With the rapid development of technologies such as the Internet of Things and artificial intelligence, gas sensors, an important sensing device known as the “electrical five senses”, are embracing unprecedented development opportunities. From the initial monitoring of industrial toxic and harmful gases to its wide application in medical diagnosis, smart home, environmental monitoring and other fields today, gas sensor technology is undergoing a profound transformation from a single function to intelligence, miniaturization and multi-dimensionality. This article will comprehensively analyze the technical characteristics, the latest research progress and the global application status of gas sensors, with particular attention to the development trends in the field of gas monitoring in countries such as China and the United States.

Technical characteristics and development trends of gas sensors

As a converter that converts the volume fraction of a specific gas into the corresponding electrical signal, the gas sensor has become an indispensable and important component in modern sensing technology. This type of equipment processes gas samples through detection heads, typically including steps such as filtering out impurities and interfering gases, drying or refrigeration treatment, and ultimately converting gas concentration information into measurable electrical signals. At present, there are various types of gas sensors on the market, including semiconductor type, electrochemical type, catalytic combustion type, infrared gas sensors and photoionization (PID) gas sensors, etc. Each of them has its own characteristics and is widely used in civil, industrial and environmental testing fields.

Stability and sensitivity are the two core indicators for evaluating the performance of gas sensors. Stability refers to the persistence of the basic response of a sensor throughout its entire working time, which depends on zero drift and interval drift. Ideally, for high-quality sensors under continuous working conditions, the annual zero drift should be less than 10%. Sensitivity refers to the ratio of the change in the sensor’s output to the change in the measured input. The sensitivity of different types of sensors varies significantly, mainly depending on the technical principles and material selection they adopt. In addition, selectivity (i.e., cross-sensitivity) and corrosion resistance are also important parameters for evaluating the performance of gas sensors. The former determines the sensor’s recognition ability in a mixed gas environment, while the latter is related to the sensor’s tolerance in high-concentration target gases.

The current development of gas sensor technology presents several obvious trends. First of all, the research and development of new materials and new processes has continued to deepen. Traditional metal oxide semiconductor materials such as ZnO, SiO₂, Fe₂O₃, etc. have become mature. Researchers are doping, modifying and surface-modifying existing gas-sensitive materials through chemical modification methods, and improving the film-forming process at the same time to enhance the stability and selectivity of sensors. Meanwhile, the development of new materials such as composite and hybrid semiconductor gas-sensitive materials and polymer gas-sensitive materials is also being actively advanced. These materials exhibit higher sensitivity, selectivity and stability to different gases.

The intelligence of sensors is another important development direction. With the successful application of new material technologies such as nanotechnology and thin-film technology, gas sensors are becoming more integrated and intelligent. By fully leveraging multi-disciplinary integrated technologies such as micro-mechanical and microelectronics technology, computer technology, signal processing technology, sensor technology, and fault diagnosis technology, researchers are developing fully automatic digital intelligent gas sensors capable of simultaneously monitoring multiple gases. A chemical resistance-potential type multivariable sensor recently developed by the research group of Associate Professor Yi Jianxin from the State Key Laboratory of Fire Science at the University of Science and Technology of China is a typical representative of this trend. This sensor realizes the three-dimensional detection and accurate identification of multiple gases and fire characteristics by a single device 59.

Arrayization and algorithm optimization are also receiving increasing attention. Due to the broad-spectrum response problem of a single gas sensor, it is prone to interference when multiple gases exist simultaneously. Using multiple gas sensors to form an array has become an effective solution to improve the recognition ability. By increasing the dimensions of the detected gas, the sensor array can obtain more signals, which is conducive to evaluating more parameters and improving the ability of judgment and recognition. However, as the number of sensors in the array increases, the complexity of data processing also rises. Therefore, the optimization of the sensor array is particularly important. In array optimization, methods such as correlation coefficient and cluster analysis are widely adopted, while gas recognition algorithms such as Principal Component Analysis (PCA) and artificial neural Network (ANN) have greatly enhanced the pattern recognition ability of sensors.

Table: Performance Comparison of Main Types of Gas Sensors

Sensor type, working principle, advantages and disadvantages, typical lifespan

Semiconductor-type gas adsorption has low cost in changing the resistance of semiconductors, fast response, poor selectivity, and is greatly affected by temperature and humidity for 2-3 years

Electrochemical gas undergoes REDOX reactions to generate current, which has good selectivity and high sensitivity. However, the electrolyte has limited wear and a lifespan of 1-2 years (for liquid electrolyte).

