On towering construction sites, tower cranes, as core heavy equipment, their safe operation directly affects the progress of the project, property safety and the lives of personnel. Among the numerous environmental factors that affect the safety of tower cranes, wind load is the largest and most unpredictable dynamic risk source. The mechanical wind speed and direction sensor specially designed by HONDE Company for the safety monitoring of tower cranes, with its outstanding reliability, shock resistance and precise measurement capabilities, has become an indispensable “high-altitude safety guard” for modern smart construction sites, providing the most direct and reliable data guarantee for the wind prevention and resistance of tower cranes.

I. Product Overview: A robust tool designed for extreme engineering environments

In response to the extreme working conditions of tower crane high-altitude operations (strong vibration, high wind speed, sun exposure, rain, and dust surrounding), HONDE’s mechanical sensors have been comprehensively strengthened:

Wind speed measurement: The three-cup wind cup assembly made of high-strength stainless steel or special engineering plastics, equipped with a heavy-duty bearing system, can withstand extreme wind load impacts of over 80m/s and gusts of more than 100m/s without damage, ensuring stable rotation and providing effective data even in storms.

Wind direction measurement: The tail wing-type wind vane adopts a streamlined low-inertia design, which can quickly respond to changes in wind direction. Its rotating mechanism is equipped with anti-jamming and anti-freezing designs, ensuring that it can freely point to the direction of the wind in any climate.

Core features: Passive mechanical induction and no complex electronic components give it an inherent advantage in high-altitude environments with frequent lightning and electromagnetic interference, with an extremely low failure rate and simple maintenance.

Ii. Core Applications in Tower Crane Safety Monitoring

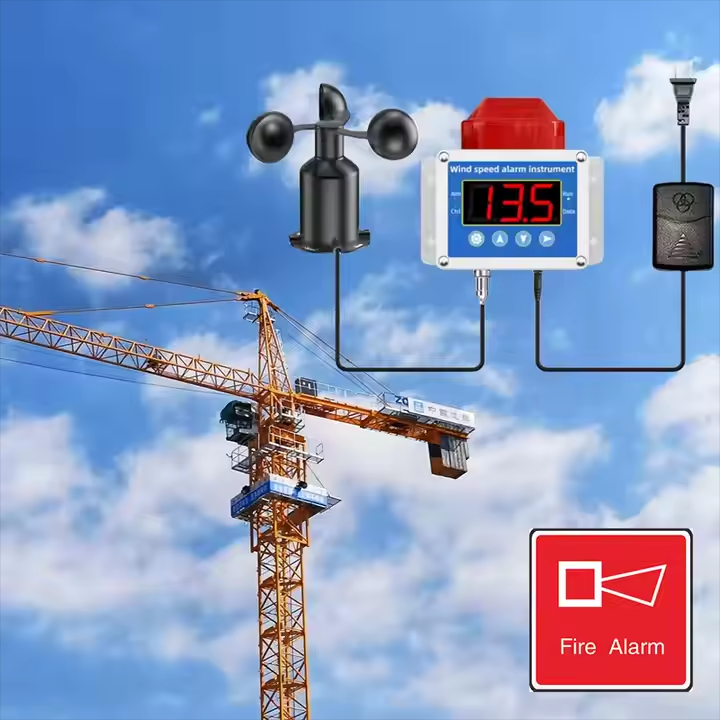

Real-time wind speed monitoring and hierarchical early warning

Application: Real-time monitoring of wind speed at the top of tower cranes (at the height of the boom) by sensors.

Hierarchical early warning and interlinked control

Warning wind speed (such as 20m/s) : The sound and light alarm is activated to alert drivers and ground personnel to pay attention to the wind conditions and operate with caution.

Limiting wind speed (such as the rated value, usually within the range of 20-30m/s) : The system issues a mandatory warning, requiring the suspension of hoisting operations, raising the hook to the highest position, and retracting the trolley to the root.

Non-working limit wind speed (such as above 40m/s) : The system can output signals to assist in controlling the tower crane to enter the free rotation state (release the rotation brake), enabling the boom to rotate with the wind like a wind vane, significantly reducing the windward area and wind load. This is a key protective measure to prevent the tower crane from overturning.

2. Wind direction monitoring and optimization of wind resistance strategies

Application: Real-time monitoring of wind direction.

Decision value

Guiding the tower crane to consciously adjust the boom to the minimum windward direction (usually the downwind direction) when it is not in operation, rather than simply freely rotating, can further reduce the wind load moment.

