Introduction: The Critical Role of Accurate Rainfall Data

Precise precipitation data is the bedrock of modern environmental management and public safety. This information is foundational for a wide range of critical applications, from issuing timely flood disaster warnings and scheduling agricultural irrigation to planning and operating urban drainage systems. Among the tools used to gather this data, the Tipping Bucket Rain Gauge (TBRG) stands out as one of the most widely used instruments in global hydrometeorological monitoring networks.

Its popularity stems from a straightforward operating principle, the ease of generating a digital output, and its stable performance, particularly during high-intensity rain events. However, traditional designs have inherent accuracy challenges that can compromise data quality. This article explores the science of a modern TBRG that overcomes these challenges, leveraging advanced algorithms and practical design features to deliver a new level of precision grounded in verifiable industry standards.

1. Understanding the Tipping Bucket: A Classic Mechanism

The fundamental operating principle of a Tipping Bucket Rain Gauge is an elegant example of converting a continuous physical process into discrete, countable events. The process unfolds in a clear sequence:

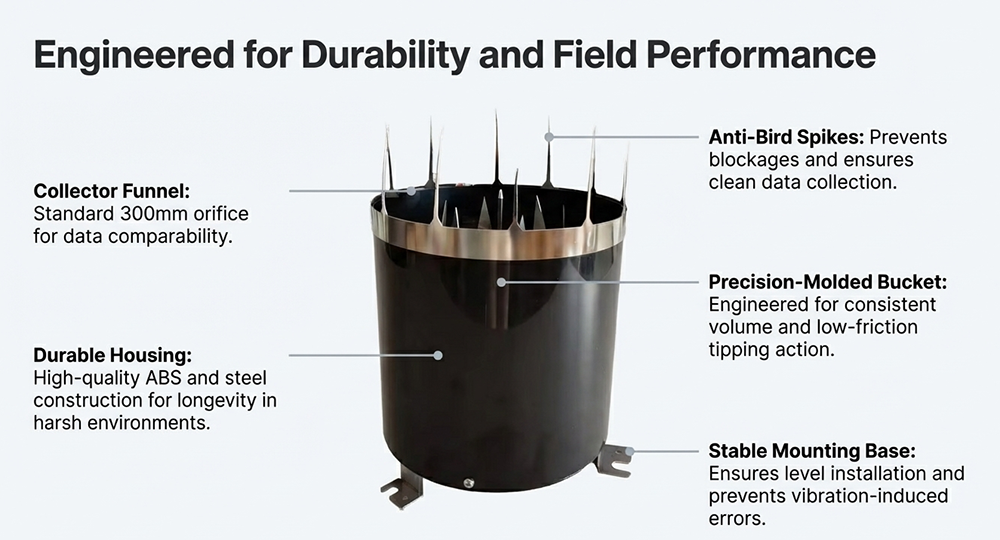

1. Collection: Rainwater is captured by a standard catch opening, a critical dimension whose diameter is often standardized at 300mm to ensure data comparability. The water is then directed through a filter screen, which removes leaves and debris, and into a funnel.

2. Measurement: From the funnel, the water flows into one of two balanced, symmetrical bucket chambers. This core component is a “mechanical bistable” structure, designed to pivot on a low-friction axis.

3. The “Tip”: When a predefined volume of water accumulates in the chamber—a volume that, per common industry standards, corresponds to a rainfall depth of 0.1mm—the resulting gravitational torque causes the entire bucket mechanism to lose balance and tip over.

4. Signal Generation: As the bucket tips, a small magnet sweeps past a reed switch, causing its internal contacts to close and generate a single electrical pulse. This action empties the full chamber while simultaneously positioning the empty chamber under the funnel to begin the next collection cycle. In advanced designs, the magnet is separated from the bucket onto a dedicated “counting swing mechanism,” a clever feature that prevents magnetic forces from interfering with the bucket’s tipping torque.

In a traditional system, each electrical pulse represents a fixed amount of rainfall. The total precipitation is therefore calculated by simply counting the number of pulses over a given period.

2. The Accuracy Challenge: Unmasking Inherent Errors

While the principle is simple, several physical factors introduce measurement errors under real-world conditions, preventing traditional gauges from achieving the high precision required for modern applications.

