1. Introduction:

Inside a flagship facility at the Asian Advanced Agricultural Demonstration Zone, a quiet revolution is redefining food security. Within this modern vertical farm, nine-meter-high planting towers host layers of lettuce and herbs, while tilapia tanks below drive a closed-loop nutrient cycle. This is a soil-less, high-density ecosystem functioning in perfect symbiosis.

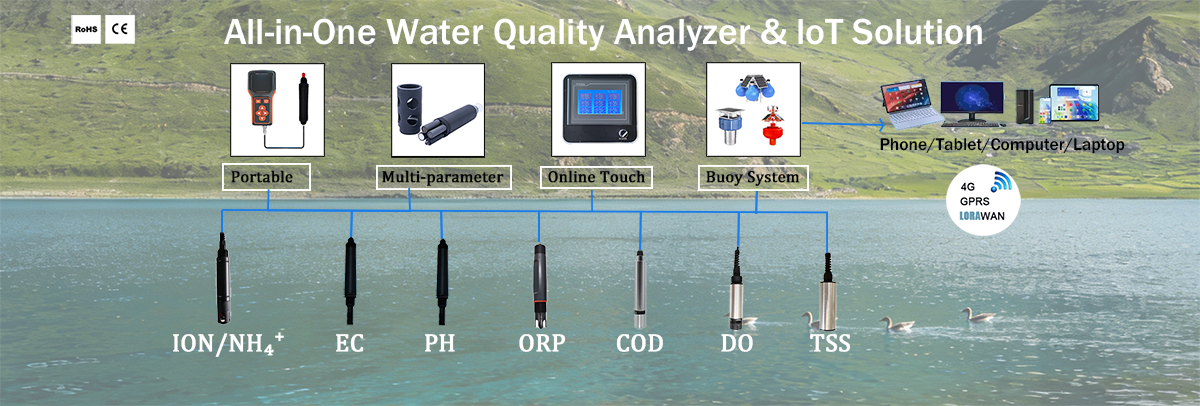

As a Solutions Architect, the true marvel isn’t just the height of the towers, but the “Digital Sense” network powering the facility. We have transitioned from “experience-based farming”—reliant on intuition and manual testing—to “data-driven precision.” By deploying a sophisticated multi-sensor LoRaWAN fabric, we maintain a delicate ecological balance 24/7, ensuring that every biological shift is met with an automated, calculated response.

2.The Multi-Sensor Network

Maintaining a high-density aquaponic system requires monitoring parameters that are often invisible until a catastrophic failure occurs. Our network utilizes a suite of industrial-grade sensors designed to eliminate data silos.

- Dissolved Oxygen (DO): Utilizing fluorescence quenching technology, these sensors require no frequent calibration or membrane replacement. They monitor the ecosystem’s “pulse” every 30 seconds. If levels drop below the critical 5mg/L threshold, the system triggers a tiered response: increasing aeration intensity, reducing feed protocols, and alerting onsite managers via a secondary alarm.

- pH & ORP Combination: Known as the “Acid-Base Balance Master,” this integrated sensor tracks both acidity and Oxidation-Reduction Potential. By maintaining an ORP range of 250-350mV, we ensure optimal conditions for nitrifying bacteria. This architectural oversight has reduced the need for external pH regulators by 30%.

- Nitrogen Cycle Trio (Ammonia, Nitrite, Nitrate): This module serves as a “Digital Twin” of the biological filter. Using a combination of UV absorption and ion-selective electrodes, it simultaneously tracks the three stages of nitrogen transformation, allowing us to visualize nitrification efficiency in real-time.

- Turbidity & Dissolved CO2: Critical for high-density vertical systems, Turbidity sensors monitor suspended solids to prevent gill irritation in fish, while CO2 sensors ensure that plant respiration does not acidify the water during dark cycles.

- Conductivity (EC) & Temperature: In a 9-meter vertical tower, temperature stratification can vary by up to 3°C between the base and the peak. Our sensors feature automatic temperature compensation to ensure EC readings (nutrient concentration) remain accurate regardless of thermal gradients, preventing uneven fertilization.

3. Hardware Solutions & Connectivity: LoRaWAN & Edge Computing

Our hardware deployment is designed for maximum interoperability and minimal maintenance in harsh, humid environments.

- Handheld Multi-Parameter Meters: Designed for mobile technicians to perform manual spot checks and verification of automated nodes.

- Floating Buoy Systems: Solar-powered autonomous stations for large-scale open water or large-pond monitoring, featuring multi-parameter integration.

