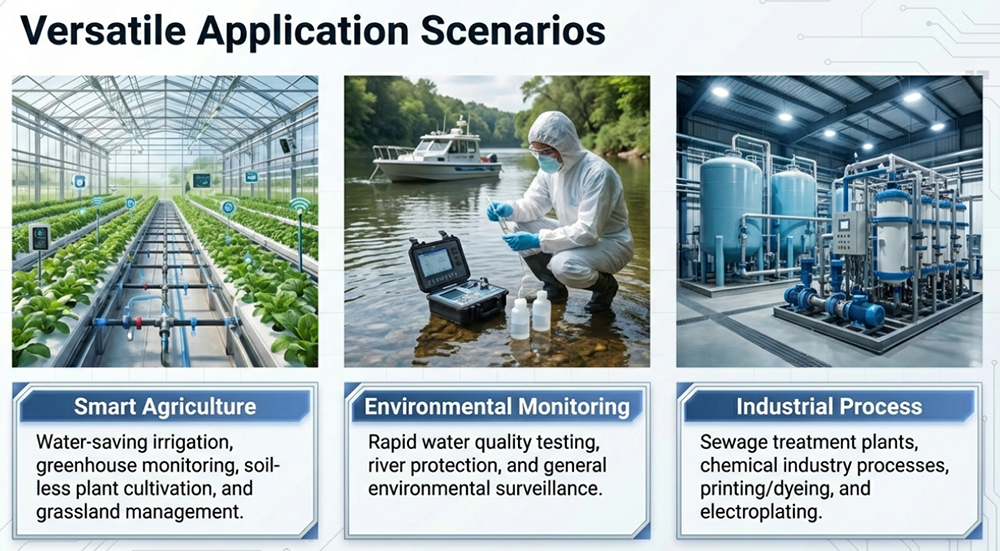

Introduction: The Complexity of Liquid Intelligence

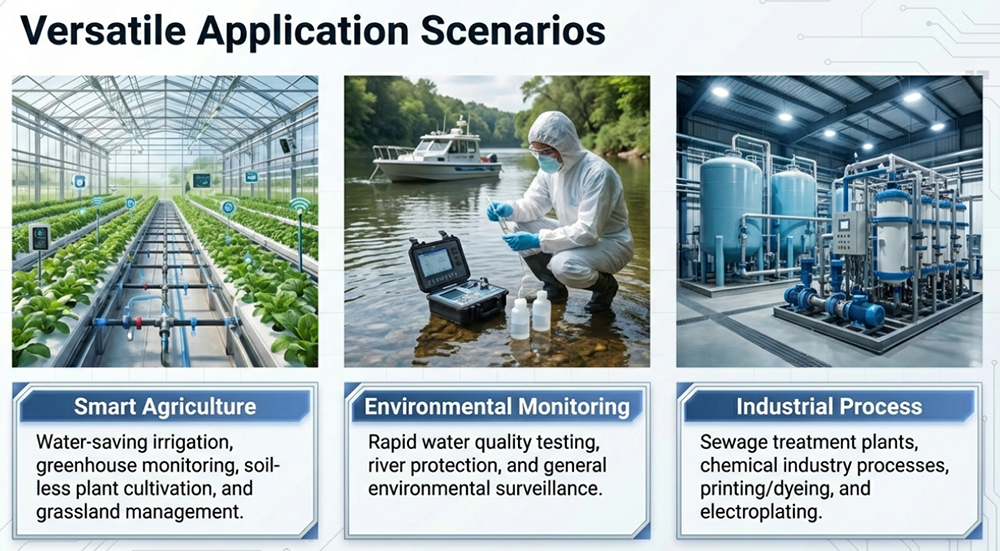

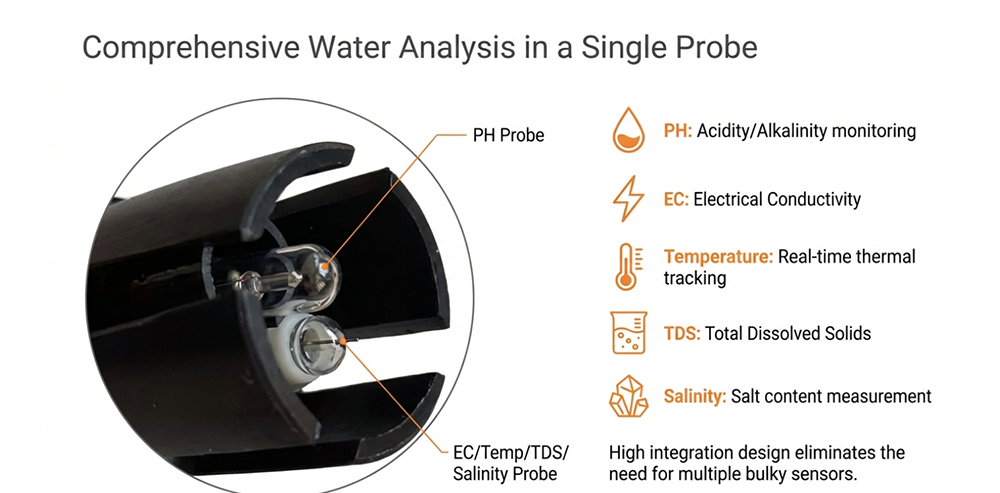

In modern industrial infrastructure, managing water quality has historically been a fragmented exercise in technical debt. Professionals in sectors ranging from precision agriculture to chemical processing have long struggled with the logistical burden of deploying multiple, bulky sensors to capture a single sample’s profile. Relying on separate probes for pH, conductivity, and salinity doesn’t just increase the physical footprint; it multiplies the points of failure and complicates data synchronization. As we move toward a future defined by real-time “liquid intelligence,” the industry requires a streamlined approach to signal acquisition. The RD-PETSTS-01 eliminates this frustration, replacing a tangle of cables with a single, high-performance integrated solution designed for the rigors of smart industry.

