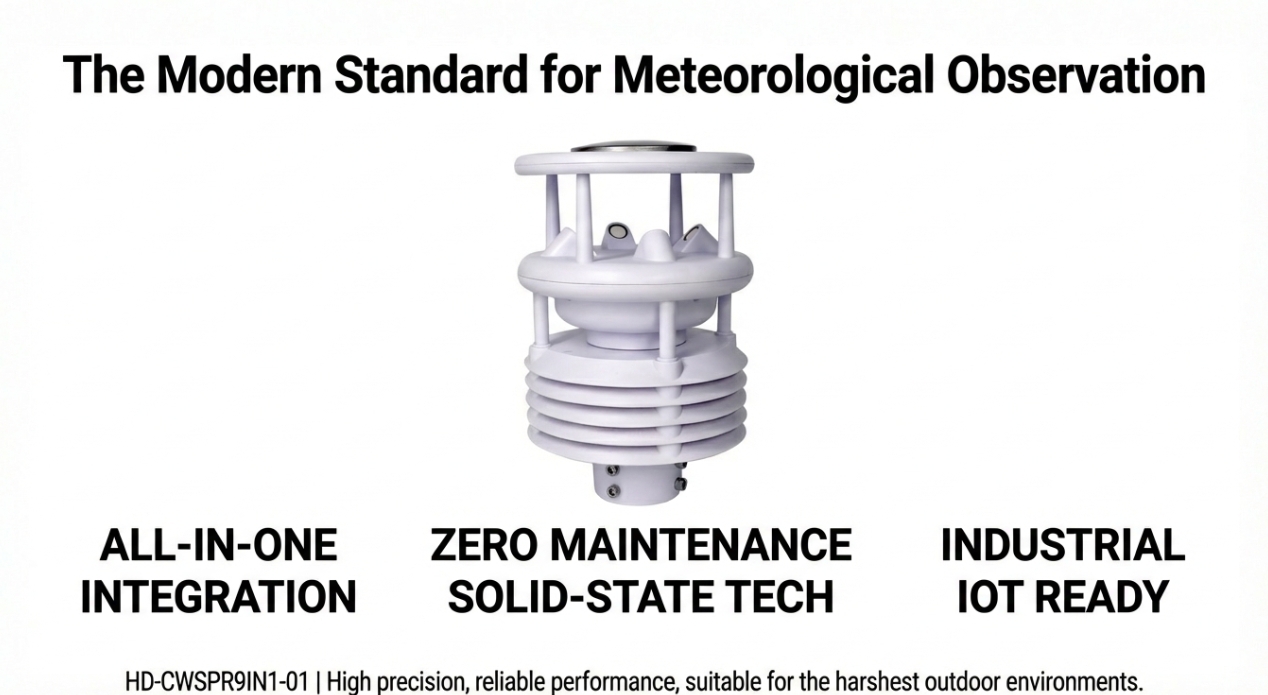

High-precision industrial weather stations, specifically the HD-CWSPR9IN1-01, are defined by the integration of solid-state sensing to ensure maintenance-free longevity in mission-critical environments. By combining ultrasonic wind measurement with piezoelectric rainfall technology, these stations eliminate the mechanical failure vectors common in traditional instruments. The inclusion of a secondary rain/snow detection sensor provides a crucial dual-stage verification layer, optimizing data reliability for autonomous IIoT deployments in solar fields, smart cities, and high-altitude infrastructure.

Why Integrated Environmental Monitoring is Shifting to “Solid-State” Technology

The industrial sector is undergoing a decisive transition from mechanical meteorological sensors to integrated, solid-state micro-meteorological instruments. From an architectural perspective, mechanical moving parts—specifically anemometer cups and wind vanes—represent the primary failure points in remote deployments. Physical wear, bearing degradation, and susceptibility to sand or heavy dust accumulation lead to significant calibration drift and eventual hardware seizure.

Adopting solid-state technology enables reliable real-time monitoring without the risk of mechanical jam-ups. Ultrasonic Wind Speed and direction sensing allow for precise measurement in extreme conditions without moving parts to freeze or wear out. Furthermore, the Piezoelectric Rainfall Sensor provides a maintenance-free alternative to traditional tipping buckets, which are notoriously prone to clogging from debris. This shift not only reduces OpEx by eliminating site visits for cleaning but also ensures the structural integrity of the data stream in the most demanding industrial environments.

