Executive

A pH sensor that is kept alive in strong acid wastewater must be cleaned regularly, calibrated precisely at three points, and use high-impedance, integrated electrodes. Proper care guarantees that the sensor keeps up its 0.02 pH accuracy and 0.01 pH resolution even in rough 0 – 14 pH surroundings. Operators can prevent mineral scale buildup and use strong signal processing to keep the electrochemical potential from drifting, making sure that the chemical neutralization process will last for a long time.

Why Strong Acid Wastewater Challenges pH Sensors

1.Chemical Corrosion of Housing

2.Electrochemical Potential and Electrode Drift

Step-by-step maintenance protocol for acidic environment

The only way to have that level of precision for such an important piece of industrial monitoring equipment is to stick with a disciplined maintenance schedule.

- Cleaning and Scaling Removal: Periodically remove the sensor to inspect for mineral scaling or corrosive deposits. Because this sensor features standard G3/4 threads, it can be easily unscrewed from standard industrial pipe fittings for quick inspection. Use a soft cloth or a dilute cleaning solution that targets specific mineral build-up without abrading the glass membrane.

- Three-Point Calibration: Calibration must be performed using the three-point method to maintain linearity across the full spectrum. Use standard buffers at pH 4.0, pH 6.86, and pH 9.18. This ensures the sensor is accurate at the acidic, neutral, and slightly alkaline points often encountered during neutralization.

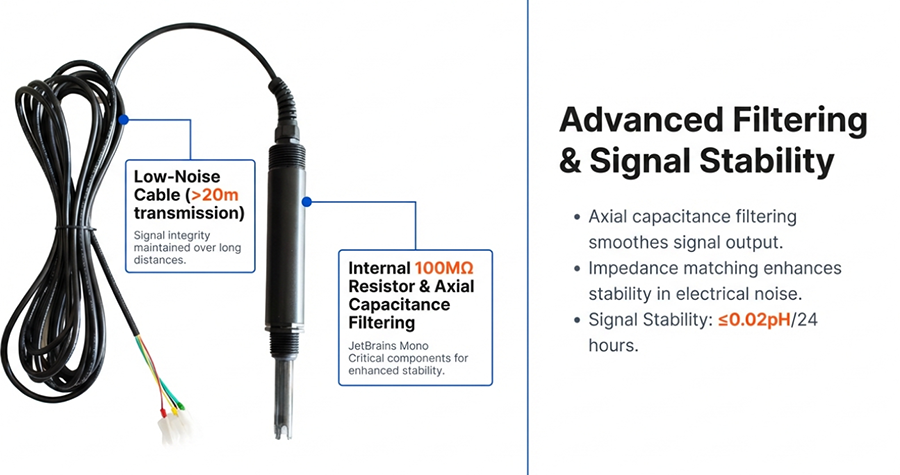

- Cable Integrity Inspection: Check the high-quality, low-noise cables for signs of acid damage or brittleness. While these cables are designed for signal integrity over runs exceeding 20 meters (and up to 1000m via RS485), physical breaches in the jacket can introduce electrical noise.

- Signal Stability Verification: Use your RS485 MODBUS or 4-20mA output to monitor stability. Under normal operating conditions, you should expect a stability of ≤0.02pH over a 24-hour period.

Technical Specifications for High-Acidity Monitoring

|

Parameter

|

Specification

|

Advantage for Acidic Waste

|

|---|---|---|

|

Measure Range

|

0 ~ 14 pH

|

Full spectrum coverage for extreme acidity.

|

|

Accuracy

|

±0.02 pH; ±1mV

|

High precision for strict chemical dosing.

|

|

Resolution

|

0.01 pH; 1mV

|

Captures minute fluctuations in neutralization.

|

|

Stability

|

≤0.02 pH / 24 hours

|

Minimizes the need for frequent recalibration.

|

|

Output Options

|

RS485; 4-20mA; Voltage (0-2V, 0-2.5V, 0-5V, 0-10V)

|

Versatile integration with PLC/SCADA.

|

|

Physical Size

|

205mm (L); 75mm (Electrode L)

|

Compact footprint for various mounting styles.

|

|

Installation Thread

|

G3/4

|

Standardized for easy removal and cleaning.

|

|

Internal Resistor

|

100M

|

High impedance to resist electrical noise.

|

|

Protection Level

|

IP68; 3000V Isolation

|

Protects against surges and liquid ingress.

|

Pro-Tips for Enhanced Stability: The Engineer’s Perspective

- Combating Electrical “Chatter”: We integrated axial capacitance filtering and a 100M internal resistor specifically to outperform standard electrodes in environments with high VFD (Variable Frequency Drive) noise. This significantly reduces data “chatter,” allowing you to identify when a sensor actually needs cleaning versus when it is simply experiencing electrical interference from nearby pumps.

- Design-Driven Longevity: Notice the “Before vs. After” design improvement in our latest generation. We have lengthened the signal processing section (total length 205mm). This modification allows the sensor to be installed in narrower ports while keeping the sensitive electronics and cable entry points further away from the hazardous acid splash zone. This effectively extends the Mean Time Between Failure (MTBF) by protecting the most vulnerable parts of the assembly from turbulent, high-acid flows.

- Surge Protection as Maintenance: Our sensor features up to four isolations with a 3000V protection grade. From a maintenance perspective, this is a lifesaver—it prevents the sensor from being “fried” by the massive electrical surges common in industrial pumping stations, reducing unscheduled replacements.

Implementation & System Integration

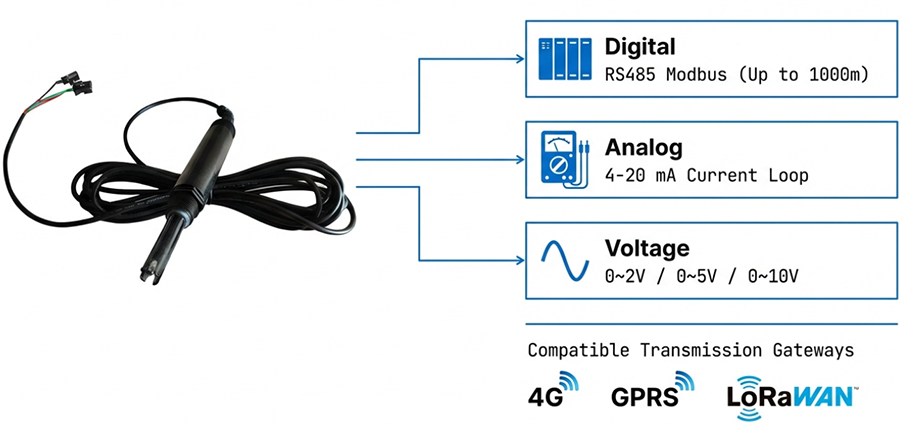

- Wired Reliability: RS485 (MODBUS protocol), can support up to 1000m of lead length, suitable for large scale treatment plant.

- Wireless Flexibility: 4G, GPRS and LoRaWAN fully compatible for real time maintenance alerts sent directly to a central cloud platform without any need for continuous manual on site inspection.

Conclusion

Don’t let the acid eat away at your information. Use sturdy stuff like ABS housing and high-impedance insides with active upkeep and a 3 point calender to make sure that your industrial wastewater is monitored properly, consistently, and without spending too much money.

For more water sensors information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-26-2026