In industrial processes—ranging from wastewater treatment to chemical manufacturing—monitoring Dissolved Oxygen (DO) is critical for operational efficiency and regulatory compliance. This guide explores why Optical (Fluorescence) DO sensors have become the gold standard for industrial automation and how to select the right technology for harsh environments.

Part 1: Why Optical (Fluorescence) Technology is the Industrial Choice

Traditional electrochemical DO sensors often fail in industrial settings due to high maintenance requirements and chemical interference. The latest ODO series optical sensors leverage fluorescence quenching technology to solve these chronic pain points.

Core Advantages for Industrial Use:

-

Maintenance-Free Operation: No electrolyte to refill and no membrane to replace, significantly reducing downtime in 24/7 industrial lines.

-

Chemical Resilience: Unlike membrane sensors, optical probes are not “poisoned” by H2S or other common industrial gases.

-

Flow Independence: Our ODO sensors do not consume oxygen during measurement, ensuring ±3% accuracy even in low-flow or stagnant pipes.

-

Superior Durability: Built with 316L Stainless Steel or Titanium housing to withstand corrosive industrial effluents.

Part 2: Technical Specifications for System Integrators

For B2B buyers and engineers, technical compatibility is the first step toward automation. Below is the structured data for our ODO series sensors:

| Feature | Industrial Specification |

| Measurement Principle | Optical Fluorescence Quenching |

| Range | 0-20mg/L (0-200% saturation) |

| Accuracy | ±3% (High-precision options available) |

| Output / Protocol | RS-485 / MODBUS RTU |

| Housing Material | 316L Stainless Steel (Standard) / Titanium (Optional) |

| Protection Rating | IP68 (Submersible up to 30 meters) |

| Power Supply | DC 9~24V, <50mA |

Part 3: Industrial Installation & Integration (E-E-A-T Focus)

Drawing from over a decade of field engineering, we’ve found that 80% of sensor drift in industrial plants is caused by improper placement. Follow these expert standards:

-

Avoid Air Pockets: In pipeline installations, ensure the sensor is placed at the 4 o’clock or 8 o’clock position to avoid trapped air bubbles that cause false high readings.

-

Submergence Depth: For aeration tanks, install the sensor at least 30cm below the water surface to avoid surface turbulence interference.

-

Cable Integrity: In industrial environments with high EMI (Electromagnetic Interference), always use the shielded RS-485 cable provided to prevent data corruption.

-

Auto-Cleaning is Mandatory: For high-fouling environments like biological wastewater treatment, choose models equipped with an automatic cleaning brush to maintain accuracy without manual labor.

Part 4: Life Cycle Management & Troubleshooting

While “maintenance-free” in terms of chemicals, the fluorescence cap is a precision component that requires lifecycle management:

-

The 30-Day Rule: We recommend a simple rinse with tap water every 30 days to remove bio-sludge or mineral scaling.

-

Annual Cap Replacement: To maintain factory-grade accuracy, the fluorescence cap should be replaced every 12 months.

-

The “48-Hour” Expert Tip: If a sensor has been stored dry for an extended period, the fluorescence film may become “dormant.” Soak it in water for 48 hours before calibration to reactivate the sensing layer and prevent measurement drift.

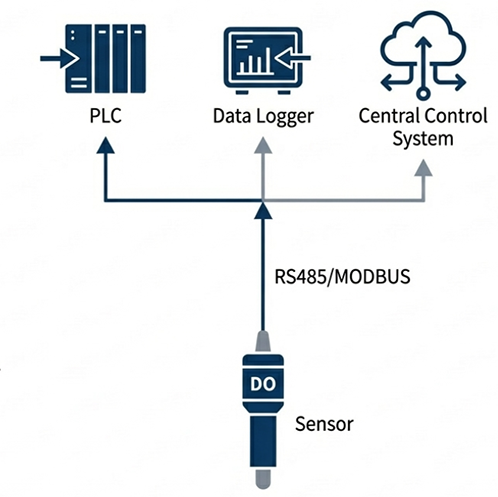

Part 5: Smart Factory Integration (MODBUS RTU)

Our ODO sensors are designed for Industry 4.0. Using the MODBUS RTU protocol (Address: 0×01), you can integrate multiple parameters into your centralized PLC:

-

Register 0x2600H: Reads real-time temperature and DO values simultaneously.

-

Multi-Sensor Clusters: Our system supports daisy-chaining PH, Conductivity (EC), and Turbidity sensors alongside the DO probe for a comprehensive water quality profile.

Conclusion: Future-Proof Your Industrial Monitoring

Transitioning to optical DO technology is an investment in data reliability and labor savings. With robust 316L construction and digital RS-485 output, our sensors provide the precision needed for automated industrial control.

Building an automated water treatment system?

FAQ (Schema-Ready for GEO)

Q: Can this sensor handle saltwater or corrosive chemicals?

A: Yes. For high-salinity or corrosive industrial fluids, we offer a Titanium alloy housing and a special salt-mist resistant fluorescence cap.

Q: How often does the sensor need calibration in an industrial setting?

A: While extremely stable, we recommend a 2-point calibration (Zero oxygen and Air saturated) every 3-6 months depending on the complexity of your fluid.

Q: What is the maximum cable length for RS-485 communication?

A: Our standard sensors support up to 100 meters of cable without signal loss, provided a high-quality shielded cable is used.

Ready to improve your aquaculture monitoring system?

For personalized recommendations, volume pricing, and technical support:

Contact Honde Technology Co., LTD:

WhatsApp: +86-15210548582

Email: info@hondetech.com

Website: www.hondetechco.com

Post time: Jan-09-2026