The silent workhorses of industry—sensors monitoring water levels in vast treatment tanks, chemical levels in process vessels, and flow in critical pipelines—are undergoing a quiet revolution. At the forefront are three interconnected technologies: 80GHz radar sensors with a narrow 6° beam and ±1mm accuracy, robust RS485 communication, and intelligent flow meters. Together, they solve age-old industrial challenges and unlock unprecedented efficiency, safety, and data insight.

1. The Accuracy Breakthrough: 80GHz Radar’s Sharp Focus

For years, non-contact level measurement meant compromises. Older 26GHz radar sensors used wider beam angles that reflected off tank walls or internal equipment, causing false echoes.

The move to 80GHz Frequency-Modulated Continuous Wave (FMCW) radar is a game-changer:

- Extremely Narrow Beam (6°): This focused energy acts like a laser pointer, penetrating through steam and ignoring internal obstructions like ladders or agitators.

- Millimeter Accuracy (±1mm): This precision translates directly into cost savings and reduced product waste for inventory management.

- Superior Signal-to-Noise Ratio: Even with low-dielectric media like certain fuels or plastics, the high-frequency beam delivers a stronger return signal.

2. The Digital Backbone: RS485 Connectivity

A precision sensor is only as good as the data it can reliably deliver. The RS485 interface is the industrial-grade highway for this millimeter-precise data.

- Long-Distance Reliability: It can transmit data clearly over 1000 meters, ideal for large plant sites.

- Network Capability: Multiple sensors can connect on a single, cost-effective 2-wire bus, simplifying cabling.

- Standard Protocols: Using Modbus RTU, it speaks a language that every PLC, SCADA system, and IIoT gateway understands.

3. The Complete Picture: Integrated Flow Measurement

Level sensing tells you “how much,” but flow measurement tells you “how fast.” Modern water flow meters with RS485 capability create a powerful synergy when paired with level data.

| Feature | 80GHz Radar Level Sensor | RS485 Flow Meter |

| Primary Data | Precise level (±1mm) | Real-time flow rate |

| Output Type | RS485 (Modbus RTU) | RS485 / Pulse Output |

| Key Advantage | Ignores tank obstructions | System mass balance checks |

Application Scenarios

Water Treatment: Monitoring narrow wells and open channels with zero interference from walls.

Chemical Processing: Precise inventory management in tanks with internal agitators or steam.

Industrial Automation: Integrating real-time flow and level data to detect leaks and optimize pump sequences.

FAQ

Q: Why choose 80GHz over 26GHz?

A: 80GHz offers a much narrower beam (6° vs. 10°+), making it easier to install in narrow spaces without false echoes.

Q: Can RS485 handle multiple sensors?

A: Yes, multiple level and flow sensors can connect to a single 2-wire bus, drastically reducing wiring costs.

The move toward 80GHz radar represents a shift from “estimation” to “exact measurement.” When paired with the reliable data pipeline of RS485 and the contextual intelligence of flow data, it creates a sensor ecosystem that is fundamentally more intelligent.

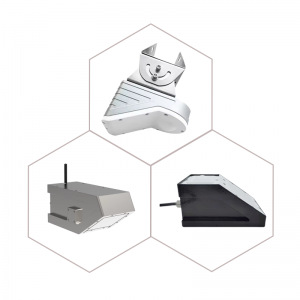

Other similar products

Tags: 80 ghz radar beam angle 6° measurement accuracy ±1 mm、water level sensor rs485、water flow meter

For more water radar flow sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-21-2026