Technical Performance Matrix: The HD-CWSPR9IN1-01 9-in-1 Network

The HD-CWSPR9IN1-01 is a highly integrated solution designed for 24-hour continuous online monitoring. It delivers eight standard meteorological parameters while utilizing a specialized ninth sensor—a dedicated rain and snow detector—to provide a sophisticated verification logic for precipitation data.

Comparative Technical Specifications of the HD-CWSPR9IN1-01

| Parameter | Units | Measuring Range | Resolution | Accuracy | Sensing Principle |

| Air Temperature | ℃ | -40–85℃ | 0.1℃ | ±0.3℃ (@25℃) | Digital/Capacitive |

| Relative Humidity | %RH | 0–100%RH | 0.1%RH | ±3%RH (10-80%RH, non-condensing) | Digital/Capacitive |

| Air Pressure | hPa | 300–1100hPa | 0.1hPa | ≦±0.3hPa (@25℃, 950–1050hPa) | Digital/Piezoresistive |

| Wind Speed | m/s | 0–60m/s | 0.01m/s | ±(0.3+0.03v)m/s (≤30m/s); ±(0.3+0.05v)m/s (≥30m/s) | Ultrasonic |

| Wind Direction | ° | 0–360° | 0.1° | ±3° (Wind speed <10m/s) | Ultrasonic |

| Rainfall | mm/h | 0–200mm/h | 0.1mm | Error <10% | Piezoelectric |

| Illuminance | KLUX | 0–200KLUX | 10LUX | Reading 3% or 1% FS | Optical |

| Solar Radiation | W/m² | 0–2000 W/m² | 1 W/m² | Reading 3% or 1% FS | Thermopile/Optical |

| Rain & Snow | Binary | Yes/No | N/A | Logic Gate Verification | Conductivity |

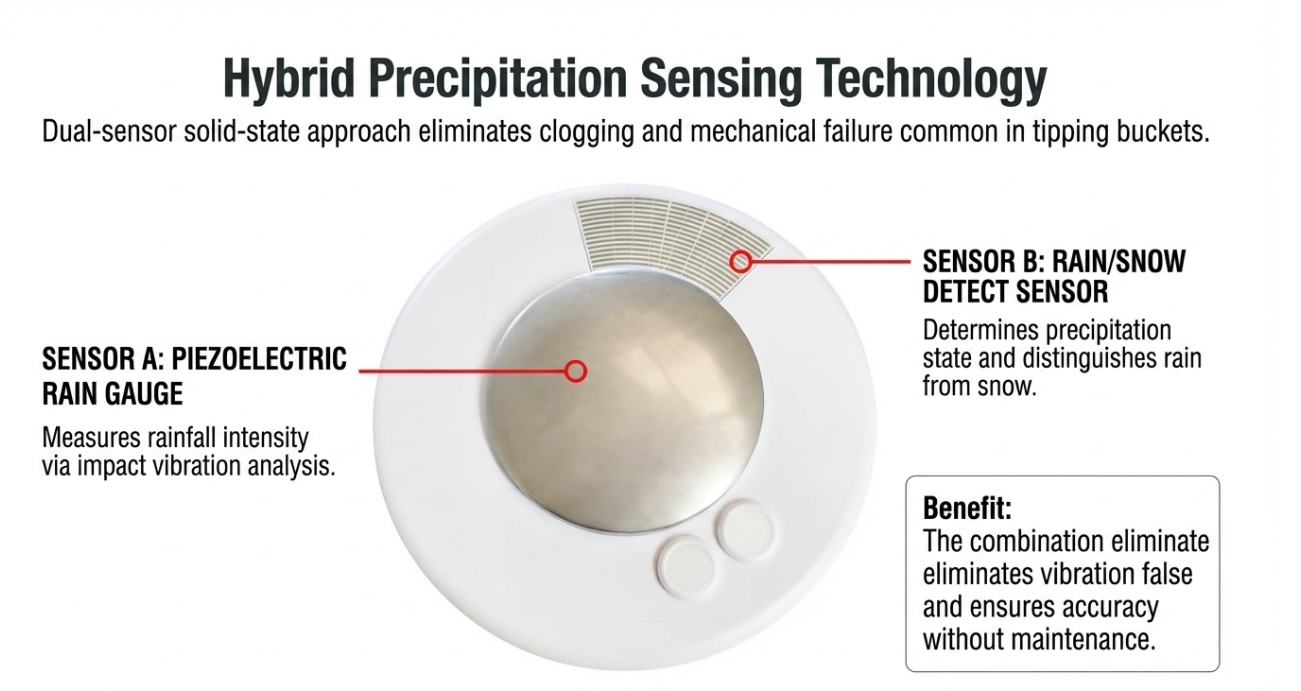

Dual-Stage Precipitation Verification: The 9th Element Logic

The strategic advantage of the HD-CWSPR9IN1-01 lies in its “9-in-1″ architecture. While many industrial units rely solely on a piezoelectric sensor for rainfall measurement, this model integrates a dedicated Rain and Snow Sensor as a secondary verification layer.