- Self-Cleaning Industrial Probes: To combat bio-fouling—the primary cause of sensor drift—these units utilize hydrophobic nano-coatings and integrated ultrasonic cleaning brushes. These activate every 8 hours, extending the manual maintenance cycle from weekly to quarterly.

Connectivity & Architectural Intelligence

The backbone of the system is a LoRaWAN-enabled architecture. This protocol was selected specifically for its ability to penetrate high-density vertical metal racking, which typically causes significant signal attenuation for WIFI or GPRS signals.

|

Module Type

|

Primary Benefit

|

Best Application

|

Data Range/Power

|

|---|---|---|---|

|

LoRaWAN / LoRa

|

High penetration through metal; Long-range

|

Large-scale vertical farms/Commercial sites

|

Up to 15km; Ultra-low power

|

|

GPRS / 4G

|

Ubiquitous cellular access; High bandwidth

|

Remote urban facilities with existing cell

|

Global coverage; Moderate power

|

|

WIFI

|

High bandwidth; Low infrastructure cost

|

Small-scale indoor/R&D systems

|

Short range; High power

|

|

RS485

|

High-reliability wired connection

|

Industrial integrated rack-mount systems

|

Wired; Fixed power

|

The Edge Computing Advantage: By utilizing Edge Computing, sensor nodes process data locally. The system only uploads anomalies or filtered trend reports to the cloud, reducing data transmission volume by 90%. More importantly, edge logic allows for zero-latency local control, such as triggering emergency aeration even if the primary cloud connection is lost.

4. Data-Driven Results: Real-World Case Studies

- Preventative Ammonia Management At 3:00 AM, the system detected a non-linear ammonia spike. The Multi-parameter Correlation Algorithm identified that while DO and pH were dropping, EC remained stable—indicating a microbial community shift rather than simple hypoxia. Result: 6-hour pre-warning window provided, allowing for a 50% increase in aeration and backup filter activation before fish health was compromised.

- Precision Nutrient Optimization By correlating EC data with plant growth imagery, the system identified a specific potassium deficiency at the top of the 9-meter towers. Result: 22% yield increase and measurable improvements in Vitamin C content in lettuce harvests through targeted nutrient dosing.

- Energy OPEX Reduction Nocturnal data analysis revealed that fish oxygen consumption was 30% lower than daytime peaks. Result: 15,000 kWh/year electricity savings achieved by optimizing aeration intensity between 12:00 AM and 5:00 AM.

5. Economic Impact & ROI Analysis

Deploying a smart monitoring platform is a strategic investment in risk mitigation and resource efficiency.

Investment vs. Return

|

Metric

|

Impact Data

|

|---|---|

|

Initial Investment

|

$80,000 – $100,000

|

|

Fish Mortality Rate

|

Reduced from 5% to 0.8%

|

|

Feed Efficiency Ratio (FER)

|

Improved from 1.5 to 1.8

|

|

Vegetable Yield

|

35% Increase

|

|

Labor Costs

|

60% Reduction (Monitoring/Testing)

|

|

Payback Period

|

12 – 18 Months

|

6. Future Outlook: Standards and Traceability

The industry is moving toward a standardized, transparent future where data is the ultimate currency.

- Global Standardization: Agricultural departments are now setting benchmarks for sensor accuracy and sampling frequency to ensure food safety in recirculating systems.

- AI-Predictive Modeling: Future iterations will integrate market and weather data to predict water quality fluctuations and yield timing days in advance.

- Full-Chain Traceability: Consumers will soon scan a QR code on their produce to view a complete “growth environmental record,” proving the food was grown in optimal, safe conditions.

7. Frequently Asked Questions (FAQ)

1.Why is LoRaWAN preferred over WIFI for vertical aquaponics?

LoRaWAN excels in high-interference environments. Vertical farms are often filled with metal racks and water pipes that block WIFI signals. LoRaWAN’s sub-GHz frequency penetrates these obstacles effortlessly while providing long-range logging.

2.How do you handle sensor drift and bio-fouling?

We utilize sensors with hydrophobic nano-coatings and ultrasonic self-cleaning brushes. This technology reduces the maintenance requirement from once a week to once every three months, significantly lowering labor OPEX.

3.Is this system scalable for smaller operators?

Absolutely. The architecture is modular. Smaller farms can deploy a “Core Kit” (DO, pH, and Temperature) and add Nitrogen Cycle or CO2 modules as their budget and production capacity expand.

8. Call to Action

The future of agriculture is not just about growing; it is about listening to the data. Upgrade your water quality monitoring infrastructure today to transition from experience-based guesswork to architectural precision.

For more water quality monitoring information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-29-2026