1. Introduction: Addressing Global Water Management Needs

In the landscape of Industrial IoT (IIoT), the shift from reactive to predictive water management is no longer a luxury—it is a necessity. As global demand for precise monitoring intensifies, industries are rapidly abandoning traditional mechanical float sensors, which are prone to fouling and mechanical failure, in favor of intelligent electronic solutions.

From a strategic perspective, this transition is driven by the bottom line. For instance, a food processing plant recently leveraged networked electronic water level sensors to enable predictive maintenance on its cooling system. By preventing a single catastrophic overflow, the facility saved over $50,000 in potential losses and structural damage. This article provides a technical deep dive into the features, specifications, and applications of the next-gen electronic water level gauge—the digital sentinel of modern water infrastructure.

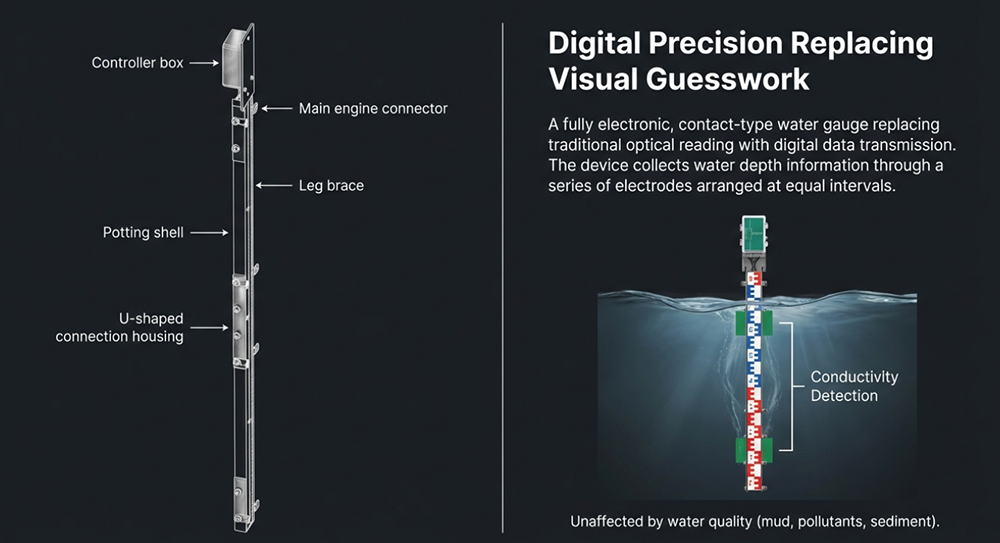

2. Product Principle: The Science of Precision

This electronic water level sensor—often referred to as a “ruler-style” or “strip” sensor due to its sleek, vertical form factor—operates on advanced electrode-based sensing technology. Unlike ultrasonic sensors, which can be compromised by foam and vapor, or pressure sensors that require frequent cleaning and recalibration, this device offers “full range equal precision.”

The Conductivity-Based Judgment Process

The sensor collects water depth information through a series of electrodes arranged at equal, precise intervals. The internal collection circuit monitors the potential status of these electrodes; as water rises, the conductivity of the liquid changes the status of the submerged electrodes. The built-in microprocessor then calculates the exact depth based on the number of submerged points.

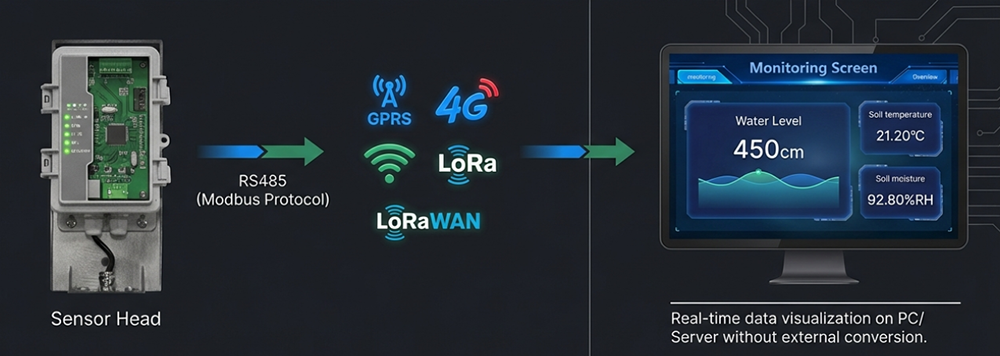

Key Advantage: Absolute Data Output Unlike analog sensors that output raw voltage or current requiring software scaling, this device provides “data without conversion.” It outputs an absolute digital value (e.g., 50cm), ensuring immediate, high-fidelity integration into PLC or IoT environments.

