Reliable industrial-grade soil NPK sensors for smart agriculture must prioritize hardware resilience and data interoperability. Procurement teams should mandate an IP68 waterproof rating and a standardized RS485 Modbus-RTU output to ensure long-term burial and seamless integration into automated fertigation systems. High-accuracy units, typically utilizing a three-needle probe electrode structure, provide data stabilization within one second of active monitoring. These sensors are engineered for 24/7 continuous operation, featuring internal circuitry protected by high-density epoxy resin to prevent corrosion in high-salinity or high-moisture environments.

Industrial Soil NPK Sensor Technical Parameters

Procurement teams must prioritize the following parameters to ensure system interoperability and performance in extreme field conditions:

| Parameter | Specification | Details |

| Measurement Range | 0 ~ 1999 mg/kg | Applicable to Nitrogen (N), Phosphorus (P), and Potassium (K) individually. |

| Measurement Accuracy | ±2% FS | High-precision monitoring for professional-grade soil nutrient analysis. |

| Resolution | 1 mg/Kg (mg/L) | Delivers granular data required for precise fertigation adjustments. |

| Working Temperature | -30°C ~ 70°C | Engineered for stability in both sub-zero and high-heat climates. |

| Output Signal | RS485 (Modbus-RTU) | Standard protocol; device default address is 01. |

| Supply Voltage | 12 ~ 24V DC | Standardized for industrial IoT power infrastructure. |

| Response Time | < 1 second | Real-time data refresh rate once the sensor is active. |

| Stabilization Time | 5 ~ 10 Minutes | Critical “warm-up” period after power-on for full system readiness. |

| Sealing Material | ABS Plastic / Epoxy Resin | High-density sealing to protect internal electronics from ingress. |

| Waterproof Grade | IP68 | Submersible design; supports permanent 24/7 soil burial. |

| Cable Specification | Standard 1 Meter | Customizable up to 1200 meters for large-scale farm layouts. |

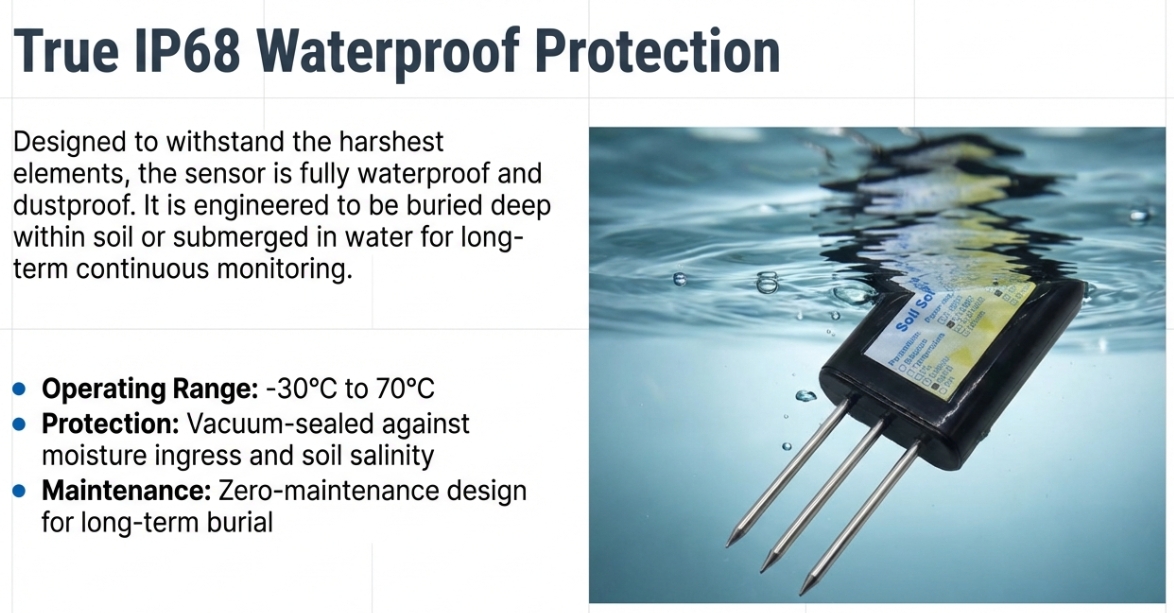

Why IP68 Sealing and Epoxy Resin Design are Critical for Soil IoT

In our manufacturing and field testing of soil IoT hardware, we have identified that environmental ingress—specifically moisture and soil salinity—is the primary driver of sensor drift and failure. To mitigate this, industrial NPK sensors utilize a high-density epoxy resin vacuum-sealing process combined with ABS engineering plastics. This is not merely for waterproofing; it is an engineering requirement to protect the internal circuitry from the corrosive effects of soil nutrients and electrolytes over a 3-year lifecycle.