Catalytic combustion type combustible gas combustion causes temperature changes. It is specifically designed for combustible gas detection and is only applicable to combustible gas for approximately three years

Infrared gases have high accuracy in absorbing infrared light of specific wavelengths, do not cause poisoning, but have a high cost and a relatively large volume for 5 to 10 years

Photoionization (PID) ultraviolet photoionization for gas molecule detection of VOCs has high sensitivity and cannot distinguish the types of compounds for 3 to 5 years

It is worth noting that although gas sensor technology has made considerable progress, it still faces some common challenges. The lifespan of sensors restricts their application in certain fields. For instance, the lifespan of semiconductor sensors is approximately 2 to 3 years, that of electrochemical gas sensors is about 1 to 2 years due to electrolyte loss, while that of solid-state electrolyte electrochemical sensors can reach 5 years. In addition, drift issues (changes in sensor response over time) and consistency issues (performance differences among sensors in the same batch) are also important factors restricting the wide application of gas sensors. In response to these issues, researchers, on the one hand, are committed to improving gas-sensitive materials and manufacturing processes, and on the other hand, they are compensating for or suppressing the influence of sensor drift on measurement results by developing advanced data processing algorithms.

The diversified application scenarios of gas sensors

Gas sensor technology has permeated every aspect of social life. Its application scenarios have long transcended the traditional industrial safety monitoring scope and are rapidly expanding into multiple fields such as medical health, environmental monitoring, smart home, and food safety. This trend of diversified applications not only reflects the possibilities brought about by technological progress but also embodies the growing social demand for gas detection.

Industrial safety and hazardous gas monitoring

In the field of industrial safety, gas sensors play an irreplaceable role, especially in high-risk industries such as chemical engineering, petroleum, and mining. China’s “14th Five-Year Plan for the Safety Production of Hazardous Chemicals” clearly requires chemical industrial parks to establish a comprehensive monitoring and early warning system for toxic and harmful gases and promote the construction of intelligent risk control platforms. The “Industrial Internet Plus Work Safety Action Plan” also encourages parks to deploy Internet of Things sensors and AI analysis platforms to achieve real-time monitoring and coordinated response to risks such as gas leakage. These policy orientations have greatly promoted the application of gas sensors in the field of industrial safety.

Modern industrial gas monitoring systems have developed a variety of technical routes. Gas cloud imaging technology visualizes gas leakage by visually presenting gas masses as the changes in pixel gray levels in the image. Its detection capability is related to factors such as the concentration and volume of the leaked gas, background temperature difference, and monitoring distance. Fourier transform infrared spectroscopy technology can qualitatively and semi-quantitatively monitor over 500 types of gases including inorganic, organic, toxic and harmful ones, and can simultaneously scan 30 types of gases. It is suitable for the complex gas monitoring requirements in chemical industrial parks. These advanced technologies, when combined with traditional gas sensors, form a multi-level industrial gas safety monitoring network.

At the specific implementation level, industrial gas monitoring systems need to comply with a series of national and international standards. China’s “Design Standard for Detection and Alarm of Flammable and Toxic Gases in Petrochemical Industry” GB 50493-2019 and “General Technical Specification for Safety Monitoring of Major Hazard Sources of Hazardous Chemicals” AQ 3035-2010 provide technical specifications for industrial gas monitoring 26. Internationally, OSHA(Occupational Safety and Health Administration of the United States) has developed a series of gas detection standards, requiring gas detection before confined space operations and ensuring that the concentration of harmful gases in the air is below the safe level of 610. The standards of NFPA(National Fire Protection Association of the United States), such as NFPA 72 and NFPA 54, put forward specific requirements for the detection of flammable gases and toxic gases 610.

Medical health and disease diagnosis

The medical and health field is becoming one of the most promising application markets for gas sensors. The exhaled gas of the human body contains a large number of biomarkers related to health conditions. By detecting these biomarkers, early screening and continuous monitoring of diseases can be achieved. The handheld breathing acetone detection device developed by Dr. Wang Di’s team from Zhejiang Laboratory’s Super Perception Research Center is a typical representative of this application. This device utilizes a colorimetric technology route to measure the acetone content in human exhaled breath by detecting the color change of gas-sensitive materials, thereby achieving rapid and painless detection of type 1 diabetes.

