1. The Hook: The Invisible Data Stream

For decades, professional-grade meteorological monitoring was a bulky and expensive endeavor that relied on “best guess” local readings or massive, mechanical arrays. These traditional setups required a sprawling collection of spinning anemometers and tipping buckets, all of which were prone to failure in the field. We are now witnessing a quiet revolution in the form of “micro-meteorological instruments,” compact devices that transform weather from a vague forecast into a high-resolution, invisible data stream. From solar farms to urban smart streets, this shift toward integrated sensing is redefining how we monitor our environment in real-time.

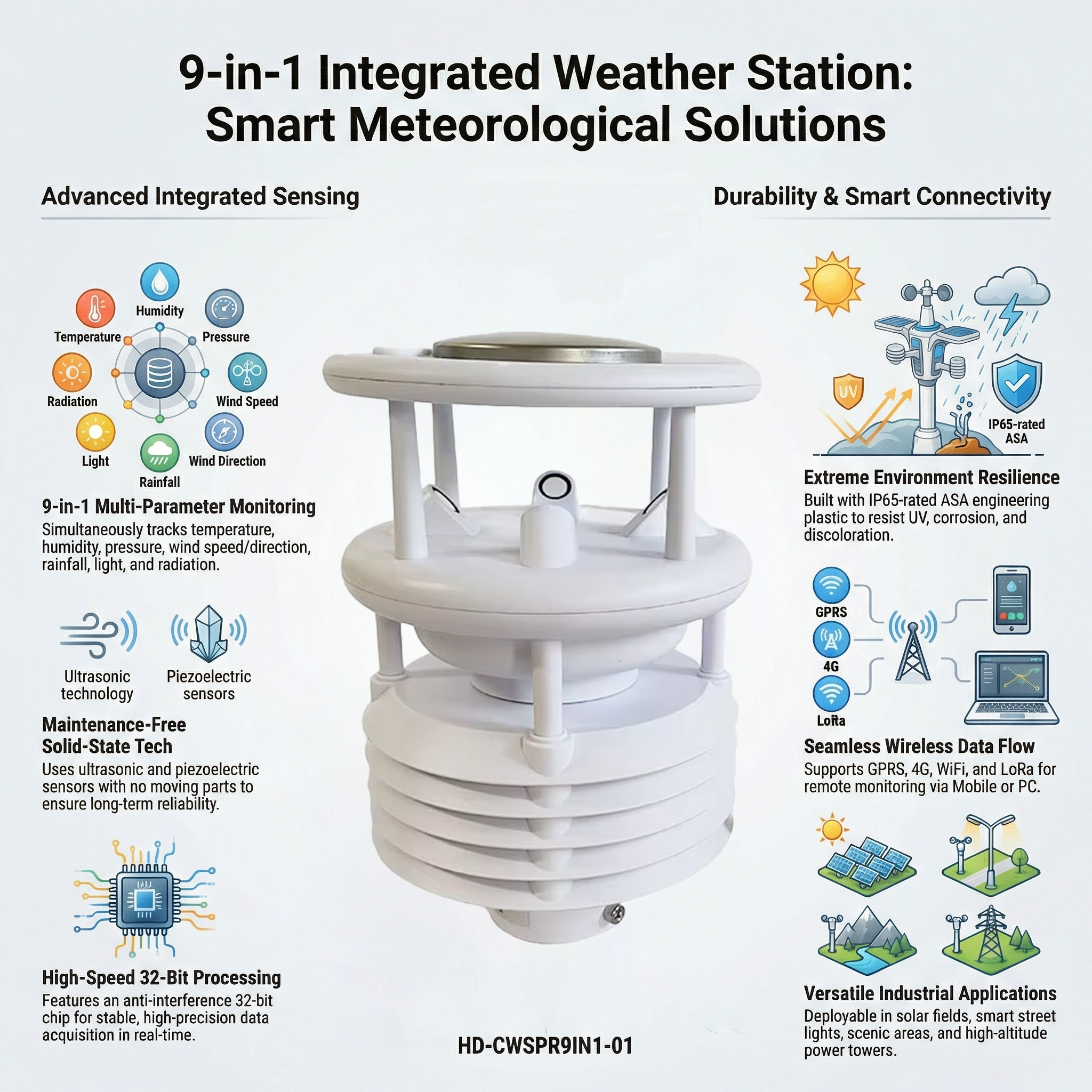

2. Moving Parts are a Thing of the Past

The HD-CWSPR9IN1-01 represents a strategic leap forward by moving into the realm of “Solid-State” technology, effectively eliminating the mechanical fatigue associated with traditional sensors. By utilizing an ultrasonic wind sensor to measure speeds up to 60m/s and a piezoelectric rainfall sensor, this device removes the vulnerabilities of spinning cups or freezing buckets. This transition to electronic sensing ensures the system remains maintenance-free, even when deployed in the most unforgiving industrial climates.

