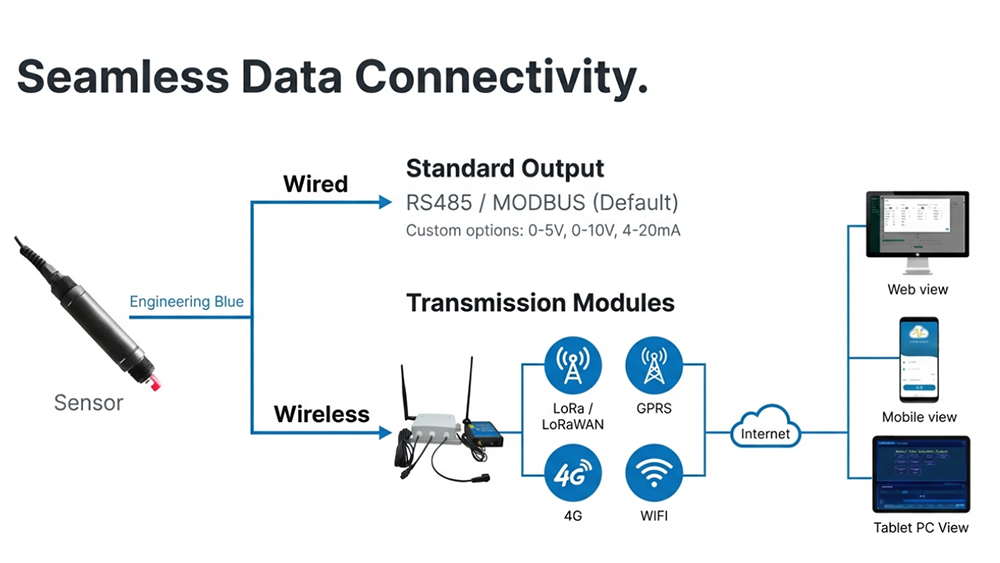

6. From an Engineer’s Perspective: System Integration Guide

From an integration standpoint, this sensor offers notable flexibility. It comes standard with RS485 communication output supporting the MODBUS protocol, a universal standard in industrial environments. More importantly, it is compatible with a variety of wireless modules, including GPRS, 4G, WIFI, LORA, and LoRaWAN. This allows you to build a complete, customized remote monitoring solution tailored to your site’s needs. Data can be transmitted directly from the field to a central server, enabling real-time viewing on PCs, mobile phones, or tablets, creating a powerful and efficient data acquisition system.

7. Conclusion: Make the Smart Choice for Your Monitoring Project

Selecting the right ammonia sensor is a critical decision that impacts both data quality and long-term budget. The upgraded industrial sensor provides a superior solution by delivering high accuracy and durability while directly addressing the high lifecycle costs of older models. The replaceable membrane head is a game-changing feature that offers a significantly lower Total Cost of Ownership, making it the smart and forward-thinking choice for any serious water quality monitoring project.

8. Take the Next Step

Ready to upgrade your monitoring capabilities? Our team is here to assist you.

We can also provide a variety of solutions for

1. Handheld meter for multi-parameter water quality

2. Floating Buoy system for multi-parameter water quality

3. Automatic cleaning brush for multi-parameter water sensor

4. Complete set of servers and software wireless module, supports RS485 GPRS /4g/WIFI/LORA/LORAWAN

For more water sensors information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-12-2026