A Silent Agricultural Transformation

Inside a modern building in an advanced agricultural demonstration zone in Asia, an agricultural revolution is quietly unfolding. In a vertical farm, lettuce, spinach, and herbs grow in layers on nine-meter-tall planting towers, while tilapia swim leisurely in the water tanks below. Here, there is no soil, no traditional fertilization, yet a perfect symbiosis between fish and vegetables is achieved. The secret weapon behind this is a sophisticated water quality monitoring system—the Intelligent Aquaponic Monitoring Platform—as intricate as something from a sci-fi movie.

“Traditional aquaponics relies on experience and guesswork; we rely on data,” said a farm technical director, pointing to the numbers flashing on the control center’s large screen. “Behind each parameter is a set of sensors guarding the balance of this ecosystem 24/7.”

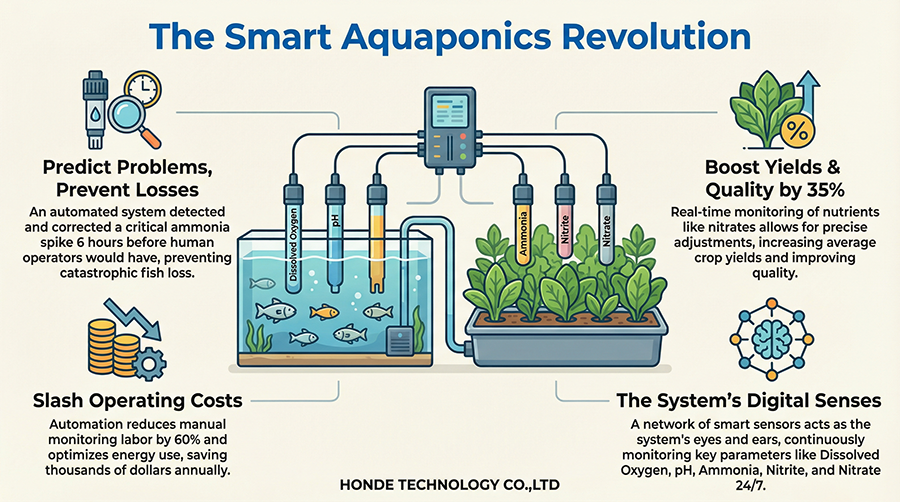

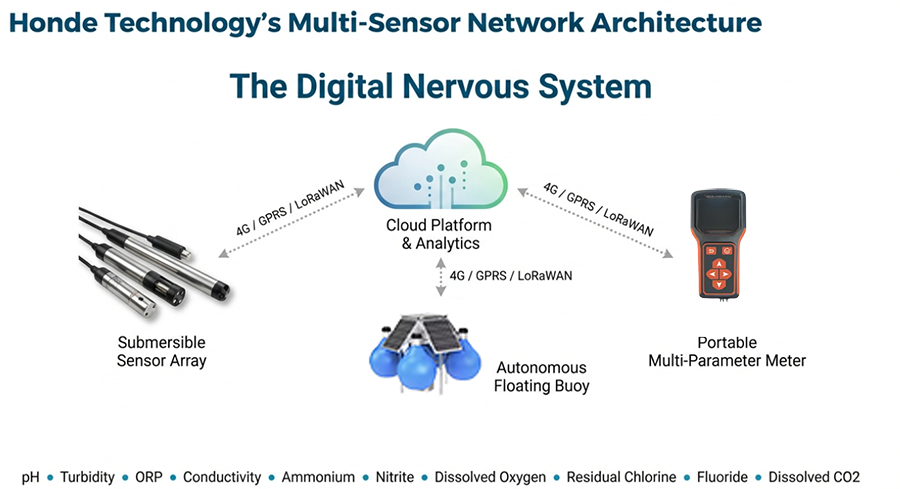

1: The System’s ‘Digital Senses’ – Multi-Sensor Network Architecture

Dissolved Oxygen Sensor: The Ecosystem’s ‘Pulse Monitor’

At the bottom of the aquaculture tanks, a set of optical dissolved oxygen sensors is continuously at work. Unlike traditional electrode-based sensors, these probes using fluorescence quenching technology require infrequent calibration and send data to the central control system every 30 seconds.

