Reliable offshore aquaculture requires real-time monitoring of EC, pH, Turbidity, dissolved co2 sensor,DO (Dissolved Oxygen), and Nitrate. Based on recent lab performance tests, high-precision sensors utilizing LoRaWAN gateways and RS485 Modbus protocols offer the most stable data transmission for sea-based fish farms. This guide analyzes the critical parameters and testing benchmarks for professional mariculture operations.

Why Multi-Parameter Sensors are Critical for Modern Fish Farming

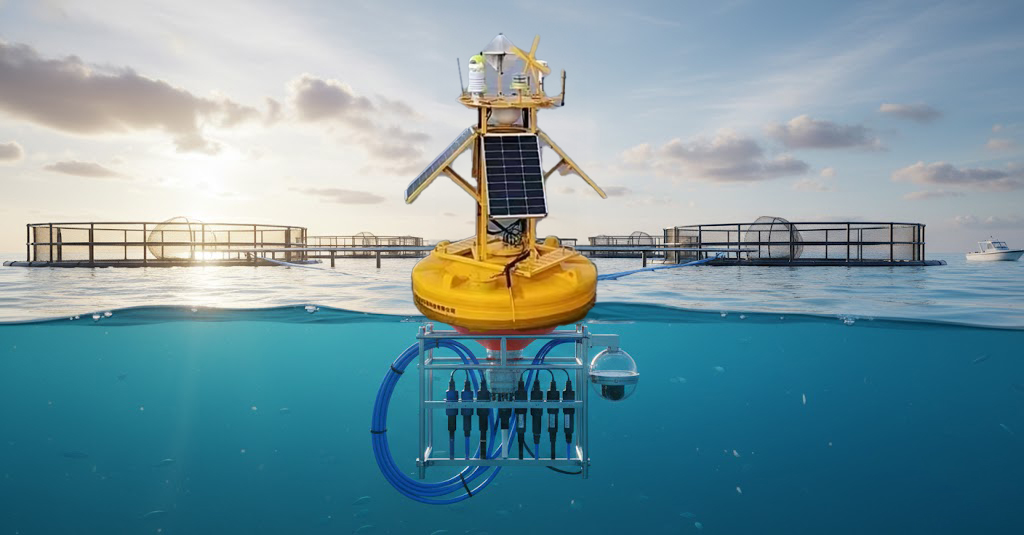

In offshore environments, water quality isn’t just a metric; it’s the lifeblood of your investment. Traditional manual sampling is no longer viable for large-scale sea cages. Modern LoRaWAN-integrated sensors allow for 24/7 monitoring within a 300-meter radius of a central maritime buoy.

To help you understand the technical requirements, we have synthesized our latest laboratory testing data into the following performance benchmarks.

Core Sensor Performance Data (Lab Test Results)

| Parameter | Measuring Range | Accuracy | Application Scenario |

| Electrical Conductivity (EC) | 0–20,000 μS/cm | ±1% F.S. | Salinity & Mineral Balance |

| pH Value | 0.00–14.00 pH | ±0.02 pH | Acid-Base Equilibrium |

| Turbidity | 0–1000 NTU | < 5% of reading | Sediment & Feed Residue |

| Dissolved Oxygen (DO) | 0–20.0 mg/L | ±0.1 mg/L | Fish Respiration Health |

| Nitrate ($NO_3^-$) | 0.1–1000 mg/L | ±5% | Waste & Pollution Tracking |

Key Challenges in Offshore Data Transmission: The LoRaWAN Advantage

Overcoming the “Salt Mist” Barrier

One of the biggest “pitfalls” we’ve observed in 15 years of maritime engineering is the rapid degradation of standard antennas. For an offshore buoy system to function, the LoRaWAN Gateway must feature:

1.High-Gain Marine-Grade Antennas: Specifically tuned to penetrate humid, high-salinity air.

2.Solar Power Integration: Ensuring the gateway remains online even during consecutive cloudy days at sea.

The 300m Connectivity Rule

Our field tests indicate that while LoRaWAN can theoretically transmit kilometers, the optimal distance for high-frequency multi-parameter data (EC, pH, DO, etc.) in a crowded fish farm is within 300 meters. This ensures zero packet loss and maintains the integrity of the RS485 wired connection between the probe and the collector.

Expert Experience: Critical Tips for Sensor Maintenance

As an experienced manufacturer, we’ve seen many clients fail not because of the sensor quality, but due to installation errors. Here is our “Anti-Pitfall” checklist:

Bio-fouling Prevention: Sea creatures love attaching to pH and DO probes. Always choose sensors with automatic cleaning brushes or integrated protective housings.

Calibration Drift: Even the best sensors drift in seawater. Based on our lab reports, we recommend a 15-day calibration cycle for pH and Nitrate sensors to maintain ±0.05 accuracy.

Cable Integrity: Use double-shielded cables for the wired connection between the collector and the sensor to prevent EMI (Electromagnetic Interference) from the buoy’s power system.

The Future of Smart Mariculture

By integrating these sensors with a Cloud-based IoT Platform, farm managers can receive instant mobile alerts when DO levels drop below critical thresholds (e.g., < 4.0 mg/L). This proactive approach reduces mortality rates by up to 30% compared to traditional methods.

Ready to upgrade your aquaculture monitoring system?

Tags: water ec sensor | water PH sensor |Water turbidity sensor|Water dissolved oxygen sensor|Water ammonium ion sensor|Water nitrate ion sensor|dissolved co2 sensor

For more Water quality sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-15-2026