1. Introduction: The Invisible Metric in Liquid Management

In modern industrial liquid management, carbon dioxide is the invisible metric that dictates the thin line between a high-value batch and a total loss. Whether it is a massive aquaculture facility or a high-output beverage plant, CO2 levels are a critical determinant of biological health and sensory profiles. For beverage producers—especially in beer, cola, and carbonated drink sectors—maintaining the “original taste” is not just about quality; it is about brand protection.

The Honde dissolved co2 sensor represents a paradigm shift from reactive manual testing to proactive, automated monitoring. By implementing a high-accuracy Water carbon dioxide sensor, operators can move away from the high “cost of inaction”—such as catastrophic fish mortality in aquaculture or compromised shelf-life in bottling—to a data-driven model that ensures maximum yield and product consistency.

2. Technical Specifications & Precision Grounding

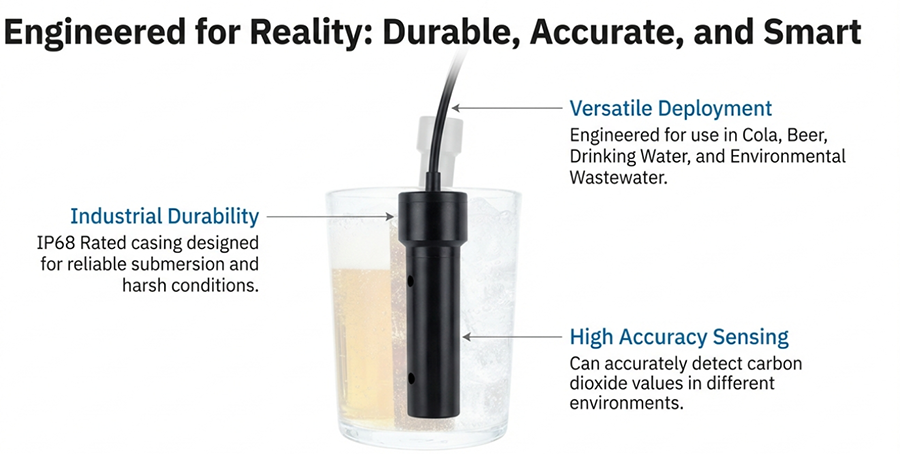

Industrial reliability is built on a foundation of rigorous technical standards. The Honde sensor is engineered to provide granular data in the most demanding environments.

|

Feature

|

Specification

|

|---|---|

|

Product Name

|

Honde Dissolved Carbon Dioxide Sensor

|

|

Measuring Range

|

2000 ppm (Customizable options available)

|

|

Measuring Accuracy

|

± (20PPM + 5% reading)

|

|

Resolution

|

1 ppm

|

|

Operating Temperature

|

-20 to 60°C

|

|

Operating Humidity

|

0-90% RH

|

|

Operating Pressure

|

0.8-1.2 atm

|

|

Power Supply

|

9-24VDC

|

Beyond the numbers, the hardware is housed in an IP68 industrial-grade enclosure. This ensures the sensor is completely dust-tight and rated for continuous immersion, providing long-term stability in corrosive saline environments or high-pressure industrial tanks where generic sensors typically fail.

3. The Power of Connectivity: The IoT CO2 Sensor Advantage

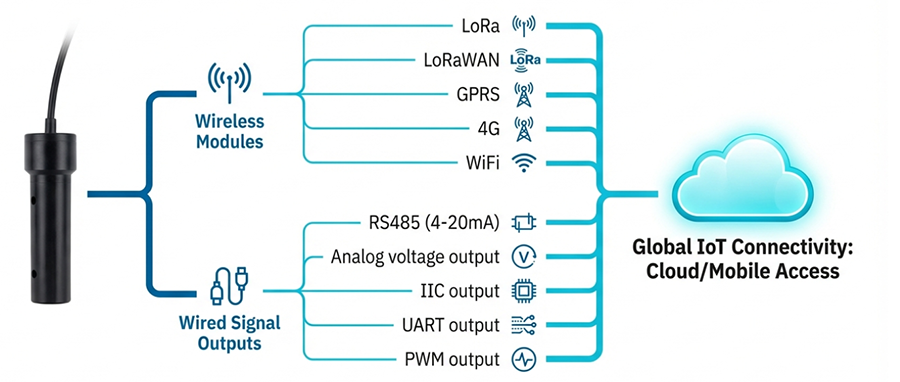

The strategic advantage of the iot co2 sensor lies in its communication versatility. It is no longer enough to have data; that data must be accessible, actionable, and scalable.

Wireless Protocols for Global Scalability

The Honde sensor integrates seamlessly with diverse wireless modules to fit any infrastructure:

• LoRa & LoRaWAN: Ideal for large-scale aquaculture operations, offering long-range connectivity with minimal power consumption.

• GPRS & 4G: Provides robust, independent connectivity for remote environmental monitoring stations.

• WIFI: Perfect for localized, high-speed data transmission within smart factory environments.

Cloud Integration & Signal Versatility

The system matches with proprietary cloud servers and software, enabling stakeholders to monitor levels in real-time via PC or mobile phone. For integration into existing SCADA or PLC systems, the sensor supports a professional array of signal outputs:

• Digital: RS485 (Modbus), IIC, UART, PWM

• Analog: 4-20mA Analog Current Loop, Analog Voltage

4. Multi-Industry Application Scenarios

The Honde sensor is a versatile tool across several high-stakes sectors:

• Beverage & Drinking Water: Essential for beer yeast filtration and the manufacturing of cola and carbonated drinks. It ensures the precise carbonation levels required for the “original taste” and prevents flavor degradation.

• Aquaculture & Environment: Used in water quality monitoring to prevent CO2 toxicity in fish and shrimp farming. It also serves a dual purpose in agricultural greenhouses to monitor environmental CO2 affecting plant growth.

• Pharmaceutical & Solution Analysis: Provides the 1 ppm resolution necessary for precise medical laboratory work and pharmaceutical solution analysis, where chemical stability is non-negotiable.

5. Strategic Checklist: What to Look for in a Sensor

When evaluating sensors for a B2B environment, prioritize features that reduce total cost of ownership (TCO) and operational expenditure (OPEX):

• Environmental Durability (IP68): Essential for minimizing maintenance overhead and sensor replacement frequency in permanent-immersion scenarios.

• IoT Scalability: Look for LoRaWAN and 4G options to ensure the system can grow from a single tank to a multi-site operation without infrastructure overhauls.

• Software Compatibility: Prioritize sensors with matching cloud software support to allow for instant data visualization and automated threshold alerts.

• Operational Versatility: Ensure the sensor can handle the pressure (0.8-1.2 atm) and temperature (-20 to 60°C) swings inherent in industrial processes.

6. Conclusion & Future Outlook

The integration of iot co2 sensor technology is no longer a luxury—it is a requirement for competitive industrial efficiency and sustainability. By removing the guesswork from liquid management, the Honde dissolved CO2 sensor empowers operators to protect their bottom line, ensure environmental safety, and maintain the highest standards of product quality.

As industries move toward AI-driven automation, the shift to data-driven liquid management will be the defining factor in operational success. Investing in precision instrumentation today is the key to mastering the invisible metrics of tomorrow.

Tags: dissolved co2 sensor、Water carbon dioxide sensor 、iot co2 sensor

For more water sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-22-2026