“Dissolved oxygen is our primary monitoring indicator,” explained a technical expert. “When the value drops below 5 mg/L, the system automatically initiates a tiered response: first increasing aeration, then reducing feeding if there’s no improvement within 15 minutes, while simultaneously sending a secondary alert to the administrator’s phone.”

pH and ORP Combination Sensor: The Water Environment’s ‘Acid-Base Balance Master’

The system employs an innovative pH-ORP (Oxidation-Reduction Potential) integrated sensor capable of simultaneously monitoring acidity/alkalinity and the water’s redox state. In traditional aquaponic systems, pH fluctuations often render trace elements like iron and phosphorus ineffective, while the ORP value directly reflects the water’s ‘self-cleaning capability.’

“We discovered a significant correlation between pH and ORP,” shared the technical team. “When the ORP value is between 250-350 mV, nitrifying bacteria activity is optimal. Even if the pH fluctuates slightly during this period, the system can self-regulate. This discovery helped us reduce pH adjuster usage by 30%.”

Ammonia-Nitrite-Nitrate Triple Monitoring: The Nitrogen Cycle’s ‘Full-Process Tracker’

The most innovative part of the system is the three-stage nitrogen compound monitoring module. By combining ultraviolet absorption and ion-selective electrode methods, it can simultaneously measure ammonia, nitrite, and nitrate concentrations, mapping the complete nitrogen transformation process in real-time.

“Traditional methods require testing the three parameters separately, while we achieve synchronous real-time monitoring,” a sensor engineer demonstrated with a data curve. “Look at the corresponding relationship between this declining ammonia curve and this rising nitrate curve—it clearly shows the efficiency of the nitrification process.”

Conductivity with Temperature Compensation Sensor: The Nutrient Delivery ‘Intelligent Dispatcher’

Considering the impact of temperature on conductivity measurement, the system uses a conductivity sensor with automatic temperature compensation to ensure accurate reflection of nutrient solution concentration at different water temperatures.

“The temperature difference between different heights of our planting tower can reach 3°C,” the technical lead said, pointing to the vertical farm model. “Without temperature compensation, the nutrient solution readings at the bottom and top would have significant errors, leading to uneven fertilization.”

2: Data-Driven Decisions – Practical Applications of Intelligent Response Mechanisms

Case 1: Preventive Ammonia Management

The system once detected an abnormal rise in ammonia concentration at 3 a.m. By comparing historical data, the system determined it was not normal post-feeding fluctuation but a filter abnormality. The automatic control system immediately initiated emergency protocols: increasing aeration by 50%, activating the backup biofilter, and reducing feeding volume. By the time management arrived in the morning, the system had already autonomously handled the potential failure, averting possible large-scale fish mortality.

“With traditional methods, such a problem would only be noticed in the morning when dead fish are seen,” the technical director reflected. “The sensor system gave us a 6-hour warning window.”

Case 2: Precision Nutrient Adjustment

Through conductivity sensor monitoring, the system detected signs of nutrient deficiency in lettuce at the top of the planting tower. Combining nitrate data and plant growth camera image analysis, the system automatically adjusted the nutrient solution formula, specifically increasing potassium and trace element supply.

“The results were surprising,” a farm plant scientist said. “Not only was the deficiency symptom resolved, but that batch of lettuce also yielded 22% more than expected, with higher vitamin C content.”

Case 3: Energy Efficiency Optimization

By analyzing dissolved oxygen data patterns, the system discovered that nighttime fish oxygen consumption was 30% lower than expected. Based on this finding, the team adjusted the aeration system operation strategy, reducing aeration intensity from midnight to 5 a.m., saving approximately 15,000 kWh of electricity annually from this measure alone.

3: Technological Breakthroughs – The Science Behind Sensor Innovation

Anti-Fouling Optical Sensor Design

The biggest challenge for sensors in aquatic environments is biofouling. The technical team collaborated with R&D institutions to develop a self-cleaning optical window design. The sensor surface uses a special hydrophobic nanoc coating and undergoes automatic ultrasonic cleaning every 8 hours, extending the sensor maintenance cycle from the traditional weekly to quarterly.