The IP68 rating ensures the sensor can be totally buried for 24/7 continuous monitoring. This durability makes the sensor suitable for applications beyond agriculture, including oil/gas pipeline leakage monitoring and infrastructure anti-corrosion projects. Furthermore, these units are designed with integrated lightning protection and shielding against radio frequency electromagnetic radiation to maintain data integrity in industrial environments.

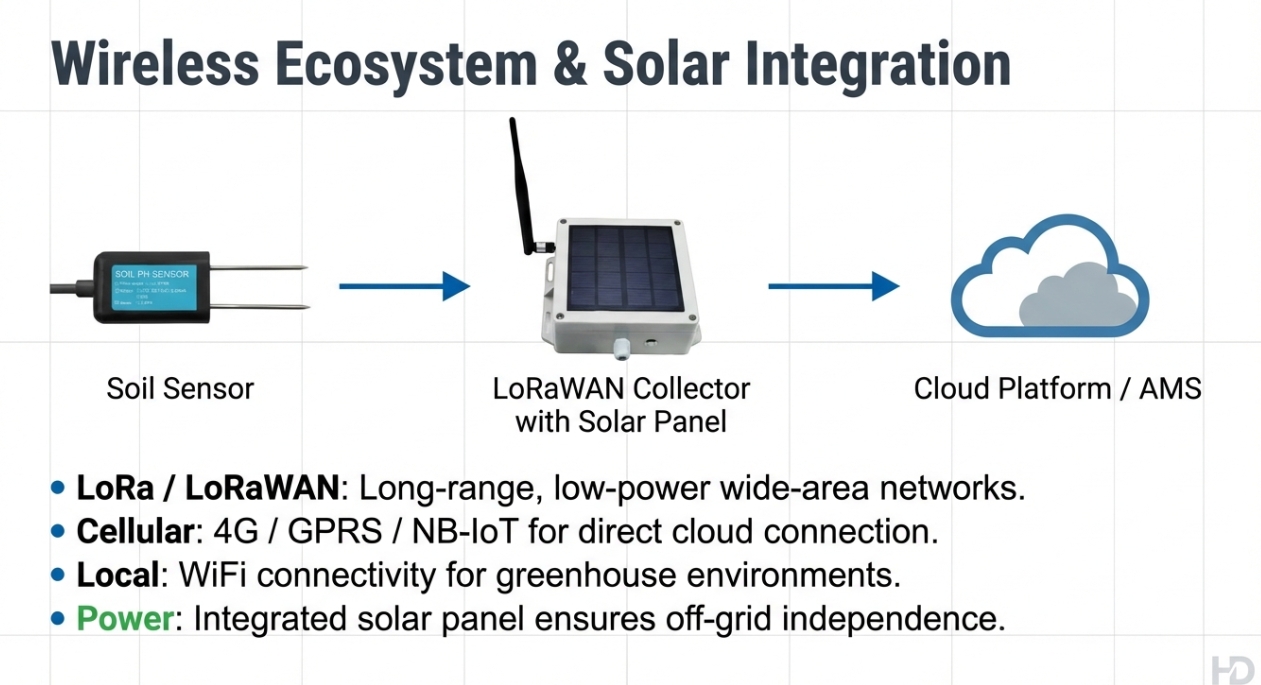

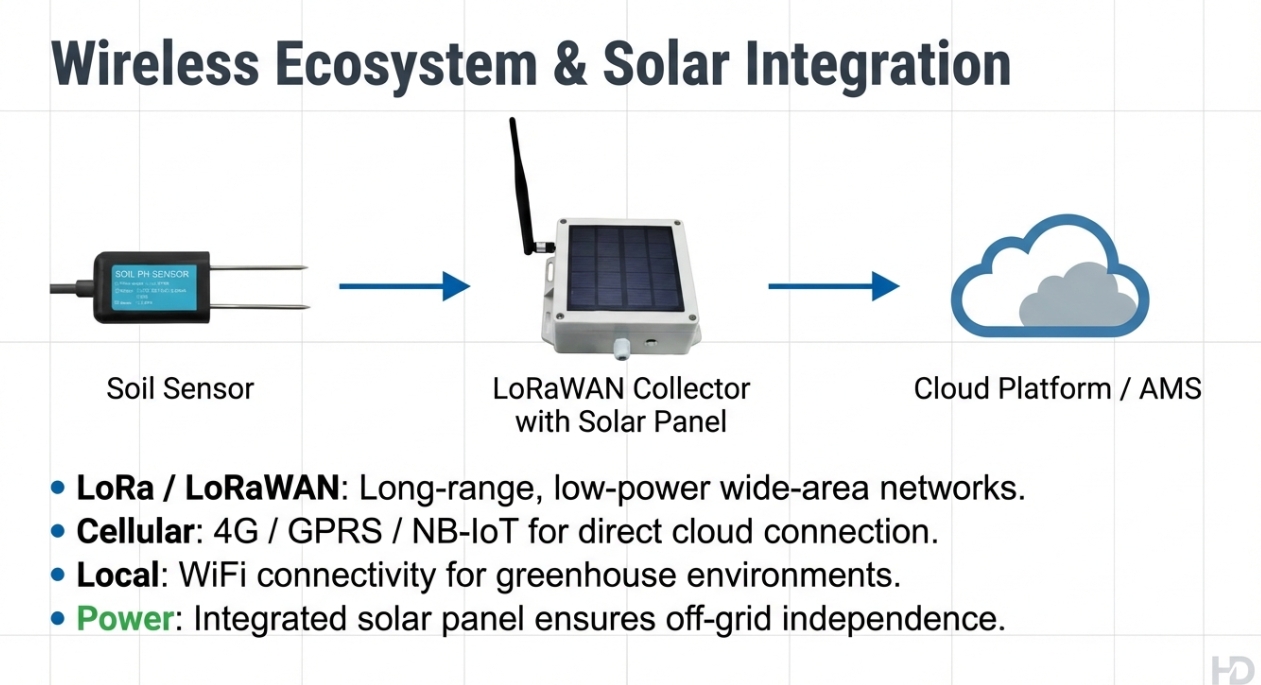

Streamlining Data Collection: LoRaWAN and Wireless Transmission Modules

Modern smart agriculture requires a “zero-infrastructure” approach to connectivity. Our sensor ecosystem supports a variety of wireless transmission modules to overcome the limitations of traditional wired layouts:

- Wireless Protocols: Full support for LoRaWAN, LORA, GPRS, 4G, WIFI, and NB-IoT.

- Solar-Powered LoRaWAN Collectors: Designed for remote acreage, these collectors utilize integrated solar panels to provide autonomous power for 24/7 data transmission.

- Data Logging & Local Visualization: Optional data loggers feature SD card storage and integrated screens for on-site troubleshooting.

- Expansive Cable Architecture: While the standard cable is 1m, the RS485 architecture allows for customization up to 1200 meters, enabling a centralized data hub for massive agricultural plots.

Real-World Performance: Analyzing Field Stability and Calibration Data

Field data from the 2025 India Soil Testing Report confirms the sensor’s ability to maintain high precision across diverse soil chemistries. During validation, the sensors demonstrated exceptional stability in both acidic (pH 4.00) and neutral-to-alkaline (pH 6.86–7.92) solutions.

Ground Truth Data Points:

- Nutrient Precision: Nitrogen values at 194 mg/kg, Phosphorus at 1000 mg/kg, and Potassium at 1546 mg/kg were recorded with high repeatability.

- Environmental Stability: The sensor maintained accurate EC (Conductivity) readings around 496–500 µs/cm and temperature stability between 15°C and 17°C during rigorous field cycles.