When the insulin level in the human body is low, it is unable to convert glucose into energy and instead break down fat. As one of the by-products after fat breakdown, acetone is excreted from the body through respiration. Dr. Wang Di explained 1. Compared with traditional blood tests, this breath test method offers a better diagnostic and therapeutic experience. Moreover, the team is developing a “daily release” patch acetone sensor. This low-cost wearable device can automatically measure the acetone gas emitted from the skin around the clock. In the future, when combined with artificial intelligence technology, it can assist in the diagnosis, monitoring and medication guidance of diabetes.

Apart from diabetes, gas sensors also show great potential in the management of chronic diseases and the monitoring of respiratory diseases. The carbon dioxide concentration curve is an important basis for judging the pulmonary ventilation status of patients, while the concentration curves of certain gas markers reflect the development trend of chronic diseases. Traditionally, the interpretation of these data required the participation of medical staff. However, with the empowerment of artificial intelligence technology, intelligent gas sensors can not only detect gases and draw curves, but also determine the degree of disease development, greatly reducing the pressure on medical staff.

In the field of health wearable devices, the application of gas sensors is still in its early stage, but the prospects are broad. Researchers from Zhuhai Gree Electric Appliances pointed out that although household appliances are different from medical devices with disease diagnosis functions, in the field of daily home health monitoring, gas sensor arrays have advantages such as low cost, non-invasiveness and miniaturization, making them expected to increasingly appear in household appliances such as oral care appliances and smart toilets as auxiliary monitoring and real-time monitoring solutions. With the increasing demand for home health, monitoring human health status through household appliances will become an important direction for the development of smart homes.

Environmental monitoring and pollution prevention and control

Environmental monitoring is one of the fields where gas sensors are most widely applied. As the global emphasis on environmental protection continues to increase, the demand for monitoring various pollutants in the atmosphere is also growing day by day. Gas sensors can detect harmful gases such as carbon monoxide, sulfur dioxide and ozone, providing an effective tool for monitoring environmental air quality.

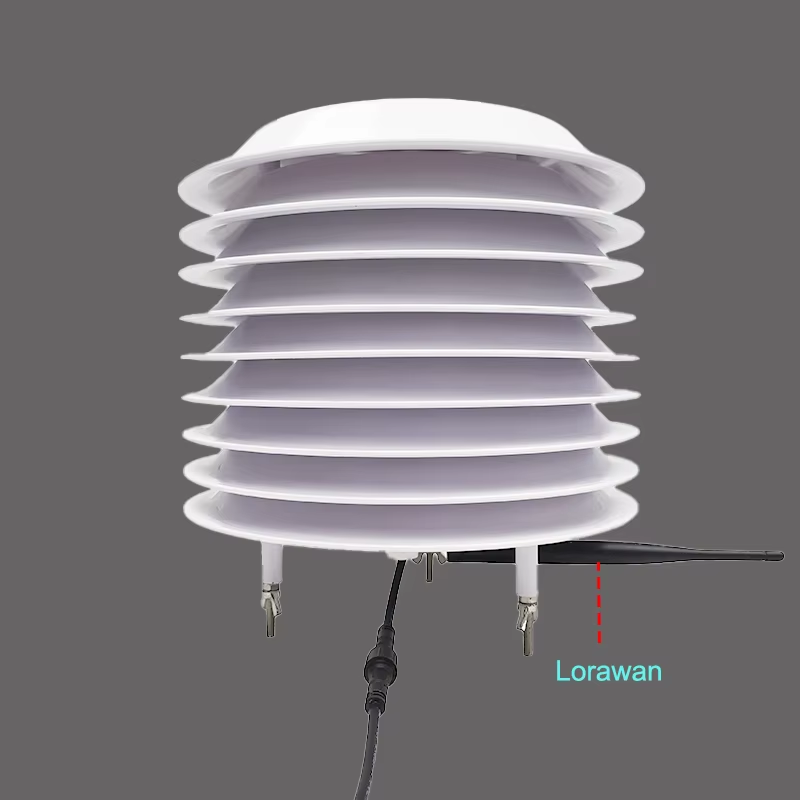

The UGT-E4 electrochemical gas sensor of the British Gas Shield Company is a representative product in the field of environmental monitoring. It can accurately measure the content of pollutants in the atmosphere and provide timely and accurate data support for environmental protection departments. This sensor, through integration with modern information technology, has achieved functions such as remote monitoring, data upload, and intelligent alarm, significantly enhancing the efficiency and convenience of gas detection. Users can keep track of the changes in gas concentration anytime and anywhere simply through their mobile phones or computers, providing a scientific basis for environmental management and policy-making.

