Abstract

Flow meters are critical instruments in industrial process control, energy measurement, and environmental monitoring. This paper compares the working principles, technical characteristics, and typical applications of electromagnetic flow meters, ultrasonic flow meters, and gas flow meters. Electromagnetic flow meters are suitable for conductive liquids, ultrasonic flow meters offer non-contact high-precision measurement, and gas flow meters provide diverse solutions for different gas media (e.g., natural gas, industrial gases). Research indicates that selecting the appropriate flow meter can significantly improve measurement accuracy (error < ±0.5%), reduce energy consumption (15%–30% savings), and optimize process control efficiency.

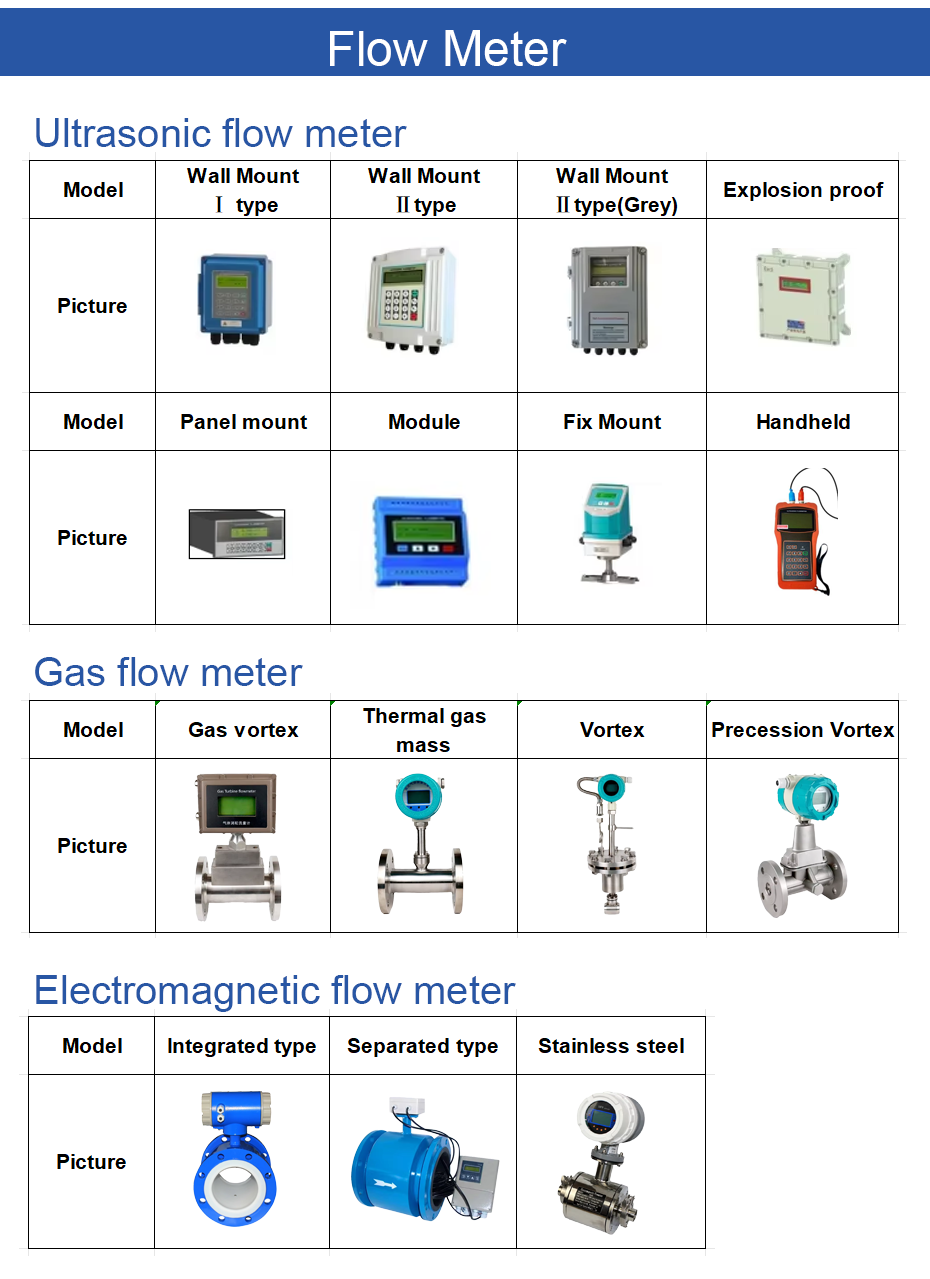

1. Electromagnetic Flow Meters

1.1 Working Principle

Based on Faraday’s Law of Electromagnetic Induction, conductive liquids flowing through a magnetic field generate a voltage proportional to flow velocity, which is detected by electrodes.

