1. Introduction: The Revolution in Beverage Precision

In the world of high-stakes brewing and bottling, carbon dioxide is more than just “fizz”—it is the soul of the beverage. For Beer, Cola, and Carbonated drinks, CO2 levels dictate mouthfeel, shelf-life, and flavor stability. In the past, precision was a luxury; today, it is a requirement. This dissolved carbon dioxide sensor acts as a game-changer for quality control, moving beyond manual sampling to automated, high-sensitivity detection. By accurately monitoring values in fluctuating environments, you ensure the “Original Taste” intended by your master brewer reaches the consumer’s glass every single time.

2. Product Overview:

The High-Precision Probe Engineered for the rigorous demands of a modern production floor, this Dissolved Carbon Dioxide Sensor is built for high precision and maximum uptime.

Quick Wins:

- High Precision and Sensitivity: Detects even the slightest deviations to prevent batch inconsistencies (Image 3).

- Fast Response & Low Power Consumption: Real-time data updates with minimal energy draw, perfect for 24/7 monitoring (Image 4).

- Long-Lasting Durability: Robust construction designed to survive the harsh cleaning cycles of a brewery (Image 5).

- IP68 Waterproof Rating: Fully submersible. You can put the probe into the water or beverage directly for instantaneous testing (YouTube Transcript).

3. Technical Specifications Table

For process engineers integrating this unit into a “Smart Factory” environment, here are the core technical requirements:

|

Feature

|

Specification

|

|---|---|

|

Product Name

|

Dissolved carbon dioxide sensor

|

|

Measuring Range

|

2000 ppm (Customizable options available)

|

|

Accuracy

|

± (20PPM + 5% reading)

|

|

Resolution

|

1 ppm

|

|

Operating Temp

|

-20°C to 60°C

|

|

Operating Pressure

|

0.8 – 1.2 atm

|

|

Operating Humidity

|

0 – 90% RH

|

|

Power Supply

|

9 – 24V DC

|

|

Signal Output (Digital)

|

RS485 (Modbus RTU), IIC, AURT/UART

|

|

Signal Output (Analog)

|

4-20mA, Analog Voltage, PWM

|

4. Advanced Connectivity & Cloud Monitoring

To stay competitive, your data needs to be as mobile as you are. This sensor doesn’t just measure; it communicates.

1. Industrial Wireless Modules: Fully compatible with GPRS, 4G, WIFI, LORA, and LORAWAN for flexible facility-wide deployment.

2. LORA Gateway Integration: Match your sensors with a LORA Gateway to push data directly to cloud servers, enabling a true “Smart Brewery” ecosystem.

3. Real-Time Data Visualization: View live readings (such as the 946 ppm example from our field tests) on your PC or mobile phone instantly.

4. Process Analysis: Download historical data directly into Excel. This allows engineers to perform deep-dive trend analysis to identify where CO2 loss occurs in the production cycle.

5. Application Spotlight: Beer Yeast Filtration System

The Critical Gatekeeper: Beer Yeast Filtration During the filtration stage, beer is at its most vulnerable. Pressure fluctuations—specifically those hitting the 0.8-1.2 atm range—can cause CO2 to “break out” of the solution. This leads to excessive foaming, oxidation, and a loss of the beverage’s “Original Taste.”

By utilizing this sensor in your beer yeast filtration system, you gain a real-time defense against these fluctuations. Maintaining precise CO2 saturation at this stage ensures consistent head retention and protects the aromatic integrity of the hops, effectively gatekeeping the quality of your brand.

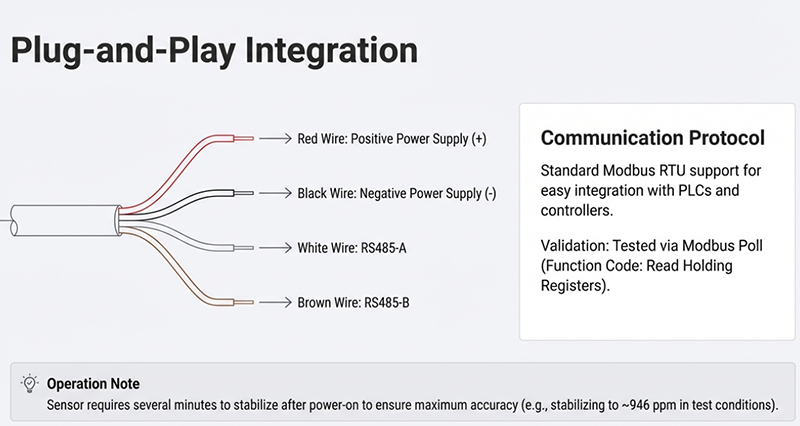

6. Installation & Wiring Guide (The Modbus Advantage)

The sensor utilizes the industry-standard Modbus protocol, ensuring seamless integration with existing PLC systems. For initial testing, an RS485 to USB connector is recommended.

Color-Coded Wiring System:

- Red: Positive Power Supply (+)

- Black: Negative Power Supply (-)

- White: RFA (A)

- Brown: RFB (B)

Engineering Tip:

Use “Modbus Poll” software for initial configuration. Set the Sensor ID to 20 (default) to begin reading PPM values. Note that the sensor requires several minutes to stabilize after initial submersion to provide the most accurate reading.

7. Frequently Asked Questions (FAQ)

Q: Can the sensor be submerged directly in the fermentation or filtration tank?

A: Absolutely. With an IP68 waterproof rating, the probe is designed to be put into the water or beverage directly without any additional housing required.

Q: What if my process exceeds the 2000 ppm range?

A: While the standard range is 2000 ppm, we offer customizable measuring ranges to suit high-carbonation soda products or specific laboratory needs.

Q: How do I access data if I am off-site?

A: By matching the sensor with our cloud server and a wireless module (like 4G or WIFI), you can monitor your levels in real-time via any mobile device or PC.

8. Call to Action (CTA)

Maximize your brewery’s efficiency and protect your “Original Taste.” Upgrade your beer yeast filtration system with the ultimate dissolved CO2 sensor today. With a Minimum Order Quantity (MOQ) of just 1 PC, high-precision quality control is now accessible to every craft brewer and industrial bottler.

Conclusion:

Besides its application in beer fermentation, the dissolved carbon dioxide sensor can also be used in aquaculture, water quality monitoring, environmental monitoring of agricultural greenhouses, solution analysis, pharmaceutical and environmental monitoring, food and beverage, and beer yeast filtration systems.

Tags: dissolved co2 sensor、dissolved carbon dioxide sensor probe 、beer yeast filtration system

For more water sensor information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

Post time: Jan-20-2026