Key Takeaway: The industry standard for accuracy is defined by the sensor’s 1cm default resolution (customizable to 0.5cm), providing consistent precision across the entire measuring range.

3. Hardware Components & Modular Mechanics

For engineers and installers, the physical integrity of the sensor is as critical as its digital output. The device is built with a focus on industrial-grade durability and field serviceability:

• Stainless Steel Shell: The outer casing is constructed from high-quality stainless steel, ensuring resistance to impact and harsh environmental conditions.

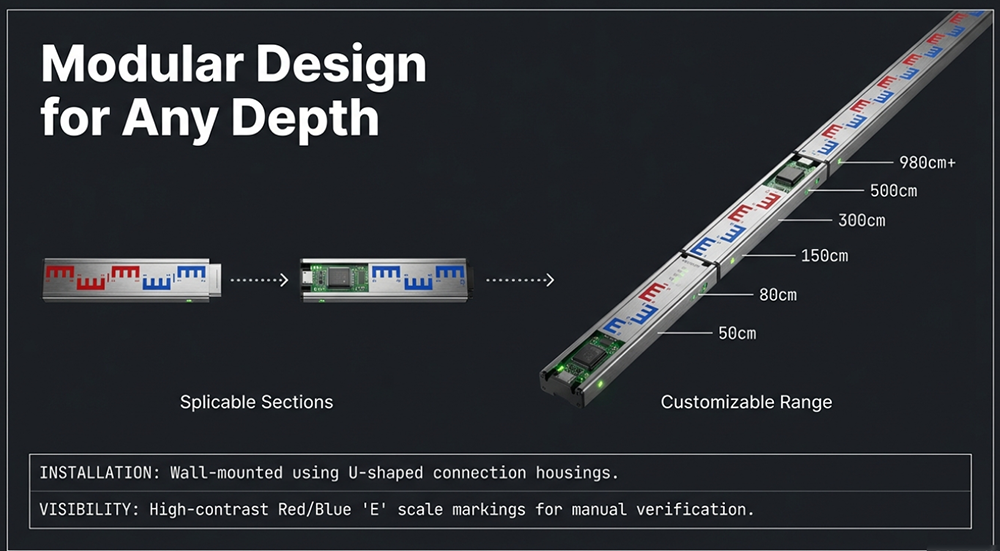

• Modular Assembly: The sensor utilizes a highly flexible modular design. Users can combine 50cm and 80cm sections using U-shaped connection housings and M10 mounting screws to reach customized ranges up to 980cm.

• Black Potting Compound: The internal electronics are encased in a specialized black potting compound, which provides superior waterproofing and protects against signal interference.

• Robust Mounting: The unit includes a U-shaped top cover, U-shaped bottom jacket, and leg braces for secure wall-mounted installation.

4. Advanced Features & Technical Advantages

• Intelligent Microprocessor: Serves as the central controller with built-in communication circuits and lightning protection to safeguard data during extreme weather.

• Environmental Resilience: The high-performance sealing materials are specifically treated for aging, heat, freezing, and corrosion resistance.

• Protection Classes: The system is designed for varied exposure—the Host (controller box) is rated IP54, while the Slave (sensing ruler) is rated IP68, allowing for permanent submersion in contaminated or corrosive liquids.

• Local Control via Integrated Relay: Uniquely, the product includes a built-in relay. This allows for hardware-level fail-safes, such as directly triggering a pump or local alarm without the need for an intermediary PLC.

5. Technical Specifications Table

The following data sheet represents the standard configuration for the electronic water level sensor.

