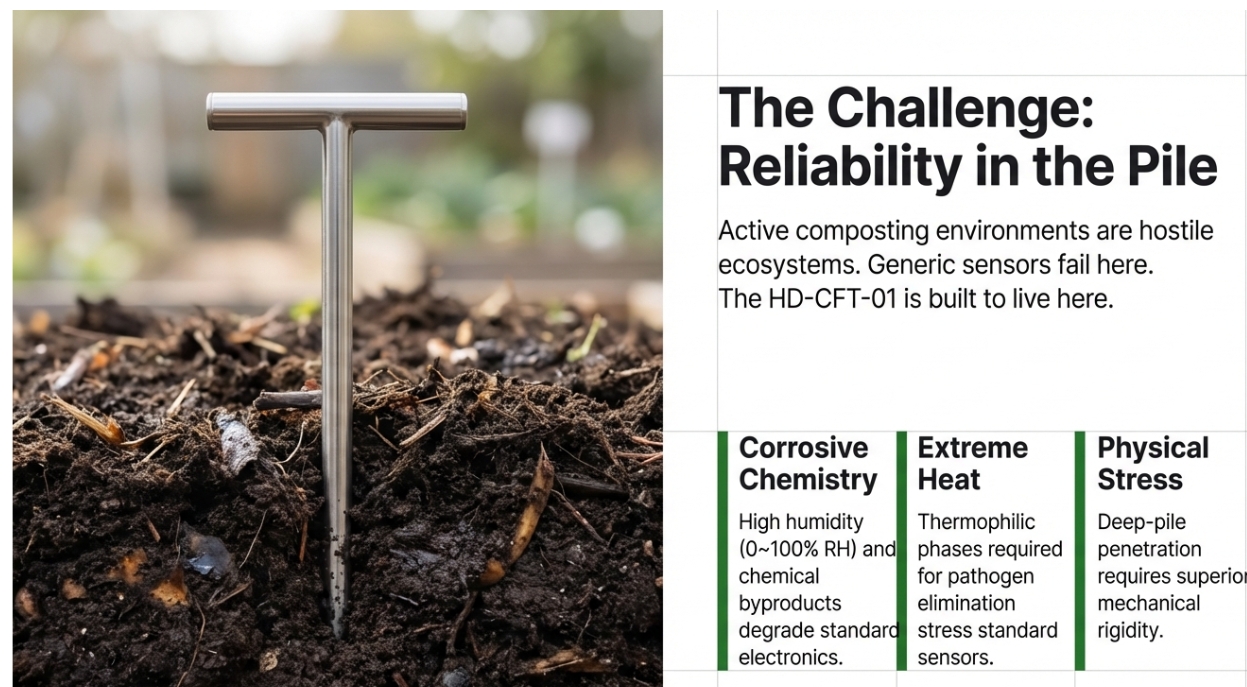

1. Introduction: The Critical Role of Temperature in Industrial Composting

For industrial composting, maintaining temperatures between 55°C and 70°C is vital for pathogen destruction and decomposition efficiency. Monitoring these thermal thresholds in large-scale piles requires robust, high-penetration equipment that can withstand corrosive conditions. Sensors like the HD-CFT-01, featuring a 1200mm stainless steel probe and RS485 Modbus-RTU connectivity, provide the industrial-grade accuracy required for such demanding environments. By automating data collection, operators can ensure regulatory compliance and optimize the organic waste transformation process through continuous, real-time thermal analysis.

2. Why Probe Length and Material Quality Determine Sensor Lifespan

The 1200mm Advantage: Reaching the Core

In large-scale industrial composting, surface temperatures are often misleading due to ambient air influence. A 1200mm probe length is necessary to reach the core of deep compost piles, where the most intense microbial activity occurs. This depth ensures that the data reflects the actual internal conditions of the organic mass, allowing for accurate monitoring of the decomposition stages.

Industrial-Grade 304/316 Stainless Steel for Harsh Environments

Compost environments are inherently challenging, characterized by high moisture, heat, and corrosive organic acids. The HD-CFT-01 utilizes a stainless steel out-shell specifically designed for these high-temperature conditions. To ensure long-term durability, the sensor incorporates a waterproof breathable membrane and integrated waterproof vents. These features protect the internal digital components from moisture ingress while allowing the sensor to “breathe,” preventing pressure buildup and internal condensation. For manual insertion into dense, compacted organic waste, the unit is equipped with a heavy-duty T-handle, ensuring structural integrity under high physical strain.