In high-vibration environments—such as bridges or towers—piezoelectric sensors can occasionally generate false positives due to structural resonance. The HD-CWSPR9IN1-01 uses the rain and snow sensor as a “logic gate”: the system only records significant precipitation when both the piezoelectric vibration and the surface conductivity of the rain/snow sensor align. This dual-stage verification drastically reduces data noise and ensures high-fidelity precipitation reporting.

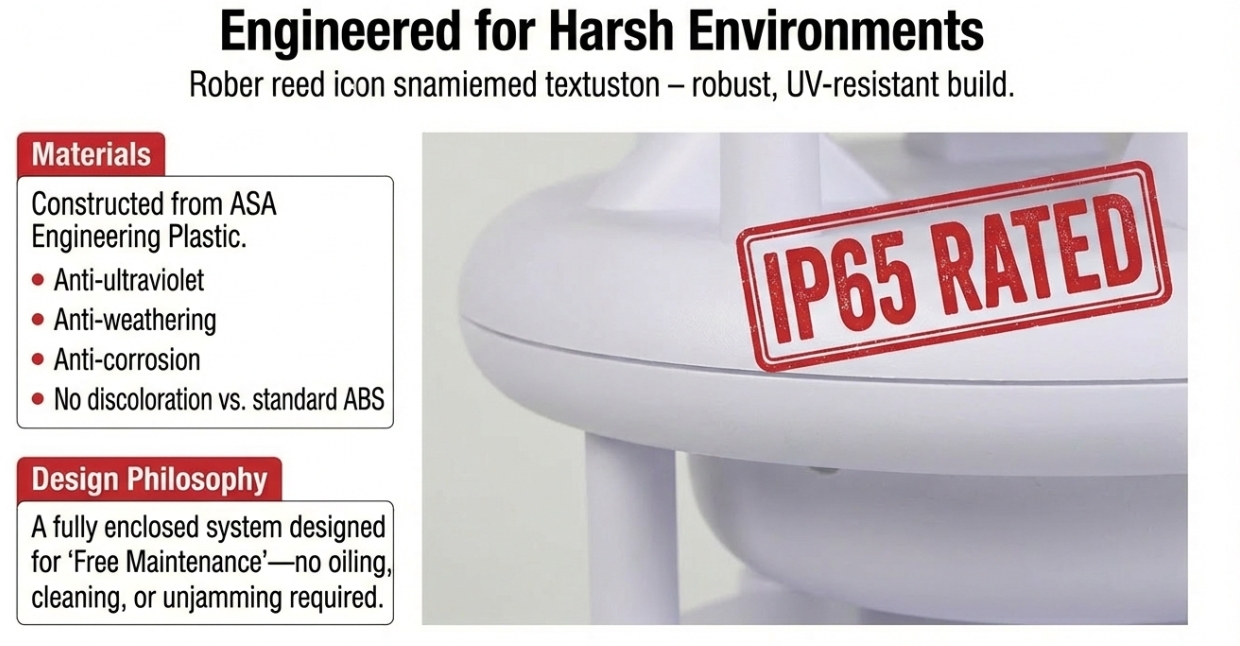

Strategic Advantages of ASA Engineering Plastics in Extreme Environments

The material science of the station’s housing is engineered for survival. The HD-CWSPR9IN1-01 utilizes high-grade ASA engineering plastic, a material superior to standard ABS for industrial outdoor use.

- Anti-Ultraviolet & Thermal Reflectivity: ASA is specifically formulated to resist UV degradation. Its high thermal reflectivity prevents internal overheating of the air temperature and humidity sensors, maintaining measurement accuracy during solar peaks.

- Anti-Weathering & Structural Integrity: The material maintains its impact strength and remains non-brittle across the full -40°C to +85°C operating range.