Technical Data Sheet

|

Parameter

|

Specification

|

|---|---|

|

Power Supply

|

DC 10–30V (Default)

|

|

Accuracy / Resolution

|

1cm (Full range equal precision) / 0.5cm (Custom)

|

|

Standard Output

|

RS485 (Modbus protocol)

|

|

Optional Wireless Support

|

GPRS, 4G, Lora, Lorawan, WIFI

|

|

Configuration Software

|

Provided software for configuration via Port 485

|

|

Host Power Consumption

|

< 0.8W

|

|

Slave Power Consumption

|

< 0.05W per section

|

|

Protection Class

|

Host: IP54 / Slave: IP68

|

|

Installation Mode

|

Wall-mounted

|

|

Physical Dimensions

|

Hole size: 86.2mm / Punch size: 10mm

|

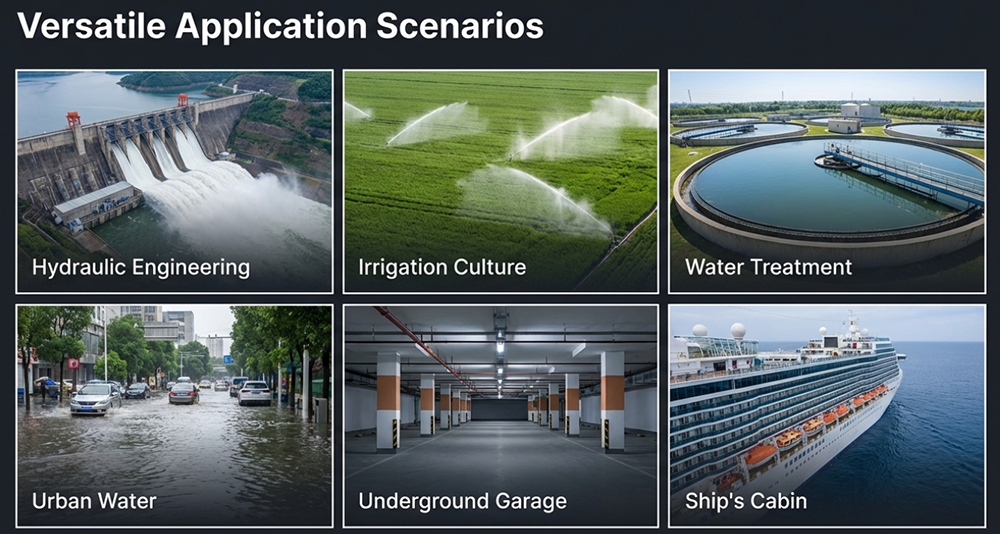

6. Real-World Applications: From Smart Cities to Industrial Hubs

With its integrated relay and support for PC-end data visualization, this sensor is a versatile tool across multiple industries:

• Water Conservancy: Real-time monitoring of reservoirs, rivers, and hydropower stations.

• Municipal Engineering: Flood monitoring for urban roads, tap water management, and sewage treatment.

• Commercial & Industrial: Leak detection and level control in underground garages, shopping malls, and ship cabins.

• Agriculture: Precision irrigation and aquaculture monitoring, where “data without conversion” allows for rapid automated response.

7. Frequently Asked Questions (FAQ)

Q: How does the sensor handle mud or corrosive liquids?

A: The sensor is engineered with a stainless steel shell and high-performance sealing. Unlike optical sensors, it is not affected by lens contamination, mud, pollutants, or precipitates.

Q: Is the length limited to standard sizes?

A: No. The range is highly customizable. Using the modular U-shaped connection housings, you can combine 50cm and 80cm sections to reach any length up to 980cm.

Q: What are the remote monitoring options?

A: While RS485 (Modbus) is standard for local PLC integration, we offer optional modules for 4G, Lora, and GPRS to connect directly to cloud platforms and PC-based visualization software.

Q: How is the device configured for specific site requirements?

A: Configuration is handled via the provided dedicated software through the RS485 port, allowing for easy adjustment of parameters without complex hardware manipulation.

8. Conclusion & Action Guide

The electronic water level sensor has evolved from a simple gauge into a critical perceptual node for “Water Intelligence.” By providing absolute, digital data in the harshest environments, it acts as the cornerstone for smart city and industrial automation.

Action Guide

• For Business Managers: Audit your current liquid management systems. If you rely on mechanical floats or un-networked gauges, upgrade to an IoT-enabled sensor network. The ROI from preventing a single overflow event (as seen in the $50k food plant case) far outweighs the initial CAPEX.

• For Developers & System Integrators: Utilize the RS485/Modbus output to feed data into MQTT gateways for cloud analytics. Leverage the built-in relay to design hardware-level fail-safes that operate independently of the primary software logic.

Tags: Electronic water level sensor |Water level sensor

For more WATER LEVEL SENSOR information,

please contact Honde Technology Co., LTD.

WhatsApp: +86-15210548582

Email: info@hondetech.com

Company website: www.hondetechco.com

#Water Tech #IoT #SmartCity #Industrial Automation #Water Management

Post time: Jan-16-2026