1.0 Introduction: Your Direct Answer to Remote Environmental Monitoring

Creating a reliable wireless environmental monitoring system involves integrating a modular ultrasonic weather station and soil sensors with a LoRa collector for local data consolidation and a 4G MQTT gateway for real-time remote transmission. This all-in-one approach provides a robust, maintenance-free solution for capturing critical weather and soil data. This engineering guide details the system components, a straightforward four-step setup process, and the key features that ensure data accuracy and operational reliability in demanding field conditions.

2.0 Why an Ultrasonic All-in-One Sensor is the Core of a Modern System

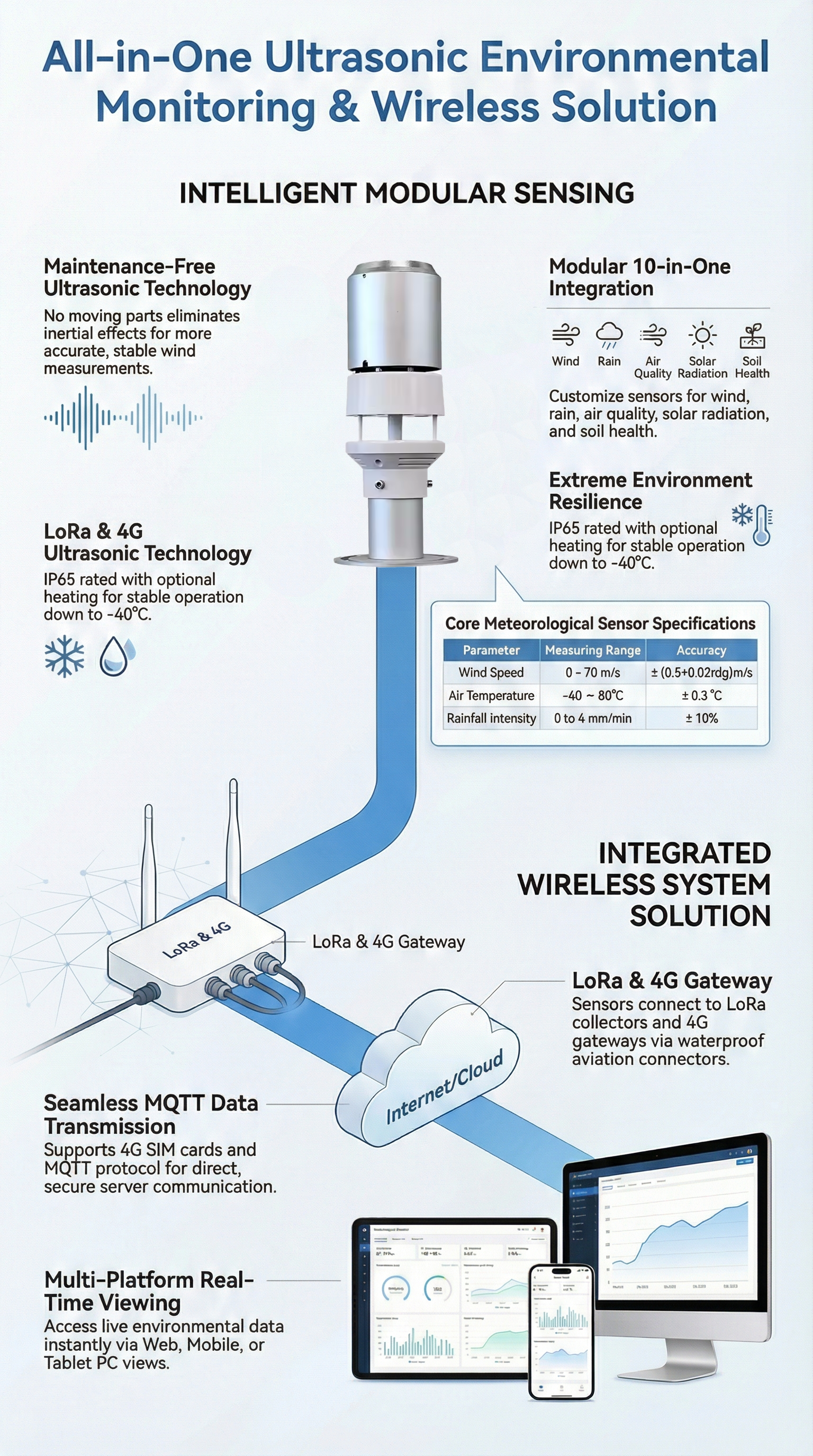

The core of this system is an ultrasonic environmental monitor. By using the time difference measurement principle, it has no rotating parts, which virtually eliminates the inertial effects that can delay and distort readings from traditional mechanical anemometers. This design allows for faster and more accurate measurements of environmental factors like wind speed and direction. The lack of moving components also results in a maintenance-free sensor, which is critical for long-term, remote deployments.

3.0 The Complete System Architecture: From Sensor to Screen

The system is designed for simplicity and reliability, consisting of four key stages: data collection at the sensor level, local data consolidation, wireless transmission to the cloud, and finally, data visualization on your chosen device.

3.1 Step 1: The Sensors – Your Data Collection Points

The system’s flexibility begins with its modular sensor options.

- The Ultrasonic Environmental Monitor: This is the primary weather station. It is a highly integrated, modular unit constructed from durable ABS engineering plastics. Users can customize the sensor by selecting the specific environmental monitoring elements they need, with the ability to integrate up to 10 different factors. Standard configurations can measure wind speed, wind direction, air temperature, and humidity, but the platform’s modularity allows for significant customization. For example, units can be built to include solar radiation sensors, PM10 particulate monitors, and optical rainfall sensors, all integrated into a single housing with one data output.