The Power of Five: Radical Integration in a Single Probe

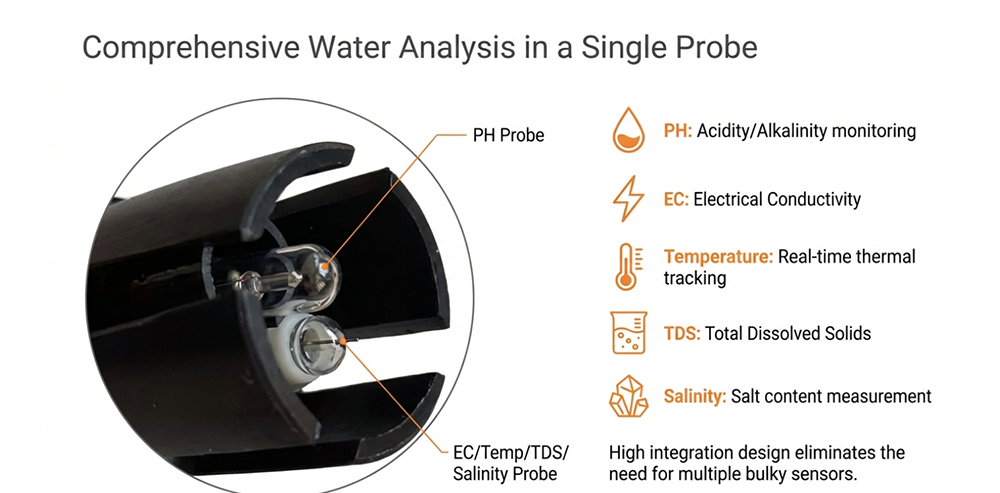

The RD-PETSTS-01 consolidates five critical telemetry parameters—pH, Electrical Conductivity (EC), Total Dissolved Solids (TDS), Salinity, and Temperature—into a single immersion-ready device. This integration ensures that all data points are captured from the exact same water volume simultaneously, providing a more accurate snapshot of solution dynamics than staggered individual probes. The sensor offers a robust operating envelope: pH from 0–14, EC up to 10,000us/cm, TDS up to 5,000ppm, Salinity at 8ppt, and a temperature range of 0–60℃. By reducing the hardware overhead and simplifying the wiring to a single four-wire connection, operators can:

“Truly achieve low cost, low price and high performance.”

Engineering for “Complex Interference”

Industrial environments like electroplating facilities and sewage treatment plants are notorious for electrical noise that can degrade low-voltage signals. To ensure data stability, the RD-PETSTS-01 utilizes internal axial capacitor filtering and a 100M resistor to significantly increase input impedance. This is a vital engineering choice for maintaining signal integrity and preventing attenuation over the long industrial cable runs typical of large-scale infrastructure. With “four isolations” and an IP68 waterproof rating, the sensor is purpose-built to withstand site interference while delivering precise RS485 differential inputs to your data acquisition system.

Size Matters: The 42mm Advantage

Physical constraints are often the primary barrier to high-fidelity monitoring in existing infrastructure. The RD-PETSTS-01 addresses this with a compact 202mm length and a 42mm body diameter that tapers to a 34mm tip. This tapered profile is specifically designed for deployment in “small pipes” and restricted apertures where standard industrial sensors cannot fit. Being “small in size, highly integrated, [and] easy to carry,” it serves dual roles: a permanent fixture in tight plumbing and a portable tool for rapid field testing in agricultural greenhouses or urban drainage systems.

Seamless Connectivity from Field to Cloud

Connectivity is what transforms a hardware tool into a true IoT node. Operating on a 12~24V DC power supply, the sensor communicates via the industry-standard RS485 interface using the Modbus-RTU protocol (9600 baud rate). For technicians in the field, the device supports a 0XFE broadcast address, a critical fail-safe for querying the original address if it has been forgotten or misconfigured. Integration is seamless; the sensor can be configured via a USB-to-RS485 connector for PC-level setup and paired with wireless collectors supporting WIFI, GPRS, 4G, LoRa, or LoRaWAN. This enables a complete “Data Acquisition System” that streams real-time telemetry to matched cloud server software for remote monitoring.

Precision Through Multi-Point Calibration

Maintaining industrial-grade accuracy—±0.1PH for acidity and ±1% FS for salinity—requires a robust calibration protocol. The RD-PETSTS-01 supports user-driven secondary calibration, allowing for fine-tuning via Modbus registers. Operators can perform three-point pH calibration using standard solutions (4.01, 6.86, and 9.18) and adjust the EC slope using the industry-standard 1413us/cm solution. This level of granular control is essential for maintaining the sensor’s ±0.5℃ temperature precision and overall measurement stability across its lifecycle, ensuring it meets the strict tolerances of the pharmaceutical and environmental protection sectors.

Conclusion: Toward a Smarter, Simpler Water Future

The RD-PETSTS-01 represents a shift away from “sensor sprawl” toward highly integrated, resilient infrastructure. By lowering the physical and financial barriers to multi-parameter water monitoring, this 5-in-1 probe allows industries to transition from reactive sampling to proactive, data-driven management. As you evaluate your current monitoring stack, consider the logistical and analytical overhead of your existing probes. How much hidden efficiency could you unlock by upgrading to a more streamlined, “liquid intelligence” architecture?

Tags: water ec sensor | water PH sensor |Water turbidity sensor|Water dissolved oxygen sensor|Water ammonium ion sensor|Water nitrate ion sensor

For more Water quality sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time:

Jan-15-2026