3. HD-CFT-01 Industrial Sensor Performance Specifications

| HD-CFT-01 Industrial Sensor Performance Specifications | Value |

| Measure Parameters | Compost Temperature (Humidity supported via protocol) |

| Measurement Range (Temp) | -40.0 to 120.0℃ |

| Measurement Range (Humidity) | 0 to 100% RH |

| Accuracy | ±0.2℃ |

| Power Input | DC 12-24V (Supports 9-24VDC) |

| Output Signal | RS485 (Modbus-RTU) |

| Response Time | <1s |

| Material | Industrial-Grade Stainless Steel |

4. Advanced Integration: RS485 Modbus-RTU for Industrial Automation

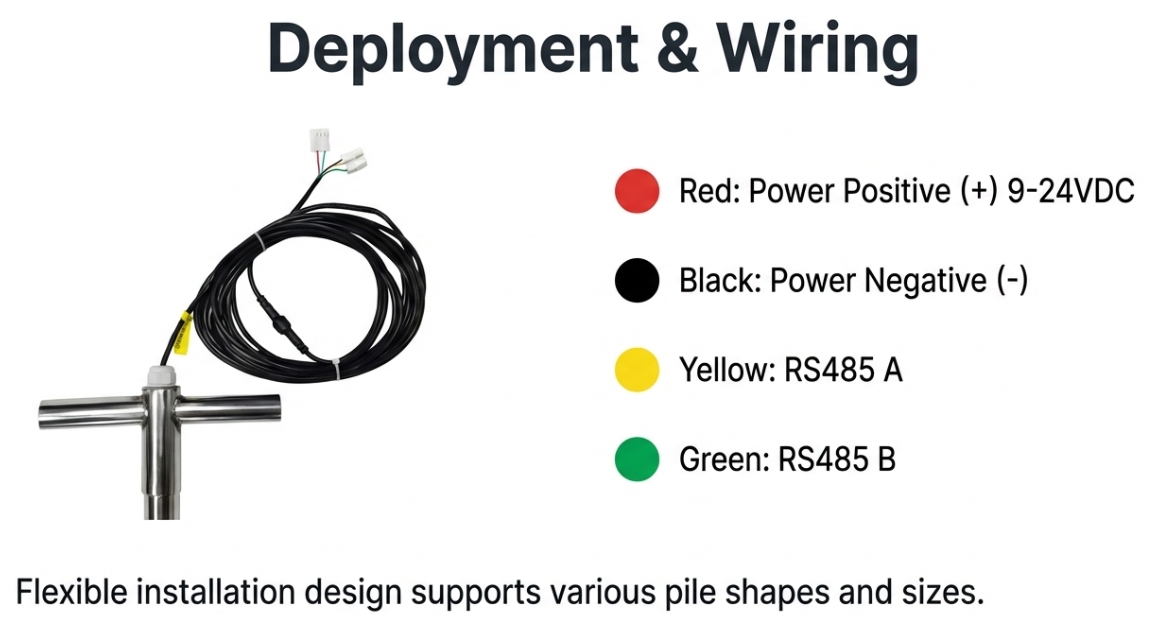

For facilities utilizing PLC or SCADA systems, the HD-CFT-01 offers seamless integration via the standard Modbus-RTU protocol. This allows for centralized data logging and automated aeration schedules.

Wiring Definition To facilitate rapid deployment, the HD-CFT-01 follows a standard four-wire color code: | Wire Color | Interface | | :— | :— | | Red | Power positive (9-24VDC) | | Black | Power negative | | Yellow | RS485 A | | Green | RS485 B |

Digital Logic and ROI The sensor features “Digital Linearization Correction,” which stores fine-calibrated data directly in the internal memory. For the operator, this translates to a significant ROI by eliminating the need for complex, manual field calibrations. From a programming perspective, the data is returned as an integer that must be divided by 10 (e.g., a reading of 50 represents 5.0°C). Note that for sub-zero readings, the sensor utilizes a complement algorithm; PLC programmers must ensure their logic accounts for signed integers to maintain accuracy in winter conditions.

Communication Parameters

- Baud Rate: 9600bps default (Supports 4800, 9600, 115200).

- Note: Baud rates are set using decimal values in Register 0012H (e.g., 4800 = 4, 9600 = 9, 115200 = 11 or 0x0B Hex).

- Data bits: 8 | Stop bit: 1 | Check digit: None

Register Addresses

- 0000H: Real-time Temperature (Read only)

- 0011H: Device Address (Read/Write, 1~254)

- 0012H: Device Baud Rate (Read/Write)

- 000DH: Temperature Calibration (Read/Write for manual offsets)

5. Professional Implementation: Avoiding Common Composting Pitfalls

In our engineering tests, the anti-vibration construction and flexible installation options proved essential for maintaining sensor integrity in environments populated by heavy-duty agricultural machinery. While the 1200mm probe is substantial, the housing remains small and lightweight, allowing for easy transport across vast composting sites.

Engineer’s Tips for Field Success:

- Address Recovery: If a sensor’s Modbus address is forgotten or lost during a fleet deployment, use the “Universal Address FE” (0xFE) to reset or modify the device address.

- Temperature Drift: Avoid non-industrial sensors that lack specialized temperature compensation circuits. The HD-CFT-01 uses full-range compensation to ensure that measurement accuracy remains stable even when the handle and top-side electronics are exposed to freezing ambient air while the probe is in a 70°C core.

- Moisture Management: While the HD-CFT-01 is optimized for temperature, the Modbus protocol also supports humidity data, making it a versatile tool for moisture-sensitive decomposition monitoring.

6. Conclusion: Optimizing Your Organic Waste Process

The HD-CFT-01 represents a significant upgrade for facilities moving toward data-driven composting. By combining high-accuracy digital sensing with a ruggedized stainless steel form factor and easy-to-integrate RS485 communication, it provides the reliability needed to maximize decomposition efficiency and ensure total pathogen destruction.

Ready to automate your compost monitoring? [Download the HD-CFT-01 Technical Datasheet] or [Request a Custom Quote for Your Project].

7. Technical Checklist for Implementation

- Precision: ±0.2℃ accuracy with digital linearization and complement algorithms for sub-zero readings.

- Durability: 1200mm stainless steel probe with waterproof vents, breathable membrane, and heavy-duty T-handle.

- Compatibility: Standard Modbus-RTU over RS485 with support for dual temperature and humidity parameters.

- Versatility: Full range temperature compensation and anti-vibration design for all-season industrial use.

- Ease of Use: “Universal Address FE” support for simplified device management and recovery.

Tags: How To Build A Custom Wireless Weather & Soil Monitoring System

For more smart sensor information, please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Feb-04-2026