1. Executive Summary

To monitor deep well water quality effectively, an integrated 4G sensing system like the RD-ETTSP-01 combined with a Pneumatic Water Gauge is the industry standard. This 5-parameter solution simultaneously measures Electrical Conductivity (EC), TDS, Salinity, Temperature, and Liquid Level. By utilizing a corrosion-resistant PTFE electrode and a 4G/LoRaWAN gateway, operators can transmit real-time data from 10m+ depths to cloud servers. This architectural approach ensures stable performance in acidic or high-salinity industrial environments where traditional pressure transducers and standard electrodes typically fail.

2. Why PTFE Electrodes Outperform in Acidic Industrial Waste

Based on our 15 years of manufacturing industrial IoT nodes, we have found that standard electrodes degrade rapidly in deep-well environments containing high mineral content or industrial runoff. The RD-ETTSP-01 solves this through a PTFE (Polytetrafluoroethylene) electrode design, providing unmatched resistance to acids, alkalis, and high-salinity solutions.

Architectural Insight: The physical integration of the EC probe and the Pneumatic Water Gauge into a shared mounting bracket allows for a compact footprint, essential for 4-inch or 6-inch well casings. Unlike traditional pressure transducers that can foul in silty wells, the Pneumatic Gauge uses gas-medium sensing to provide a 0.2% accuracy level without direct liquid contact with sensitive internal diaphragms. Note: The gauge is suitable for any gas or liquid that does not corrode stainless steel.

3. Technical Specifications & Impedance Data

|

Parameter

|

Measurement Range

|

Accuracy

|

Resolution

|

|---|---|---|---|

|

EC (Conductivity)

|

0 ~ 2,000,000 µS/cm

|

±1% FS

|

10 µS/cm

|

|

TDS (Total Dissolved Solids)

|

0 ~ 100,000 ppm

|

±1% FS

|

10 ppm

|

|

Salinity

|

0 ~ 160 ppt

|

±1% FS

|

0.1 ppt

|

|

Temperature

|

0 ~ 60 °C

|

±0.5 °C

|

0.1 °C

|

|

Water Level (Pneumatic)

|

0 ~ 10 meters

|

0.2%

|

1 mm

|

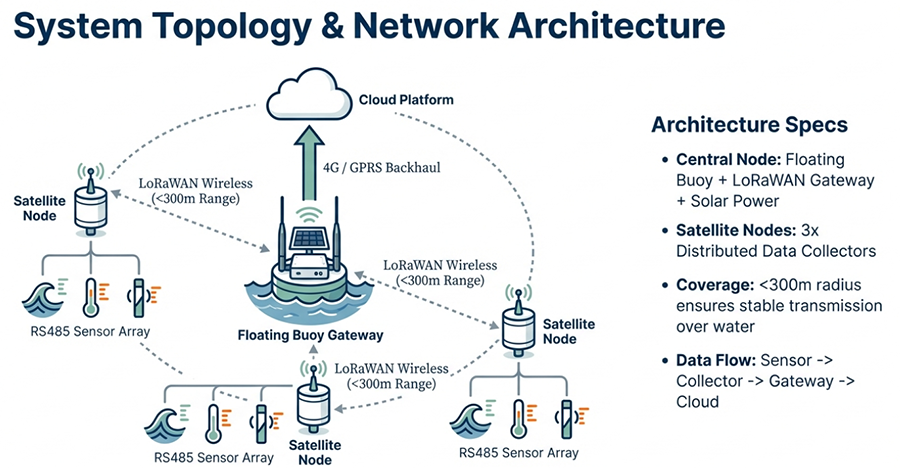

4. Optimizing Aquifer Management via 4G/LoRaWAN Ecosystem

5. Industry-Specific Application Scenarios

|

Environmental & Municipal

|

Industrial & Energy

|

Food & Agriculture

|

|---|---|---|

|

• Sewage Treatment Online Monitoring

|

• Thermal Power Cooling Water

|

• High-Density Aquaculture

|

|

• Tap Water Quality Distribution

|

• Metallurgy & Electroplating

|

• Fermentation Process Control

|

|

• Surface Water Salinity Tracking

|

• Chemical Industry Effluent

|

• Food Processing & Papermaking

|

|

• Textile Printing & Dyeing

|

• Acid/Alkali Recovery Systems

|

• Hydroponic Nutrient Leveling

|

6. Professional Installation: Avoiding the “Dead Cavity” Error

7. FAQ

Tags: Deep well water level EC sensor | Water EC & Level sensor with the 4G server and software

For more water sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-27-2026