Edge Computing and Data Compression

Considering the farm’s network environment, the system adopted an edge computing architecture. Each sensor node has preliminary data processing capability, uploading only anomaly data and trend analysis results to the cloud, reducing data transmission volume by 90%.

“We process ‘valuable data,’ not ‘all data,’” explained an IT architect. “The sensor nodes determine what data is worth uploading and what can be processed locally.”

Multi-Sensor Data Fusion Algorithm

The system’s greatest technological breakthrough lies in its multi-parameter correlation analysis algorithm. Using machine learning models, the system can identify hidden relationships between different parameters.

“For example, we found that when dissolved oxygen and pH both slightly decline while conductivity remains stable, it usually indicates microbial community changes rather than simple hypoxia,” a data analyst explained, showing the algorithm interface. “This early warning capability is completely impossible with traditional single-parameter monitoring.”

4: Economic Benefits and Scalability Analysis

Return on Investment Data

- Initial sensor system investment: approximately $80,000–100,000 USD

- Annual benefits:

- Fish mortality reduction: from 5% to 0.8%, resulting in significant annual savings

- Feed conversion ratio improvement: from 1.5 to 1.8, yielding substantial annual feed cost savings

- Vegetable yield increase: average 35% boost, generating considerable annual added value

- Labor cost reduction: monitoring labor decreased by 60%, producing notable annual savings

- Investment payback period: 12–18 months

Modular Design Supports Flexible Expansion

The system employs a modular design, allowing small farms to start with a basic kit (dissolved oxygen + pH + temperature) and gradually add ammonia monitoring, multi-zone monitoring, and other modules. Currently, this technological solution has been deployed in dozens of farms across multiple countries, suitable for everything from small household systems to large commercial farms.

5: Industry Impact and Future Outlook

Standards Development Push

Based on the practical experience of advanced farms, agricultural departments in multiple countries are developing smart aquaponic system industry standards, with sensor accuracy, sampling frequency, and response time becoming core indicators.

“Reliable sensor data is the foundation of precision agriculture,” said an industry expert. “Standardization will drive technological progress across the entire industry.”

Future Development Directions

- Low-Cost Sensor Development: Research and development of low-cost sensors based on new materials, aiming to reduce core sensor costs by 60–70%.

- AI Prediction Models: Integrating meteorological data, market data, and growth models, the future system will not only monitor current conditions but also predict water quality changes and yield fluctuations days in advance.

- Full-Chain Traceability Integration: Each batch of agricultural products will have a complete ‘growth environment record.’ Consumers can scan a QR code to view key environmental data from the entire growth process.

“Imagine when purchasing agricultural products, being able to see key environmental parameter records from their growth process,” envisioned the technical lead. “This will set a new standard for food safety and transparency.”

6.Conclusion: From Sensors to a Sustainable Future

In the control center of the modern vertical farm, hundreds of data points flash on the large screen in real-time, mapping the complete lifecycle of a micro-ecosystem. Here, there are no approximations or estimates of traditional agriculture, only scientifically managed precision to two decimal places.“Each sensor is the system’s eyes and ears,” summarized a technical expert. “What truly transforms agriculture isn’t the sensors themselves, but our ability to learn to listen to the stories these data tell.”As global population grows and climate change pressures increase, this data-driven precision agriculture model may well be key to future food security. In the circulating waters of aquaponics, sensors are quietly writing a new chapter for agriculture—a smarter, more efficient, more sustainable future.Data Sources: International advanced farm technical reports, agricultural research institution public data, International Aquacultural Engineering Society proceedings.Technical Partners: Multiple university environmental research institutes, sensor technology companies, agricultural research institutions.Industry Certifications: International Good Agricultural Practices certification, testing laboratory certification

Hashtags:

#IoT#aquaponic monitoring system #Aquaponics #Water Quality Monitoring #Sustainable Agriculture #Digital Agriculture Water Quality Sensor

For more water sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-29-2026