1. Multi-Platform Viral Headlines

- Unified Level and Quality Monitoring for Deep Wells

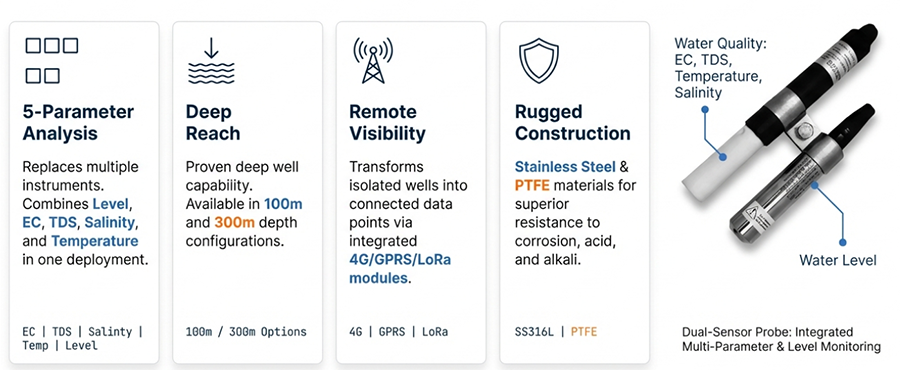

- Streamline your telemetry. 5 parameters, 1 sensor, 300-meter depth. The ultimate deep well solution is here.

- No more tangled cables. How to monitor a 300-meter well with just one integrated sensor.

- Reliable, corrosion-resistant monitoring for aquaculture and heavy industry. One unit handles level, EC, TDS, salinity, and temp.

- Integrated 5-in-1 Sensor for Deep Well Water Quality and Telemetry.

2. Introduction: Revolutionizing Deep Well Monitoring

3. Features

- Simultaneous Multi-Parameter Testing: Captures EC, Temperature, TDS, Salinity, and Liquid Level via one telemetry link.

- Built for extreme depth: optimized for deep water wells, configurations available for 100m and 300m.

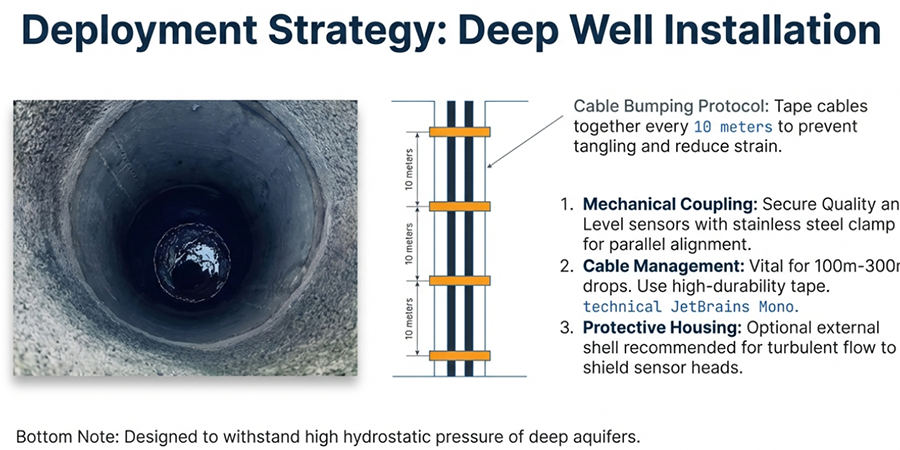

- Enhanced protection: An optional external protective shell for sensors at great depths and under high pressure.

- Physically Integrated & Replaceable: The sensors are physically attached using a special clamp and screw arrangement so that it is easy to maintain and replace components.

- Durable material science: Digital PTFE electrode on the water quality side and stainless steel compatible housing for the level sensor, resistant to corrosion, acid, and alkali.

- Industrial output versatility: RS485 (standard modbus-rtu, 9600 baud, 8-n-1) for full data sets, or analog options (4-20ma, 0-5v, 0-10v) for simplified salinity monitoring.

4. Technical Performance Visualization

|

Parameter

|

Measuring Range

|

Accuracy

|

Resolution

|

|---|---|---|---|

|

Liquid Level

|

0–10m (Up to 300m options)

|

0.2% FS

|

1mm

|

|

EC

|

0–2,000,000 μS/cm (20ms/cm)

|

±1% FS

|

10 μS/cm

|

|

TDS

|

0–100,000 ppm

|

±1% FS

|

10 ppm

|

|

Salinity

|

0–160 ppt

|

±1% FS

|

0.1 ppt

|

|

Temperature

|

0–60°C

|

±0.5°C

|

0.1°C

|

5. Smart wireless connectivity and cloud integration

The architecture is built for remote telemetry using a flexible 4G wireless module which supports multiple protocols such as GPRS, 4G, WIFI and LORA/LORAWAN.

- IP-Rated Deployment: Wireless Module is housed inside a professional Rainfall case that is made for direct outdoor mounting in harsh environment.

- Plug-and-Play Telemetry: Module has got two waterproof connectors for easy sensor connection.

- SIM management: A “yellow button” ejection mechanism for the SIM card slot provides high-speed 4G access.

- Architect-level precision: RS485 uses the standard Modbus-RTU protocol (Baud rate 9600, 8-N-1) to integrate with existing PLC/SCADA systems.

- Power Rail Compatibility:

8~24V DC: RS485, 0-2V/0-2.5V.

12~24V DC: For 0-5V, 0-10V, and 4-20mA signals.

6. Various application scenarios

Deep Well Monitoring: Precision Tap Water, Chemical Industry Well Management.

Environmental protection: real time online monitoring of sewage treatment and conservation.

Aquaculture & Food processing: Salinity and temperature controls for big time.

Thermal Power & Metallurgy: Industrial cooling and process water at high temp, high conductivity.

Hydrogeology&Industry:Specializedmonitoringforfermentation, electroplating,papermaking.

7. FAQ

Inquire Now for Technical Specifications and Customized Pricing

For more Water quality sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-28-2026