The Problem of ‘Dynamic Loss’

The primary cause of measurement error, especially during high-intensity rainfall, is a phenomenon known as “dynamic loss.” This refers to the rainwater that is lost during the brief moment—typically a fraction of a second—the bucket mechanism is in motion, tipping from one side to the other. During this transition, inflowing water from the funnel is not captured by either chamber and is lost from the measurement. This loss is directly proportional to the rainfall intensity; the heavier the rain, the faster the bucket tips, and the more water is lost between tips. This effect can lead to measurements that are 5% to 10% lower than the actual rainfall during a significant storm.

Other Key Error Sources

Beyond dynamic loss, several other factors contribute to measurement uncertainty:

• Adhesion and Evaporation: During light rain or at the start of an event, water adheres to the surfaces of the funnel and buckets. In dry or hot conditions, this moisture can evaporate before being measured, leading to underreporting of trace precipitation amounts.

• Splashing Error: High-velocity raindrops can strike the rim of the collector and splash out, while others can hit the inside of the funnel and splash back into a different bucket, causing both negative and positive errors.

• Mechanical Balance and Signal Debouncing: If the instrument is not perfectly level, the tipping torque for each bucket will be unequal, introducing a systematic error. Furthermore, the mechanical contact of the reed switch can “bounce,” creating multiple false signals from a single tip. Ineffective electronic debouncing logic can either miss legitimate tips during intense rain or count single tips multiple times.

Defining Precision: Industry Benchmarks

To be considered a reliable instrument, a rain gauge must meet stringent performance criteria. Industry standards, such as HJ/T 175—2005 in China, provide a quantitative framework for “high precision.” The 5% to 10% error from dynamic loss is a significant deviation when these standards require far greater accuracy. Key benchmarks include:

|

Parameter

|

Technical Requirement

|

|

Starting Monitoring Rainfall

|

≤ 0.5 mm

|

|

Measurement Error (for total rainfall ≤ 10 mm)

|

± 0.4 mm

|

|

Measurement Error (for total rainfall > 10 mm)

|

± 4%

|

|

Minimum Resolution

|

0.1 mm

|

Meeting these standards, especially the ±4% tolerance during heavy rain, is impossible for a traditional TBRG without an intelligent correction mechanism.

3. The Smart Solution: Achieving Precision with Advanced Algorithms

The modern solution to the accuracy problem is found not in a complex mechanical overhaul, but in intelligent software that works with the existing robust design. This approach corrects for inherent errors by adding a layer of digital intelligence to the proven mechanical system.

From ‘Count’ to ‘Characterization’: The Power of Bucket Duration

The core innovation lies in how the instrument processes each tip. Instead of simply counting pulses, the system’s internal high-frequency clock precisely measures the time interval between each consecutive tip. This interval is referred to as “bucket duration” .

This measurement provides a powerful new variable. There is an inverse relationship between bucket duration and rain intensity: a shorter duration signifies heavier rainfall, while a longer duration indicates lighter rain. The onboard microprocessor uses this bucket duration as a key input into a non-linear dynamic compensation model, which defines the relationship between the true rainfall amount per tip and the tip duration . This relationship, represented by a correction function

J = 0, allows the device to dynamically calculate the precise amount of rainfall for each individual tip. For tips with short durations (high intensity), the algorithm calculates a slightly larger rainfall value, effectively adding back the water that would have been lost due to the dynamic loss effect.This software-based approach embodies the principle of “cyclic correction, gradually approaching the ideal state.” It allows the instrument’s calibration to be fine-tuned and updated in the field by adjusting software parameters rather than making tedious mechanical adjustments to weights or screws. This is a major efficiency gain, drastically simplifying long-term maintenance and ensuring sustained accuracy.

4. Engineered for the Field: Practical Features and Applications

Beyond the internal technology, a modern rain gauge is engineered with practical features to ensure reliability and usability in demanding field conditions.

Ensuring Long-Term Reliability: The Anti-Nesting Advantage

Figure 1: The rain collector funnel equipped with anti-nesting spikes, a crucial feature for preventing blockages and ensuring long-term data integrity in the field.

A prominent feature of the collector is the array of sharp spikes arranged around its rim. This is a simple and highly effective deterrent that prevents birds from landing and building nests inside the gauge’s funnel. A bird’s nest is a primary cause of field failures, as it can completely block the funnel and lead to total data loss. This anti-nesting feature prevents such blockages, directly improving data availability, ensuring data integrity, and reducing costly site visits for maintenance.

