2026 Heat Safety Monitoring Guide

In extreme heat environments, relying solely on air temperature (dry-bulb temperature) to assess worker health risks is extremely dangerous. As global temperatures rise, the WBGT (Wet Bulb Globe Temperature) index has become the internationally recognized standard for heat stroke prevention in construction, smelting, and military training.

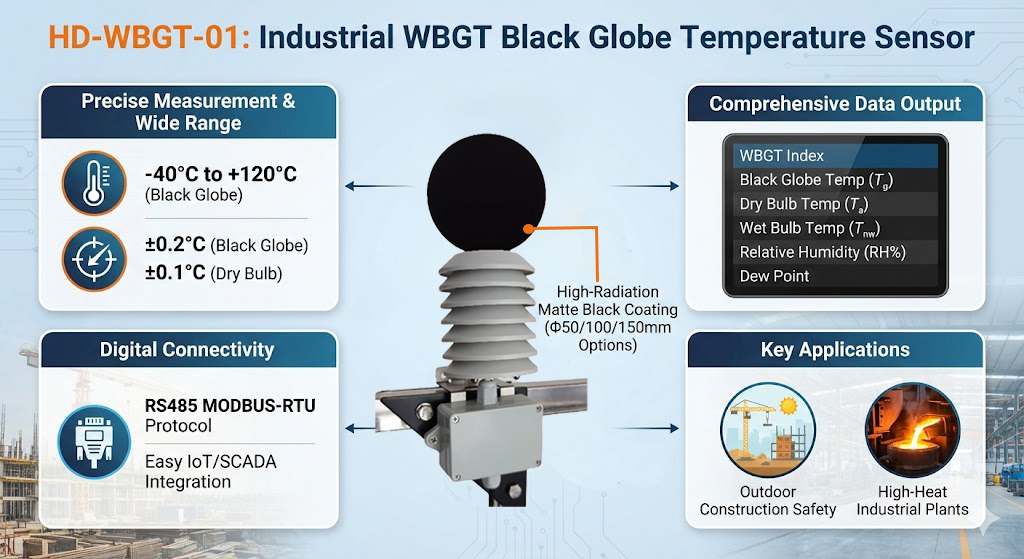

Based on the technical specifications of the HD-WBGT-01 sensor, this guide provides an in-depth analysis of how black globe temperature monitoring can enhance workplace safety.

What is Black Globe Temperature?

Why is it Crucial?

Black Globe Temperature, also known as “real-feel temperature,” represents the actual thermal sensation experienced by a person or object subject to the combined effects of radiant and convective heat in a radiant environment.

- Dry-Bulb Temperature: Indicates only the degree of air coldness or hotness, typically measured in a louvered box to avoid direct sunlight.

- Black Globe Temperature: Simulates the heat absorbed from direct sunlight, ground reflection, and industrial radiation.

For outdoor workers, the black globe temperature is often significantly higher than standard meteorological forecasts, making it the core metric for deciding work stoppages or heat-related safety protocols.

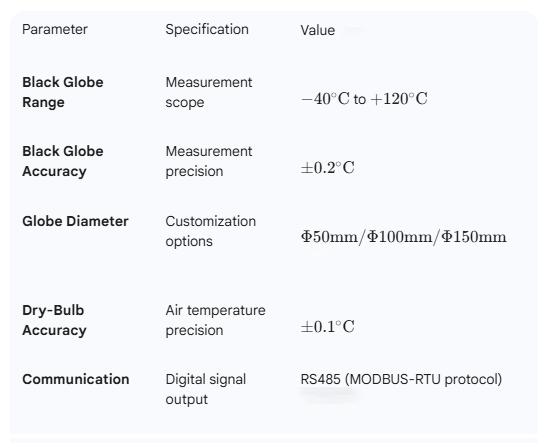

Core Technical Specifications: HD-WBGT-01 Sensor

Precision and response time are the most critical factors for industrial-grade equipment.

1. Structured Technical Data

2. Why Choose Matte Black Body Coating?The HD-WBGT-01 uses a metal sphere treated with an industrial-grade matte black coating featuring a high radiation heat absorption rate. This design ensures optimal heat conduction and absorption of light and thermal radiation, providing the most accurate “real-feel” data.

Application Scenarios and System Integration

As a comprehensive industrial monitoring solution, the WBGT sensor is designed for easy integration:

- Outdoor Construction Sites: Connect the sensor to a 4G MQTT system for remote monitoring; when WBGT values reach hazardous levels, a linked LED sound and light alarm can alert workers to take breaks.

- High-Heat Industrial Plants: The sensor can be fixed to walls, brackets, or equipment boxes to monitor radiant heat in environments like glass or steel manufacturing.

Expert Maintenance Tips: Ensuring Long-Term Accuracy

To maintain high data precision, follow these essential maintenance guidelines:

1. Keep the Surface Clean: Dust or debris on the black globe will lower the heat absorption rate and lead to inaccurate measurements.

2. Avoid Chemical Cleaners: Clean the globe only with a soft brush or air blower. Using alcohol or acid-base liquids can cause irreversible damage to the coating.

3. Prevent Physical Impact: The sensor contains high-precision temperature-measuring elements; ensure anti-knock measures are taken during storage and installation.

Conclusion: The Future of Digital Heat Safety Management

Modern safety management requires moving beyond “intuition” regarding heat risks. By deploying high-precision sensors like the HD-WBGT-01, enterprises can establish a traceable, digital thermal safety system.

Need the full RS485 communication protocol or a custom quote?

[Click here to download the User Manual (PDF)] or [Contact our Technical Engineers]

For more smart sensor information, please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-14-2026