In terms of indoor air quality monitoring, gas sensors also play an important role. The EN 45544 standard issued by the European Committee for Standardization (EN) is specifically for indoor air quality testing and covers the testing requirements for various harmful gases 610. Common carbon dioxide sensors, formaldehyde sensors, etc. in the market are widely used in civil residences, commercial buildings and public entertainment venues, helping people create a healthier and more comfortable indoor environment. Especially during the COVID-19 pandemic, indoor ventilation and air quality have received unprecedented attention, further promoting the development and application of related sensor technologies.

Carbon emission monitoring is an emerging application direction of gas sensors. Against the backdrop of global carbon neutrality, precise monitoring of greenhouse gases such as carbon dioxide has become particularly important. Infrared carbon dioxide sensors have unique advantages in this field due to their high precision, good selectivity and long service life. The “Guidelines for the Construction of Intelligent Safety Risk Control Platforms in Chemical Industrial Parks” in China has listed combustible/toxic gas monitoring and leakage source tracing analysis as mandatory construction contents, which reflects the policy level’s emphasis on the role of gas monitoring in the environmental protection field.

Smart Home and Food Safety

Smart home is the most promising consumer application market for gas sensors. At present, gas sensors are mainly applied in home appliances such as air purifiers and fresh air conditioners. However, with the introduction of sensor arrays and intelligent algorithms, their application potential in scenarios such as preservation, cooking, and health monitoring is gradually being tapped.

In terms of food preservation, gas sensors can monitor the unpleasant odors released by food during storage to determine the freshness of the food. Recent research results show that whether a single sensor is used to monitor the odor concentration or a gas sensor array combined with pattern recognition methods is adopted to determine the freshness of food, good effects have been achieved. However, due to the complexity of actual refrigerator usage scenarios (such as interference from users opening and closing doors, starting and stopping compressors, and internal air circulation, etc.), as well as the mutual influence of various volatile gases from food ingredients, there is still room for improvement in the accuracy of food freshness determination.

Cooking applications are another important scenario for gas sensors. There are hundreds of gaseous compounds produced during the cooking process, including particulate matter, alkanes, aromatic compounds, aldehydes, ketones, alcohols, alkenes and other volatile organic compounds. In such a complex environment, gas sensor arrays show more obvious advantages than single sensors. Studies show that gas sensor arrays can be used to determine the cooking status of food based on personal taste, or as an auxiliary dietary monitoring tool to regularly report cooking habits to users. However, cooking environment factors such as high temperature, cooking fumes and water vapor can easily cause the sensor to “poison”, which is a technical problem that needs to be solved.

In the field of food safety, the research of Wang Di’s team has demonstrated the potential application value of gas sensors. They aim at the goal of “identifying dozens of gases simultaneously with a small mobile phone plug-in”, and are committed to making food safety information readily available. This highly integrated array olfactory device can detect volatile components in food, determine the freshness and safety of food, and provide real-time references for consumers.

Table: Main Detection Objects and technical characteristics of gas sensors in various application fields

Application fields, main detection objects, commonly used sensor types, technical challenges, development trends

Industrial safety combustible gas, toxic gas catalytic combustion type, electrochemical type, harsh environment tolerance multi-gas synchronous monitoring, leakage source tracing

Medical and health acetone, CO₂, VOCs semiconductor type, colorimetric type selectivity and sensitivity, wearable and intelligent diagnosis

Long-term stability grid deployment and real-time data transmission for environmental monitoring of air pollutants and greenhouse gases in infrared and electrochemical forms

Smart home food volatile gas, cooking smoke semiconductor type, PID anti-interference capability

Please contact Honde Technology Co., LTD.

Email: info@hondetech.com

Company website: www.hondetechco.com

Tel: +86-15210548582

Post time: Jun-11-2025