Understanding Stabilization vs. Response Time: Buyers should distinguish between the 5–10 minute stabilization time (the initial warm-up period required for the internal electronics to reach equilibrium after power-on) and the <1 second response time (the speed at which the sensor updates data once initialized). This rapid refresh rate is vital for real-time fertigation feedback loops.

Field Installation SOP: Ensuring ±2% FS Accuracy

Adherence to these Standard Operating Procedures (SOPs) is mandatory to ensure the data reflects true soil conditions.

Surface Measure Method

- Preparation: Select a representative site and remove all surface debris and vegetation.

- Insertion: Insert the sensor probes vertically and completely into the soil.

- Compression: Manually compress the soil around the probes to ensure full, gap-free contact.

- Verification: Take multiple measurements across a 1-meter radius and calculate the average.

Buried Measure Method

- Excavation: Create a vertical soil profile between 20cm and 50cm in diameter, slightly deeper than the target depth.

- Horizontal Insertion: Insert the sensor probes horizontally into the wall of the soil profile to minimize the “chimney effect” of water drainage.

- Pro-Tip (Moisture Retention): Place the excavated soil into numbered bags. Backfill the hole in the original layered order, compacting each layer to maintain the native soil density and moisture profile.

- Final Sealing: Ensure the lead wire is positioned to prevent water from tracking directly down to the sensor body.

Due to the presence of radio frequency electromagnetic radiation, sensors should not be energized in open air for extended periods. Only apply power once the probes are fully inserted into the soil or test medium to prevent potential sensor damage and ensure user safety.

Conclusion & B2B Call to Action

Industrial soil NPK sensors represent a high-ROI investment for 2026, offering a 3-year minimum lifetime and a standard 1-year warranty. With rapid delivery (1–3 working days), these units are the industry standard for precision agriculture and pipeline monitoring.

Ready to upgrade your environmental monitoring?

- Download the full technical NPK datasheet

- Soil Health Monitoring

- Request a custom quote for your smart agriculture project

Post time: Feb-09-2026