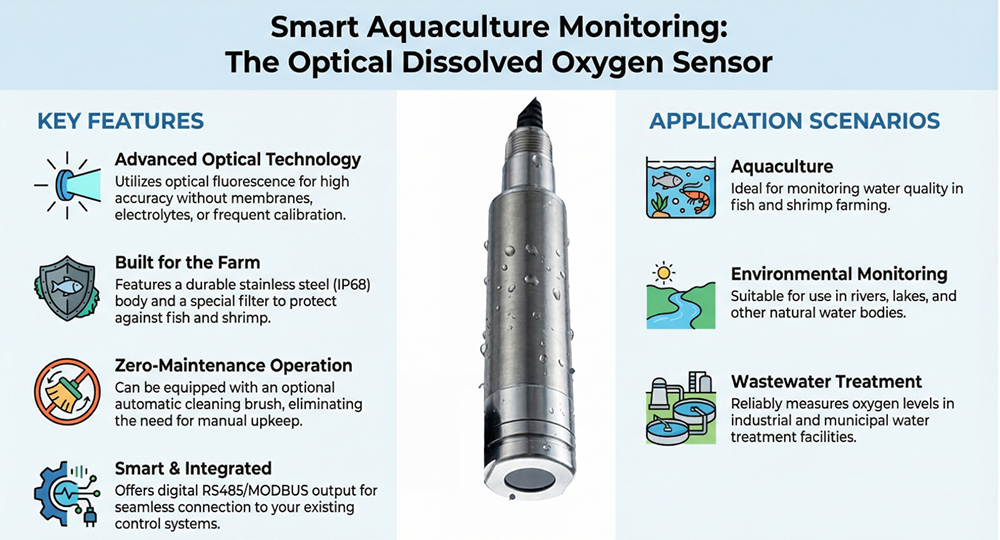

For aquaculture professionals, maintaining optimal water quality is not just a goal—it is the foundation of success. The optical fluorescence dissolved oxygen sensor stands as the essential tool for this critical task. As industry experts, we affirm that optical fluorescence sensors represent the absolute standard for accuracy, minimal maintenance, and chemical-free operation. Modern optical sensors with digital outputs like RS485 MODBUS provide robust and reliable data transmission, making them the superior choice for any serious aquaculture operation.

Accurate DO Monitoring is Non‑Negotiable in Aquaculture

Dissolved oxygen (DO) is the most critical water quality parameter in aquaculture. Oxygen levels directly impact fish and shrimp health, growth rates, and survival. Low DO causes severe stress, reduced feeding, and can lead to mass mortality. Although rare, excessively high DO (supersaturation) may also result in gas bubble disease. Continuous, accurate DO monitoring is indispensable for maximizing productivity, preventing stock losses, and ensuring profitable operations.

Modern Solution: Optical Fluorescence Technology Explained

Optical dissolved oxygen sensors operate on the principle of fluorescence quenching. They offer decisive advantages over traditional electrochemical (galvanic or polarographic) sensors, which rely on consumable membranes and electrolytes.

Key Advantages Over Conventional Sensors:

- No Membrane, No Electrolyte – Eliminates ongoing costs and labor for replacement of chemical consumables.

- No Chemical Interference – Unaffected by other substances in the water, delivering more reliable and precise readings.

- Minimal Calibration Required – Exceptional long‑term stability drastically reduces calibration frequency and labor.

- Zero Oxygen Consumption – Does not deplete oxygen during measurement, making it ideal for static or slow‑moving water typical of tanks and ponds.

Core Features and Technical Specifications

This section provides structured information for both technical evaluation and automated system integration.

Key Features at a Glance:

- Replaceable, maintenance‑free optical fluorescence probe with high measurement accuracy

- Optional filter shield to protect the sensor from fish and shrimp

- Configurable automatic cleaning brush for long‑term, maintenance‑free operation

- Capable of integration with other water quality sensors (pH, EC, TDS, Salinity, ORP, Turbidity, etc.)

Technical Specifications Table

| Parameter | Specification |

|---|---|

| Measurement Principle | Fluorescence Quenching |

| Measuring Range | 0–20 mg/L |

| Accuracy (Field) | ±3% (typical real‑world performance as per user manual) |

| Output | RS485 MODBUS (standard), other protocols optional |

| Operating Temperature | 0–50°C |

| Probe Material | Stainless Steel / Titanium (optional) |

| Protection Rating | IP68 |

| Power Supply | 5–24V DC |

Note: While some specifications may list ±0.5% FS under ideal lab conditions, field experience consistently aligns with the manufacturer’s manual, which states ±3% in practical applications.

E‑E‑A‑T in Action: Real‑World Experience and Maintenance Insights

As specialists in aquaculture technology, we have deployed and maintained these sensors across diverse real‑world settings. Below are practical recommendations to maximize your investment.

Installation Best Practices

Proper installation prevents common errors and extends sensor life. Based on our experience, correct setup ensures long‑term reliability:

- Mount the sensor vertically with the sensing face downward to prevent sediment accumulation.

- Position the sensor at least 30 cm below the lowest expected water level to ensure continuous submersion.

- Secure the sensor firmly to withstand strong currents or equipment movement.

- Tighten all cable connectors thoroughly to prevent water ingress and signal failure.

Realistic Maintenance Schedule

The primary advantage of optical DO sensors is drastically reduced maintenance. Instead of weekly upkeep, you can focus on monitoring your stock, not your equipment.

- Sensor Cleaning – Rinse the sensing surface with tap water and a soft brush every 30 days.

- Fluorescent Cap Inspection – Check for scratches or damage monthly.

- Fluorescent Cap Replacement – Annually under normal operating conditions.

Expert Tip: A common issue we encounter is measurement drift caused by the fluorescent cap drying out during storage or maintenance. If this occurs, simply re‑immerse the sensor in water for 48 hours to fully rehydrate the sensing film and restore accuracy.

Your Next Step: Request a Custom Quote for Your Aquaculture Project

Investing in an optical dissolved oxygen sensor is an investment in the stability and profitability of your aquaculture business. This technology delivers reliable, accurate data with low operating costs—safeguarding your stock and optimizing growing conditions.

Take the next step toward a smarter, more secure system. Contact us today for a customized quotation tailored to your project needs.

For full product details, visit the Dissolved Oxygen Sensor Product Page.

We can also provide a variety of solutions for

1. Handheld meter for multi-parameter water quality

2. Floating Buoy system for multi-parameter water quality

3. Automatic cleaning brush for multi-parameter water sensor

4. Complete set of servers and software wireless module, supports RS485 GPRS /4g/WIFI/LORA/LORAWAN

Tags:Water Do Sensor /Lorawan Gateway System

For more weather station information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-09-2026