As competition intensifies in the craft beer industry, a Colorado-based brewery quietly completed a technological upgrade with staggering results: after installing dissolved CO₂ sensors, their product batch consistency improved by 35%, and yeast utilization efficiency increased by 22%. These figures spread rapidly through industry communities, sparking global brewing interest in this technology.

Core Technology: What Are Dissolved CO₂ Sensors?

Dissolved CO₂ sensors are precision instruments capable of real-time, continuous monitoring of carbon dioxide levels in liquids. During beer brewing, particularly in yeast filtration stages, dissolved CO₂ concentration directly affects yeast activity, fermentation efficiency, and final product quality. Traditional brewing relied on manual sampling and lab analysis with inherent delays and inaccuracies, whereas modern dissolved CO₂ sensors provide continuous, real-time data streams.

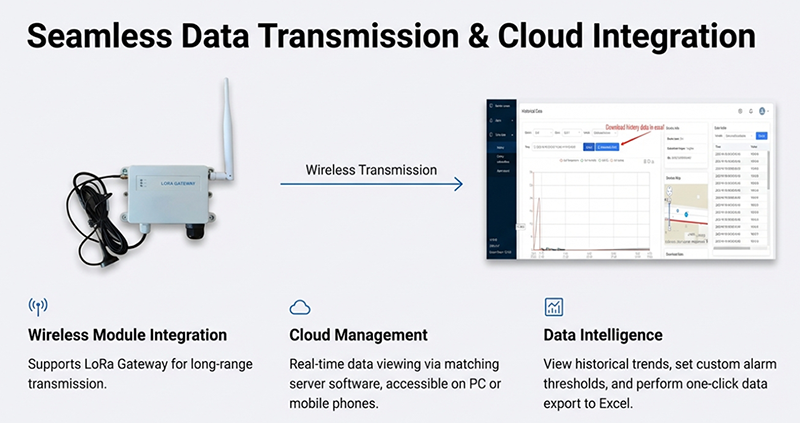

These sensors are typically integrated directly into filtration systems and fermentation tanks as probes, measuring CO₂ concentration through optical or electrochemical principles. Next-generation smart dissolved CO₂ sensors can even transmit data in real-time to control centers and mobile devices via IoT connectivity, enabling remote monitoring.

Precision Control in Yeast Filtration Systems

Yeast filtration is a critical stage determining beer quality. Excessive dissolved CO₂ can inhibit yeast activity, leading to incomplete fermentation, while insufficient levels may impact flavor development. Filtration systems equipped with specialized dissolved CO₂ sensor probes enable:

- Real-time parameter adjustment: Automatically modifying filtration speed and pressure based on dissolved CO₂ levels

- Optimized yeast recovery: Precisely controlling conditions to maximize active yeast recovery rates

- Quality issue prevention: Instantly detecting anomalies to avoid entire batch losses

A traditional Belgian Trappist brewery reported that after integrating dissolved CO₂ sensors into fermentation tanks and filtration systems, their seasonal beer flavor consistency reached unprecedented levels, with minimal product variation even under different climatic conditions.

Industry Applications and Data Validation

A recent white paper from the California Craft Brewers Association revealed that member breweries using dissolved CO₂ sensors averaged:

- 47% reduction in yeast-related production losses

- 18% shorter batch cycle times

- 15% improved energy efficiency (cooling/heating requirements)

“Dissolved CO₂ sensors provide data that lets us truly ‘see’ the fermentation process for the first time,” explained a master brewer in an interview. “We no longer rely on guesswork and experience but make precise decisions based on real-time data.”

Technical Challenges and Innovative Breakthroughs

Despite their advantages, early dissolved CO₂ sensor applications faced challenges including calibration complexity, hygienic design requirements, and long-term stability. The latest sensor generation addresses these through:

- Self-cleaning and auto-calibration functions

- Food-grade hygienic material design

- Contamination-resistant optical measurement technology

- AI-driven predictive maintenance

Market Outlook and Industry Impact

According to global brewing equipment market analysis, smart filtration systems integrated with dissolved CO₂ sensors are becoming the new industry standard. Major equipment manufacturers are launching built-in sensor solutions, while independent sensor suppliers report surging demand.

On social media, under the hashtag #DissolvedCO2Sensors, brewers, process engineers, and craft beer enthusiasts share application experiences and comparative results. A technical video demonstrating how sensors prevent entire beer batch losses garnered over 2 million views on TikTok.

Future Prospects: Beyond Beer Brewing

While dissolved CO₂ sensors have gained attention in beer brewing, their application potential extends far beyond. Similar technological principles are expanding into carbonated beverage production, winemaking, biopharmaceuticals, and even aquaculture. As sensor costs decrease and intelligence capabilities improve, real-time dissolved gas monitoring may become standard in numerous liquid processing industries.

Industry experts predict: Within five years, over 60% of medium-to-large breweries will deploy dissolved CO₂ sensors at critical process points, with this technology becoming a core component of “Industry 4.0″ breweries.

Conclusion

In the pursuit of brewing excellence, dissolved CO₂ sensors have evolved from novel technology to essential quality control tools. They serve not only as data collection devices but as bridges connecting traditional craftsmanship with modern science, ensuring every glass of beer achieves its intended flavor and quality standards. As technology advances and costs optimize, dissolved CO₂ sensors are poised to become standard equipment in global brewing, redefining the boundaries of quality control.

Tags: dissolved co2 sensor、dissolved carbon dioxide sensor probe 、beer yeast filtration system

For more water sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

DissolvedCO2Sensors | BrewingTechRevolution | BeerQualityControl | SmartBrewingSystems | YeastManagementInnovation

Has your brewing process integrated dissolved CO₂ monitoring technology? Share your experiences or questions in the comments below – industry experts are online to respond!

Post time: Jan-20-2026