1. Introduction: The Evolution of Water Quality Monitoring

In the sectors of aquaculture, wastewater management, and environmental science, the transition toward high-precision, real-time monitoring is no longer optional—it is a requirement for operational efficiency. Traditional electrochemical sensors often struggle with the twin challenges of sensor drift and material degradation, especially in high-salinity or remote environments.

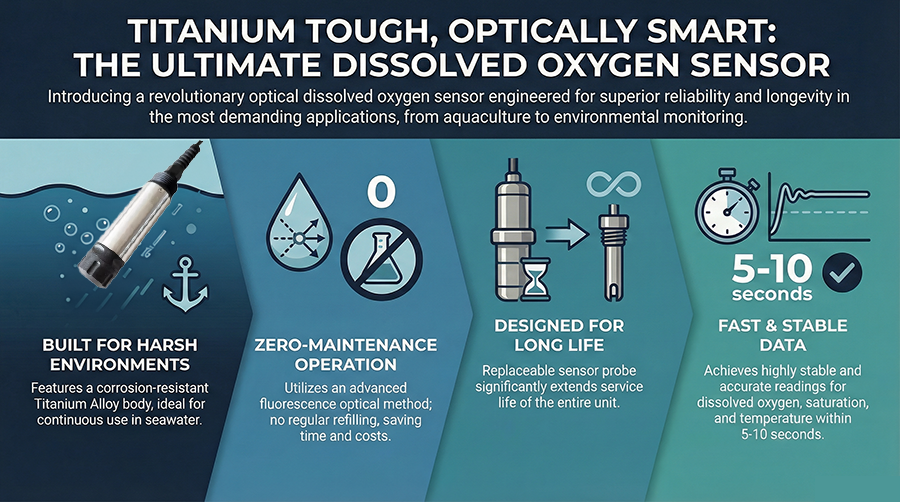

As a Senior IoT Solutions Architect, I have seen the industry shift toward integrated, ruggedized solutions. The core of this evolution is the Optical Dissolved Oxygen (DO) sensor constructed from titanium alloy, paired with a dedicated LoRaWAN collector. This system provides a sophisticated value proposition: extreme durability in corrosive seawater combined with long-range, low-power wireless data transmission, effectively solving the “last mile” connectivity problem in remote water monitoring.

2. Core Technology: Why Optical Fluorescence and Titanium Alloy?

The Fluorescence Principle

Unlike legacy galvanic or polarographic sensors that consume electrolytes and require frequent membrane replacements, this sensor utilizes the optical fluorescence method. By measuring the phase shift between the excitation and emission of a specialized fluorescent dye, the sensor determines oxygen concentration without consuming oxygen or chemicals. This results in a stable, maintenance-free sensing element that does not suffer from “poisoning” in hydrogen sulfide environments.

Titanium Alloy Housing

For long-term deployments, the material of the sensor body is as critical as the sensing element itself. The housing is constructed from high-grade titanium alloy, which provides superior resistance to corrosion compared to standard stainless steel. This makes the device uniquely suited for seawater and aggressive industrial effluents, ensuring structural integrity over years of immersion.

Replaceable Sensor Cap and Warranty

To maximize the lifecycle of the investment, the optical membrane head is fully replaceable. While the titanium body is designed for long-term permanence, the fluorescent membrane head comes with a one-year warranty under normal use, allowing for cost-effective maintenance without needing to replace the entire sensor assembly.

3. Detailed Technical Specifications

The following parameters define the operational boundaries and precision of the system. These specifications are critical for system integrators calculating data budgets and deployment depths.

|

Parameter

|

Specification

|

|---|---|

|

Measurement Principle

|

Fluorescence method

|

|

Measuring Range

|

0-50mg/L or 0-500% saturation

|

|

Accuracy

|

±5% or ±0.5mg/L (20mg/L); ±10% or ±1mg/L (>20mg/L)

|

|

Temperature Range & Accuracy

|

0-50°C / ±0.5°C

|

|

Waterproof Rating

|

IP68

|

|

Maximum Depth

|

30 meters

|

|

Output Signal

|

RS-485, Modbus Protocol

|

|

Power Supply

|

DC 5-24V (0.1W consumption)

|

|

Mounting Method

|

G3/4 thread, immersion mount

|

|

Cable Length

|

5 meters (default), customizable

|

|

Membrane Head Warranty

|

1 year (under normal use)

|

4. IoT Integration: The LoRaWAN Collector & Solar Power

Wireless Connectivity and Architecture

The sensor is integrated with a custom-made LoRa collector that serves as the communication bridge. This unit encapsulates the complexities of wireless transmission, sending data to a central LoRa gateway over several kilometers.

To streamline field deployment, all critical LoRa configuration information (IDs and credentials) is marked directly on the collector housing. This allows technicians to quickly import device profiles into the gateway without cross-referencing external spreadsheets.

Power Autonomy and Charging

Designed for true off-grid autonomy, the collector features a built-in solar panel and an integrated solar battery. For pre-deployment staging or troubleshooting, the unit includes a matched RS485-to-USB cable set. This connection allows for PC-end configuration and provides the ability to charge the internal battery via the PC connection if the unit has been stored away from sunlight.

Field Diagnostics

The hardware includes a physical switch equipped with a green light indicator. This serves as a vital diagnostic tool for boots-on-the-ground technicians: the light flashes during the initial power-on sequence and flashes again whenever data is being transmitted, providing visual confirmation of a successful uplink.

5. Key Advantages for Industrial Use

• Triple Measurement Output: The system provides a comprehensive data profile by simultaneously measuring temperature, dissolved oxygen (mg/L), and oxygen saturation (%).

• Rapid Stabilization: From a cold start, the data stabilizes within 5-10 seconds, enabling high-frequency sampling and responsive control of aeration systems.

• Maintenance-Free Design: The absence of reagents and consumable membranes significantly lowers the Total Cost of Ownership (TCO).

• Architectural Flexibility: Supports configurable salinity and pressure compensation, ensuring the data remains accurate across varying geographic and chemical contexts.

6. Target Applications: From Seawater to High Altitudes

The combination of advanced metallurgy and digital compensation allows this system to excel where others fail:

• Marine Aquaculture: The titanium alloy construction is specifically designed to resist the bio-fouling and corrosive nature of seawater, protecting fish and shrimp stocks in coastal pens.

• Environmental Monitoring: Ideal for tracking the health of rivers and lakes, providing the long-range connectivity needed for watershed-scale data collection.

• High-Altitude Deployments: Oxygen readings are sensitive to atmospheric pressure. This sensor includes configurable pressure compensation, which is the specific feature required to maintain measurement accuracy in high-altitude plateau regions or mountain lakes.

7. Conclusion: Scaling Water Intelligence with IoT

By merging the structural resilience of titanium with the low-power wide-area networking (LPWAN) capabilities of LoRaWAN, this sensing solution addresses the primary barriers to large-scale water monitoring: maintenance frequency, power availability, and environmental degradation.

The ability to deploy a maintenance-free, self-powered sensor in the most challenging environments—from corrosive salt marshes to high-altitude reservoirs—allows organizations to scale their water intelligence operations with confidence.

Contact our technical team for detailed system integration documentation or to discuss custom cable lengths for your specific deployment depth requirements.

For more sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Feb-02-2026