- Corrosion Resistance: ASA’s chemical resistance profile mitigates degradation in high-salinity coastal environments and industrial zones with acidic atmospheric conditions.

- Zero Discoloration: Long-term exposure does not lead to the yellowing or “chalking” typical of lesser plastics, ensuring the station’s longevity and professional aesthetic on-site.

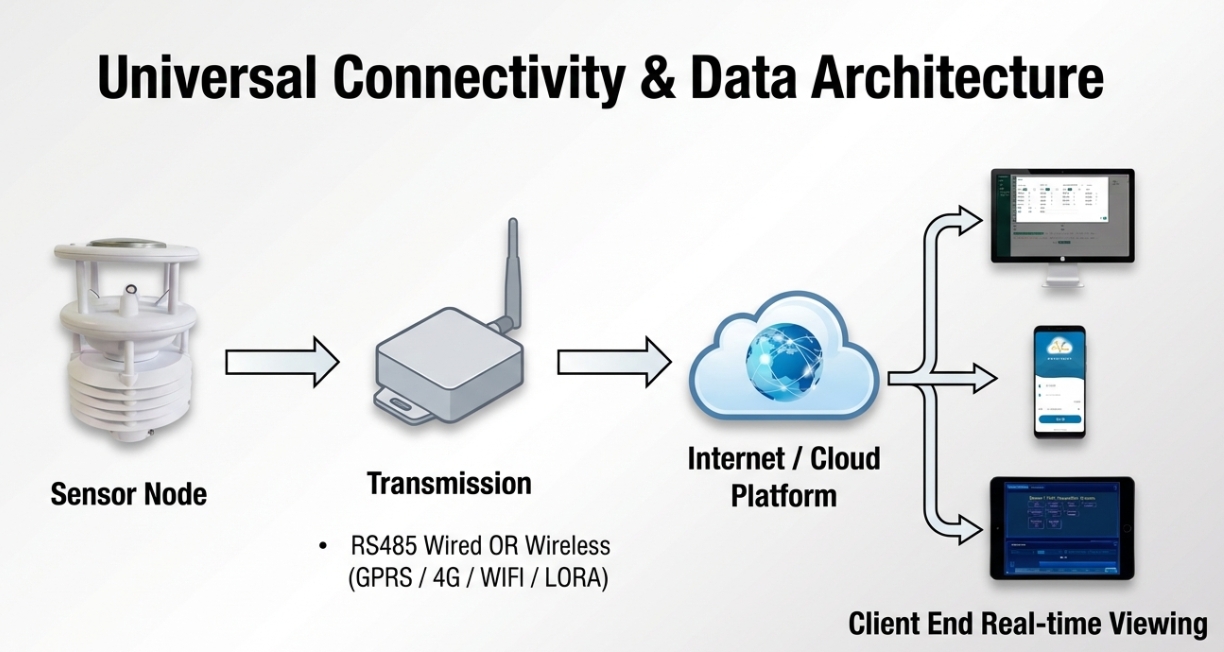

Connectivity & The Digital Ecosystem: RS485 to Cloud

The hardware architecture is optimized for seamless Industrial IoT (IIoT) integration through robust communication protocols:

- Wired Industrial Interface: Standard output is RS485 using the Modbus RTU protocol, allowing for direct integration into PLC, SCADA, or existing building management systems.

- Advanced Customization: System integrators can customize Baud Rates (from 9600 to 115200) and configure Active Reporting Cycles (via register 0x010A) to meet specific data polling requirements.

- Wireless Expansion: For remote deployments, the station integrates with wireless data collectors supporting GPRS, 4G, WiFi, LoRa, and LoRaWAN.

- End-to-End Visualization: Data flows from the solid-state sensors to a wireless collector, then to the cloud, where it is visualized via Web, Mobile, or Tablet PC View for real-time decision-making.

Industry-Specific Applications: From Solar Fields to Smart Cities

Photovoltaic (PV) Stations

In solar energy management, the integration of Solar Radiation and Illuminance sensors is critical for calculating the Performance Ratio (PR) of the field. By correlating real-time irradiance with electrical output, operators can identify panel degradation or cleaning requirements.

High-Altitude Infrastructure

For power transmission towers and high-altitude iron towers, the ultrasonic wind sensor provides vital structural safety data. The absence of moving parts prevents the sensor from seizing in freezing rain or high-altitude icing conditions, ensuring wind-load data is never lost.