Help project managers take into account the prevailing wind direction of the day when arranging hoisting plans, and reduce the hoisting operations of large-volume and large windward surface components on the windy side.

3. Data recording and safety management traceability

Application: Continuously record wind speed and direction data, and it can be sent to the smart construction site cloud platform via a wireless transmission module (such as 4G).

Management value

Generate wind condition logs: Provide environmental background for each hoisting operation. In case of an accident, the wind condition data at that time can be traced.

Over-limit alarm record: Record all over-limit wind speed alarm events, enforce safety regulations, and prevent risky operations.

Provide a basis for structural health assessment: Long-term wind spectrum data can be used to evaluate the fatigue loads experienced by tower crane structures, providing scientific references for equipment maintenance and life assessment.

Iii. Core advantages of HONDE products: Specifically designed for tower crane operating conditions

Unparalleled mechanical reliability: In harsh environments such as vibration, salt spray, and alternating high and low temperatures, electronic sensors are prone to interference or damage, while the reliability of mechanical sensors is nearly “immortal”, ensuring that safety monitoring never goes offline.

Extremely high measurement accuracy and stability: The factory has undergone strict wind tunnel calibration, maintaining linear output throughout the full measurement range. There is no significant drift over long-term use, ensuring the accuracy of the warning threshold setting.

Strong environmental tolerance: With a protection level as high as IP67, key parts are made of stainless steel, and it features lightning protection design, making it unaffected by rain, cement dust and welding interference on construction sites.

Easy to install and maintain: Flange or clamp-type installation kits are provided for quick installation on the top of the tower crane or the standard section at the root of the boom. It only requires visual inspection on a daily basis and requires almost no maintenance.

Extensive system compatibility: Output standard signals (4-20mA, 0-10V or RS485), which can be seamlessly integrated into the tower crane’s own black box, third-party safety monitoring systems or smart construction site platforms.

Iv. Application Case: Safeguarding the Security Line of the “Skyline”

In a certain super high-rise building project, HONDE mechanical wind speed and direction sensors have been installed on the top of all four boom-type tower cranes and connected to the project’s smart construction site management system. During a strong typhoon warning:

Real-time monitoring: The sensor continuously transmits wind speed data. When the average wind speed is detected to consistently exceed 28m/s (the set stop operation wind speed), the system issues audible and visual alarms and lock instructions to all tower crane cabs and the command center.

Automatic execution plan: The driver lifts the hook to the top in accordance with the procedures and moves the control room to a safe position. The system, based on wind direction data, prompts and assists the driver to adjust the heavy boom to the downwind direction.

Safe passage through danger: During the passage of the typhoon, the maximum gusts can reach 45 meters per second. As the tower crane is already in the correct windproof state, the wind load has been reduced to the minimum. After the typhoon, the four tower cranes were inspected and found to have intact structures without any damage. They resumed production the next day.

The project safety director concluded: “At an altitude of 500 meters, we cannot confront the forces of nature, but we can rely on reliable technology to perceive in advance and respond intelligently.” The HONDE sensor is our “wind stabilizer” for high-altitude operations. Every reading it gives us more confidence.”

Conclusion

While the construction industry is evolving towards higher, faster and smarter goals, safety remains an unbreachable red line. Tower cranes, as the “lifeline” of construction sites, their wind resistance safety is of Paramount importance. HONDE mechanical wind speed and direction sensors, with their classic mechanical principles and ultimate industrial design, provide the most stable and reliable “nerve endings” for this “lifeline”. It transforms the intangible wind into quantifiable, early warning and executable safety instructions, building a key barrier for tower crane safety to shift from passive defense to active early warning and intelligent response. This is not only an upgrade of technical equipment, but also a manifestation of modern engineering safety management concepts – using definite technical means to deal with uncertain natural risks, and building the most solid high-altitude safety defense line for every city landmark that rises from the ground.

About HONDE: As an expert in industrial safety and special environment monitoring, HONDE is well aware of the strict requirements for the reliability of sensor devices in high-altitude and high-risk scenarios. We insist on applying the most mature and stable technologies to safety-critical fields with the highest process standards. In the field of tower crane safety monitoring, HONDE mechanical wind speed and direction sensors have become the designated safety standard equipment for many large-scale projects. We firmly believe that the highest reliability is the greatest safety.

For more wind speed sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Dec-18-2025