- The Soil Monitoring Sensors: To create a complete environmental picture, the system supports dedicated soil sensors. These are available as “two in one” units that measure both soil moisture and soil temperature.

3.2 Step 2: The LoRa Collector – Consolidating Local Sensor Data

The LoRa collector serves as the local data hub, integrating data from up to three separate sensors. The connection process is simple: connect the sensors to any of the three ports using the provided waterproof connectors, connect the power supply (red wire for positive, black for negative; the yellow and green wires are typically unused), and install the LoRa antenna. The collector will then begin gathering data from all connected sensors.

3.3 Step 3: The LoRa/4G Gateway – Transmitting Data via MQTT

The LoRa gateway receives the consolidated data from the LoRa collector and transmits it over a 4G cellular network using the lightweight MQTT protocol, which is ideal for IoT applications. The gateway is designed for rapid deployment, with pre-configured server information to streamline setup:

- Insert your 4G SIM card into the card slot.

- Connect the two antennas (one for LoRa reception, one for 4G transmission).

- Connect the 12-watt DC power adapter.

- Verify APN Settings: Ensure the APN (Access Point Name) of your 4G SIM card matches the pre-configured settings in the gateway to guarantee a successful network connection.

Once powered on, the gateway automatically connects to the network and begins transmitting data.

3.4 Step 4: The Platform – Real-Time Data Visualization

Once the system is fully configured and online, the environmental data can be viewed in real-time on multiple platforms. The system supports a Web view for desktop analysis, a Mobile view for on-the-go monitoring, and a Tablet PC view.

4.0 Engineered for Reliability: Key Features and Durability Testing

The system is engineered for long-term, reliable operation in harsh environmental conditions, validated by a series of rigorous tests.

- Modular & Customizable Design: The system is highly modular, allowing for the integration of up to 10 environmental factors in a single unit. This de-risks projects by allowing for post-deployment sensor upgrades. Optional functions include GPS/Beidou positioning and an electronic compass for advanced tracking and orientation needs.

- Advanced Ultrasonic Technology: The use of the more expensive and accurate 200Khz ultrasonic probe ensures that wind speed and direction measurements are more accurate and stable compared to standard alternatives.

- Extreme Temperature Performance: An optional high-efficiency heating function is available for deployment in ice, snow, and freezing rain. Our lab tests confirm that after a -40°C low-temperature test with the heating function activated, the heating function prevented the probe from freezing, ensuring continuous, normal operation.

- Salt Spray Corrosion Resistance: The probe is fully sealed and has passed the national standard salt spray test with good results, making it ideal for deployment in corrosive coastal and port environments. Our internal testing procedure involves running the product in a salt spray machine for 168 hours to verify normal communication and check for any signs of rust.

- Rigorous Environmental Hardening: The product has undergone a comprehensive suite of environmental tests to ensure its durability, including high and low temperature, waterproof (IP65 protection), salt spray, and sand and dust tests.

5.0 Technical Deep Dive: Specifications for Precision and Integration

The following specifications detail the performance and physical characteristics of the ultrasonic environmental monitor, providing the necessary data for system integration and environmental suitability assessments.

5.1 Main Technical Parameters

| Parameter | Specification |

| Electrical Parameters | |

| Operating Voltage | DC 9V -30V or 5V |

| Product Power Consumption | 0.4W (10.5W when heating) |

| Signal Output Method | RS485 or 4G wireless signal output |

| Mechanical Parameters | |

| Material | ABS engineering plastics |

| Working Environment | -40℃ ~ +60℃, 0~100%RH |

| Protection Level | IP65 |

| Outlet Method | Aviation socket, sensor line 3 meters |

| Reference Weight | Approx. 0.5KG (2 parameters); 1KG (5 parameters or multiple parameters ) |

5.2 Optional Sensor Specifications

| Optional Environmental Factor | Range | Accuracy | Resolution |

| Wind Speed | 0-70m/s | ±(0.5+0.02rdg)m/s | 0.01m/s |

| Wind Direction | 0 to 360° | ±3° | 1° |

| Atmospheric Temperature | -40~80℃ | ±0.3℃ | 0.1℃ |

| Atmospheric Humidity | 0~100%RH | ±5%RH | 0.1%RH |

| Atmospheric Pressure | 300~1100hPa | ±1hPa (25°C) | 0.1hPa |

| Rainfall Intensity | 0 to 4mm/min | ±10% | 0.03mm/min |

| PM2.5/10 | 0~1000μg/m³ | ≤100ug/m³: ±10ug/m³; >100ug/m³: ±10% | 1μg/m³ |

| Soil Moisture | 0~60% | ±3% (0-3.5%); ±5% (3.5-60%) | 0.1% |

| Soil Temperature | -40~80℃ | ±0.5℃ | 0.1℃ |

6.0 Conclusion: A Flexible and Robust Solution

Ultimately, this wireless environmental monitoring system represents a modular, reliable, and rapidly deployable solution for a wide range of professional applications. By combining a durable, maintenance-free ultrasonic weather station with specialized soil sensors and a simple wireless architecture, it delivers real-time, actionable data. The system is highly suitable for demanding fields such as smart agriculture, meteorology, forestry, and environmental protection.

7.0 Get a Custom Solution for Your Project

Ready to build a monitoring system tailored to your specific needs? Contact our team to get a custom quote for your project.

Tags: weather sensor | Wireless Solutions

For more weather station information, please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-30-2026