“The piezoelectric rainfall sensor is built for heavy dust and sand… it is free maintenance and different from the traditional tipping bucket.”

A Senior Strategist recognizes that the “9-in-1″ designation is about more than just data volume; it is about data integrity. To achieve this, the device integrates a specialized Rain and Snow Sensor that serves as a verification layer to cross-reference piezoelectric readings. This dual-sensor logic allows the system to determine if precipitation is actually occurring, drastically reducing the error rates often found in standalone sensors.

3. Eight Sensors, One Footprint: The Power of Integration

True operational efficiency is achieved through the device’s high level of technical integration, housing eight primary meteorological elements plus the verification sensor in a single unit. This modular design significantly reduces the Total Cost of Ownership (TCO) by simplifying installation and eliminating the need to mount and wire eight separate instruments. By consolidating these sensors, organizations can achieve a “grid deployment” that captures hyper-local data variations across a wide geographic area.

The system monitors a comprehensive environmental profile with high precision:

- Ambient Temperature: -40 to 85℃ (±0.3℃ accuracy)

- Relative Humidity: 0-100%RH (±3%RH accuracy)

- Atmospheric Pressure: 300-1100hPa (±0.3hPa accuracy)

- Wind Speed: 0-60m/s (Ultrasonic principle)

- Wind Direction: 0-360° (0.1° resolution)

- Rainfall: 0-200mm/h (Piezoelectric principle)

- Illuminance: 0-200KLUX (10LUX resolution)

- Radiation: 0-2000 W/m² (Distinct from light intensity)

With a remarkably low power consumption of <1W@12V, this unit is a primary enabler for solar-powered remote stations. The ability to distinguish between Illuminance (light intensity) and Radiation (solar energy) is particularly critical for industrial energy managers who require specific metrics to calculate solar plant performance.

4. Built for the Extremes (ASA Engineering Plastic)

When hardware is deployed on high-altitude towers or in sun-scorched deserts, material science becomes the ultimate guarantor of uptime. The HD-CWSPR9IN1-01 is encased in ASA engineering plastic, a high-grade material chosen specifically for its resistance to UV exposure, weathering, and corrosion. This IP65-rated housing ensures the internal 32-bit high-speed processing chip—the brain of the system—remains stable and shielded from electromagnetic interference.

Authoritative reliability is backed by more than just a datasheet; these units are subjected to rigorous wind tunnel testing to verify aerodynamic precision and refrigeration testing to ensure stability at temperature extremes. Whether operating at -40℃ or 85℃, the device maintains its calibration and structural integrity. This level of physical resilience is essential for maintaining data continuity in mission-critical industrial applications.

5. From the Field to the Cloud: Ubiquitous Connectivity

The true value of environmental intelligence lies in its accessibility, transforming raw measurements into actionable digital assets. The system supports RS485/Modbus RTU for seamless integration into existing industrial PLC networks, but its true flexibility shines in the wireless arena. By supporting modules such as GPRS, 4G, WiFi, and LoRaWAN, the device ensures that real-time visibility is never more than a click away.

This ubiquitous connectivity allows for “Real-time” monitoring via mobile clients, tablets, or web-based dashboards. Managers can now move past static, historical records and instead leverage a live environmental feed to make informed operational decisions. Whether monitoring a single site or a global fleet of assets, the digital pipeline remains robust and scalable.

6. Versatility in the Wild

The device’s adaptive “flexible layout” refers to its compact form factor and sleeve fixing mechanism, which allows for rapid integration into existing infrastructure. This design allows the sensor to be deployed on high-altitude iron towers or smart street lights without the need for expensive, custom retrofitting. Its small footprint and modular nature make it the ideal candidate for a wide range of Intelligent applications.

In solar power plants, the device provides the ground truth for radiation and temperature needed to calculate energy efficiency. Meanwhile, in scenic areas and agricultural zones, its low-maintenance design ensures that localized weather data is available without the burden of constant manual calibration. This versatility proves that the HD-CWSPR9IN1-01 is built to thrive wherever environmental data is needed most.

7. The Future of Environmental Intelligence

As we enter the Smart era, highly integrated, low-maintenance sensors are becoming the essential backbone of our digital infrastructure. They provide the high-fidelity data necessary to power AI-driven energy grids and autonomous urban ecosystems.

As these solid-state sensors become ubiquitous, we must consider the broader strategic implications. How will the availability of hyper-local, second-by-second weather data change the way we manage global food supplies and renewable energy distribution over the next decade?

Click to view HD-CWSPR9IN1-01 weather station technical parameters

For more weather station information, please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Feb-06-2026