1.2 Technical Features

- Suitable Media: Conductive liquids (conductivity ≥5 μS/cm), such as water, acids, alkalis, and slurries.

- Advantages:

- No moving parts, wear-resistant, long service life

- Wide measurement range (0.1–15 m/s), negligible pressure loss

- High accuracy (±0.2%–±0.5%), bidirectional flow measurement

- Limitations:

- Not suitable for non-conductive fluids (e.g., oils, pure water)

- Susceptible to interference from bubbles or solid particles

1.3 Typical Applications

- Municipal Water/Wastewater: Large-diameter (DN300+) flow monitoring

- Chemical Industry: Corrosive liquid measurement (e.g., sulfuric acid, sodium hydroxide)

- Food/Pharmaceutical: Sanitary designs (e.g., CIP cleaning)

2. Ultrasonic Flow Meters

2.1 Working Principle

Measures flow velocity using transit-time difference (time-of-flight) or Doppler effect. Two main types:

- Clamp-on (Non-invasive): Easy installation

- Insertion: Suitable for large pipelines

2.2 Technical Features

- Suitable Media: Liquids and gases (specific models available), supports single/multi-phase flow

- Advantages:

- No pressure drop, ideal for high-viscosity fluids (e.g., crude oil)

- Wide measurement range (0.01–25 m/s), accuracy up to ±0.5%

- Can be installed online, low maintenance

- Limitations:

- Affected by pipe material (e.g., cast iron may attenuate signals) and fluid homogeneity

- High-precision measurements require stable flow (avoid turbulence)

2.3 Typical Applications

- Oil & Gas: Long-distance pipeline monitoring

- HVAC Systems: Energy measurement for chilled/heating water

- Environmental Monitoring: River/effluent flow measurement (portable models)

3. Gas Flow Meters

3.1 Main Types and Features

| Type | Principle | Suitable Gases | Advantages | Limitations |

|---|---|---|---|---|

| Thermal Mass | Heat dissipation | Clean gases (air, N₂) | Direct mass flow, no temp/pressure compensation | Unsuitable for humid/dusty gases |

| Vortex | Kármán vortex street | Steam, natural gas | High temp/pressure resistance | Low sensitivity at low flow |

| Turbine | Rotor rotation | Natural gas, LPG | High accuracy (±0.5%–±1%) | Requires bearing maintenance |

| Differential Pressure (Orifice) | Bernoulli’s principle | Industrial gases | Low cost, standardized | High permanent pressure loss (~30%) |

3.2 Typical Applications

- Energy Sector: Natural gas custody transfer

- Semiconductor Manufacturing: High-purity gas control (Ar, H₂)

- Emission Monitoring: Flue gas (SO₂, NOₓ) flow measurement

4. Comparison and Selection Guidelines

| Parameter | Electromagnetic | Ultrasonic | Gas (Thermal Example) |

|---|---|---|---|

| Suitable Media | Conductive liquids | Liquids/gases | Gases |

| Accuracy | ±0.2%–0.5% | ±0.5%–1% | ±1%–2% |

| Pressure Loss | None | None | Minimal |

| Installation | Full pipe, grounding | Requires straight runs | Avoid vibration |

| Cost | Medium-high | Medium-high | Low-medium |

Selection Criteria:

- Liquid Measurement: Electromagnetic for conductive fluids; ultrasonic for non-conductive/corrosive media.

- Gas Measurement: Thermal for clean gases; vortex for steam; turbine for custody transfer.

- Special Needs: Sanitary applications require dead-space-free designs; high-temperature media need heat-resistant materials.

5. Conclusions and Future Trends

- Electromagnetic flow meters dominate chemical/water industries, with future advancements in low-conductivity fluid measurement (e.g., ultrapure water).

- Ultrasonic flow meters are growing in smart water/energy management due to non-contact advantages.

- Gas flow meters are evolving toward multi-parameter integration (e.g., temp/pressure compensation + composition analysis) for higher accuracy.

- Complete set of servers and software wireless module, supports RS485 GPRS /4g/WIFI/LORA/LORAWANFor more flow meter information,

please contact Honde Technology Co., LTD.

Email: info@hondetech.com

Company website: www.hondetechco.com

Tel: +86-15210548582

Post time: Aug-13-2025