Where Precision Matters: Key Application Scenarios

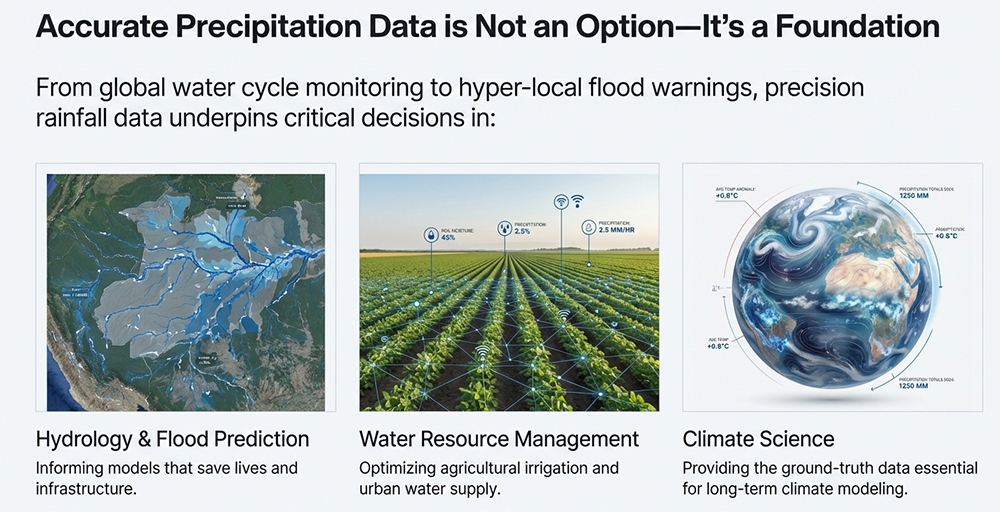

The high-accuracy data delivered by these advanced gauges is critical in numerous fields:

• Meteorology and Hydrology: Provides accurate data for water cycle monitoring, weather forecasting, and scientific research into climate patterns.

• Flood Warning and Prevention: Delivers reliable, real-time rainfall intensity data essential for early warning systems, helping to protect lives and property.

• Agricultural Management: Enables precision irrigation scheduling based on actual rainfall received, which helps conserve water resources and maximize crop yields.

• Urban Water Management: Supports the effective design and real-time operational control of city drainage networks and stormwater management systems to prevent urban flooding.

Comparative Context: A Balanced Solution

The modern, algorithm-corrected TBRG occupies a unique and valuable position among precipitation measurement technologies. While other instruments exist, they each come with significant trade-offs:

• Weighing Gauges: Offer the highest raw accuracy and can measure solid precipitation like snow. However, they are mechanically complex, extremely sensitive to wind-induced vibrations, and have a very high cost, making them impractical for wide-scale network deployment.

• Siphon Gauges: Provide a continuous record of rainfall but are prone to mechanical failures, require frequent maintenance, and have a “blind spot” during the rapid siphoning process.

• Optical Gauges: Have no moving parts and offer fast response times, but their accuracy depends on statistical models to convert light scatter into rainfall rates and can be compromised by fog or lens contamination.

The intelligent TBRG effectively closes the accuracy gap with expensive weighing gauges, particularly for liquid precipitation, while retaining the inherent robustness, low power consumption, and cost-effectiveness that made the original design so ubiquitous.

5. Conclusion: The Best of Both Worlds

The modern high-precision tipping bucket rain gauge successfully marries the proven durability and simplicity of a traditional mechanical design with the superior accuracy of an intelligent, software-driven correction system. By characterizing each tip based on its duration rather than just counting them, it overcomes the inherent dynamic loss that affects older models, allowing it to meet stringent industry accuracy standards across the full spectrum of rainfall intensities.

It strikes an optimal balance between precision and practicality. While weighing gauges may offer higher accuracy in a controlled environment, the algorithm-corrected TBRG delivers near-comparable performance with far greater resilience and cost-efficiency for large-scale networks. Combined with practical features engineered for long-term field deployment, it stands as a robust, precise, and low-maintenance solution for any professional requiring dependable, high-quality rainfall data.

Complete set of servers and software wireless module, supports RS485 GPRS /4g/WIFI/LORA/LORAWAN

For more rain gauge information,

please contact Honde Technology Co., LTD.

Email: info@hondetech.com

Company website: www.hondetechco.com

Tel: +86-15210548582

Post time: Dec-31-2025