Smart Cities and Agriculture

The modular layout and low power consumption (<1W @ 12V) allow for cost-effective grid deployment. In smart city applications, these sensors provide hyper-local weather intelligence for traffic safety and urban heat island monitoring.

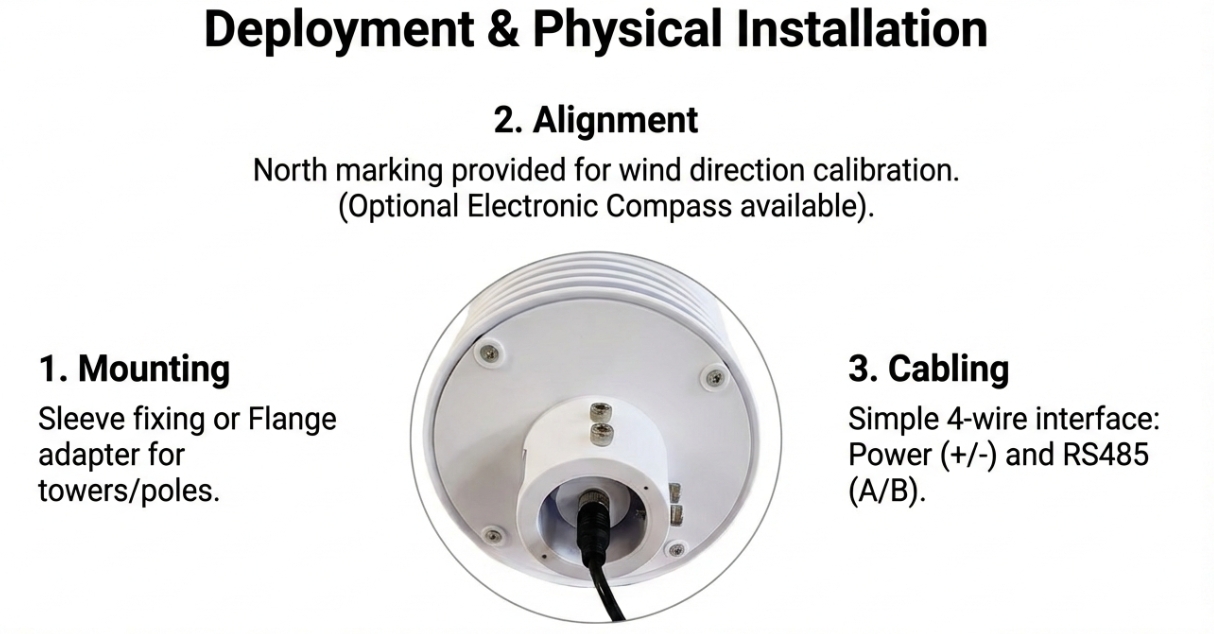

The Engineer’s Checklist: Avoiding Common Deployment “Pitfalls”

When specifying a B2B meteorological solution, verify the following architectural requirements:

- Environmental Testing Evidence: Ensure the sensors have been validated in wind tunnels and refrigerated chambers to guarantee accuracy across the full stated measuring range.

- High-Speed Processing: Confirm the use of 32-bit high-speed processing chips to ensure stable data acquisition and high anti-interference capabilities in electrically noisy industrial environments.

- Ingress Protection: A minimum IP65 rating is required for long-term outdoor deployment.

- Secure Mechanical Fixing: Look for flexible mounting options; the HD-CWSPR9IN1-01 supports both sleeve fixing and flange adapter fixing for secure attachment to various bracket types.

- Magnetic Declination Correction: For units equipped with the optional electronic compass, ensure the firmware supports magnetic declination correction (via register 0×0106) to align digital North with geographical North.

Conclusion & Strategic Call to Action (CTA)

The HD-CWSPR9IN1-01 addresses the high-maintenance costs and reliability gaps of traditional weather stations by consolidating high-precision, solid-state sensors into a single, resilient ASA housing. By eliminating mechanical wear and incorporating dual-stage precipitation verification, it provides the robust data foundation required for modern industrial automation.

Next Steps for Your Project:

- Download the Complete HD-CWSPR9IN1-01 Technical Specification Sheet (PDF) for detailed register mapping and wiring diagrams.

- Request a Custom IoT Solution Quote for Your Project to consult with our engineers on wireless integration and frequency customization.

For more information on specialized sensor arrays, visit our Product Pillar Page for a deep dive into ultrasonic sensor configurations.

Post time: Feb-06-2026